- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

LQ

UPG

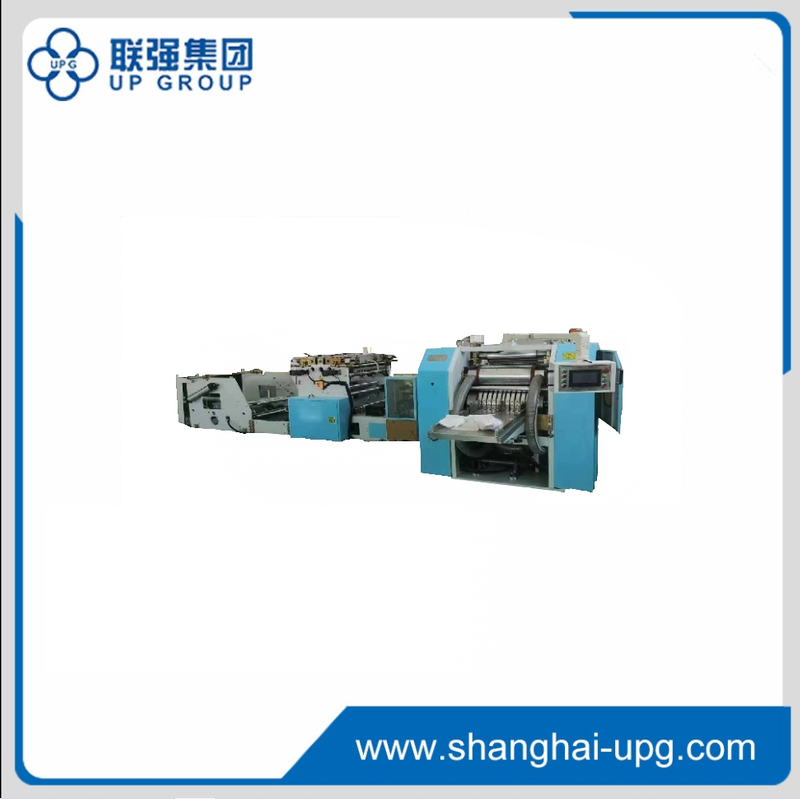

LQ-4L 1/4、1/6、1/8 Air suction dispenser napkin folder adopt the vacuum suction fold then through embossed and cut off 1/8 folder napkin. This machine include frequency conversion speed adjustment, timing belt and electronic counting function, which is the ideal equipment for production of top grade napkins.

1. The bottom embossing rolls can be covered with wool-cloth, neoprene, or wool-paper material(depending on the needs of customers).

2. Pneumatic loading of jumbo reel can greatly reduce the working tension.

3. A variable-cutting width of finished product range from 100-210mm can be easily affected on the machine by adjusting the round cutting blades.

4. Automatic detection of paper break and paper wrap up: to guarantee the high quality of the finished rolls even in the high speed operation

5. The web can be threaded on the machine by the two jog buttons, It's more safety and easier to feed the web

LQ-4L 1/4、1/6、1/8 Air suction dispenser napkin folder adopt the vacuum suction fold then through embossed and cut off 1/8 folder napkin. This machine include frequency conversion speed adjustment, timing belt and electronic counting function, which is the ideal equipment for production of top grade napkins.

1. The bottom embossing rolls can be covered with wool-cloth, neoprene, or wool-paper material(depending on the needs of customers).

2. Pneumatic loading of jumbo reel can greatly reduce the working tension.

3. A variable-cutting width of finished product range from 100-210mm can be easily affected on the machine by adjusting the round cutting blades.

4. Automatic detection of paper break and paper wrap up: to guarantee the high quality of the finished rolls even in the high speed operation

5. The web can be threaded on the machine by the two jog buttons, It's more safety and easier to feed the web

Unit | Specification |

Suitable Material | Single Layer: 16-25g/㎡;Double Layer: 12-19g/㎡High humidity strong original paper |

| Paper size and width | φ1500mmX1100mm |

| Paper core diameter | φ76mm |

Folding Type | 1/6 Dislocation Folding |

Product Size | Open size: 300mm(90mm*2+120mm)x275mm(165mm+110mm) Finish size:165mmx120mm |

Paper Feeding Unit | Single layer paper feeding,use the wide belt for the feeding, one paper shaft |

Paper left and right adjusting by hand,Pneumatic paper lifting | |

Quick paper changing device | |

Transmission Unit | Independent variable frequency |

Independent motor, independent drive | |

The whole machine use timing belt to drive step by step | |

Printing Unit | Closed type doctor blade system |

Circulating ink supply system | |

Ceramic anilox roller (Plate roller is with gridlines, Ceramic anilox roller LPI: 300 lines | |

Embossing Unit | Steel roller with the felt roller for embossing,Embossing clear and unstratified, not crushing paper, no wrinkle (Pattern provided from the customer) |

Mechanical pressure control makes the pressure accurate and balanced | |

Felt with the oil for dust cleaning ( use white mineral oil) | |

Folding Unit | The gap between the folding roller and pull roller can be adjusted |

Counting function, adopt the pneumatic dislocation type | |

Design speed: 500pcs/min/lane Production speed: 400pcs/min/lane Production speed with printing: 350 pcs/min/lane | |

Control Unit | Frequency converter【INVT】 |

Automatic counting function | |

The machine will automatically stop when paper breaking | |

Power:AC380V 50HZ Main motor: 7.5KW Vacuum pump: 18.5KW(Taiwan) | |

Component Brand | Important part use NSK high temperature resistance bearing |

Low-voltage electrical apparatus【Brand: Schneider 】 Photoelectricity【Brand: Omron】 Frequency converter【Brand: INVT】 | |

Pneumatic component【Brand: AIRTAC】 | |

Air cylinder【Brand: JAC】 | |

·

| Paper cutting off base knife and face knife: each 2 pieces Scratcher:5 pieces Slitting base knife: 2 pieces Paper sending belt: 2 pieces, with 2pcs paper shaft |

Tool box | |

Documents | Machine operating manual【including the power, air diagram and installation instruction】 |

Frequency converter use manual | |

Using manual and common accessories details |

Unit | Specification |

Suitable Material | Single Layer: 16-25g/㎡;Double Layer: 12-19g/㎡High humidity strong original paper |

| Paper size and width | φ1500mmX1100mm |

| Paper core diameter | φ76mm |

Folding Type | 1/6 Dislocation Folding |

Product Size | Open size: 300mm(90mm*2+120mm)x275mm(165mm+110mm) Finish size:165mmx120mm |

Paper Feeding Unit | Single layer paper feeding,use the wide belt for the feeding, one paper shaft |

Paper left and right adjusting by hand,Pneumatic paper lifting | |

Quick paper changing device | |

Transmission Unit | Independent variable frequency |

Independent motor, independent drive | |

The whole machine use timing belt to drive step by step | |

Printing Unit | Closed type doctor blade system |

Circulating ink supply system | |

Ceramic anilox roller (Plate roller is with gridlines, Ceramic anilox roller LPI: 300 lines | |

Embossing Unit | Steel roller with the felt roller for embossing,Embossing clear and unstratified, not crushing paper, no wrinkle (Pattern provided from the customer) |

Mechanical pressure control makes the pressure accurate and balanced | |

Felt with the oil for dust cleaning ( use white mineral oil) | |

Folding Unit | The gap between the folding roller and pull roller can be adjusted |

Counting function, adopt the pneumatic dislocation type | |

Design speed: 500pcs/min/lane Production speed: 400pcs/min/lane Production speed with printing: 350 pcs/min/lane | |

Control Unit | Frequency converter【INVT】 |

Automatic counting function | |

The machine will automatically stop when paper breaking | |

Power:AC380V 50HZ Main motor: 7.5KW Vacuum pump: 18.5KW(Taiwan) | |

Component Brand | Important part use NSK high temperature resistance bearing |

Low-voltage electrical apparatus【Brand: Schneider 】 Photoelectricity【Brand: Omron】 Frequency converter【Brand: INVT】 | |

Pneumatic component【Brand: AIRTAC】 | |

Air cylinder【Brand: JAC】 | |

·

| Paper cutting off base knife and face knife: each 2 pieces Scratcher:5 pieces Slitting base knife: 2 pieces Paper sending belt: 2 pieces, with 2pcs paper shaft |

Tool box | |

Documents | Machine operating manual【including the power, air diagram and installation instruction】 |

Frequency converter use manual | |

Using manual and common accessories details |