- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

TYM1020-H

UPG

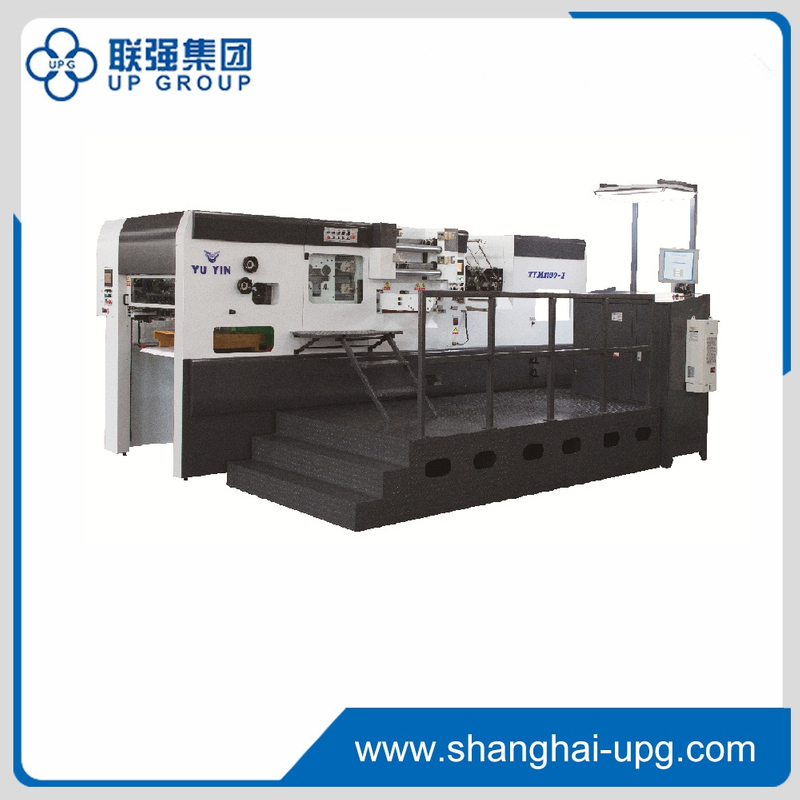

| TYM1020-H automatic foil stamping and diecutting machine | |

TYM1020-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. This kind of machine is a new generation of foil stamping series on the basis of TYM1020, it’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliability, high speed, press and precision. | |

● Longitudinal and lateral foil stamping devices are equipped which make foil stamping process more reasonable. electrical cabinetFoil stamping control systemMotorized pressure adjustingelectrical cabinetFoil stamping control systemMotorized pressure adjusting |

| TYM1020-H automatic foil stamping and diecutting machine | |

TYM1020-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. This kind of machine is a new generation of foil stamping series on the basis of TYM1020, it’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliability, high speed, press and precision. | |

● Longitudinal and lateral foil stamping devices are equipped which make foil stamping process more reasonable. electrical cabinetFoil stamping control systemMotorized pressure adjustingelectrical cabinetFoil stamping control systemMotorized pressure adjusting |

| Max. Paper Size | 1020×720mm |

| Min. Paper Size | 400×360mm |

| Max. Diecutting Size | 1010×710mm |

| Max. Foil Stamping Size | Longitudinal: 970×685mm Lateral: 960×580mm |

| Max. Diecutting Speed | 6500s/h |

| Max. Stamping Speed | 5000s/h |

| Max. Pressure | 250 T |

| Max. Foil Diameter | Ф195mm/3″ Ф100mm/1″ |

| Sheet Thickness | Cardboard:0.1-1.5mm Corrugated paper:≤4mm |

| Net Weight | 18.5 T |

| Total Power | 46.5kw |

| Quantities Of Heating Area | 12 |

| Diecutting Precision | ±0.1mm |

| Overall Dimension | 5470×3940×2585mm |

| Max. Paper Size | 1020×720mm |

| Min. Paper Size | 400×360mm |

| Max. Diecutting Size | 1010×710mm |

| Max. Foil Stamping Size | Longitudinal: 970×685mm Lateral: 960×580mm |

| Max. Diecutting Speed | 6500s/h |

| Max. Stamping Speed | 5000s/h |

| Max. Pressure | 250 T |

| Max. Foil Diameter | Ф195mm/3″ Ф100mm/1″ |

| Sheet Thickness | Cardboard:0.1-1.5mm Corrugated paper:≤4mm |

| Net Weight | 18.5 T |

| Total Power | 46.5kw |

| Quantities Of Heating Area | 12 |

| Diecutting Precision | ±0.1mm |

| Overall Dimension | 5470×3940×2585mm |