| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-ZP-400

UPG

Introduction:

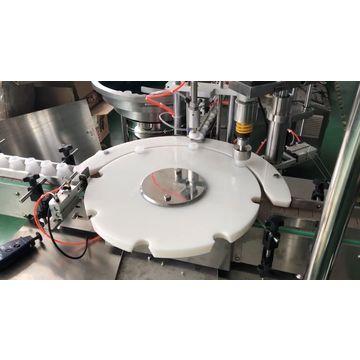

This automatic rotary plate capping machine is our new designed product recently. It adopts rotary plate to positioning the bottle and capping. The type machine is widely used in packaging cosmetic, chemical, foods, pharmaceutical, pesticides industry and so on. Besides plastic cap, it is workable for the metal caps as well.

Process:

Bottle in → Feeding cap → Put the cap on the bottle → Capping →Bottle out

Feature:

1.Capping head: Automatic cover and automatic cap. We can choose different capping heads for different sizes of bottles. Different bottles have different fittings and are easy to replace.

2.Cap feeder: We can choose different cap feeder according to your cap, one is lifter, one is vibration plate.

3.Turntable capping machine is suitable for pharmaceutical, daily chemical and other industries.

4.High-precision cam indexer can locate the star-dividing disk with no gap and accurate positioning.

5.Touch screen, PLC intelligent control, simple operation, convenient man-machine dialogue.

6.It has the functions of no bottle no feeding cap and no bottle no screwing cap.

7.The machine is controlled by air and electricity. The working surface is protected by stainless steel. The whole machine meets the requirements of GMP.

8.The machine adopts mechanical transmission, transmission accuracy, smooth, with low loss, smooth work, stable output and other advantages, especially suitable for batch production.

9.It adopts Frequency controlled drive, and transportation exit is adjustable, so it could meet different packaging machinery pipeline request.

Introduction:

This automatic rotary plate capping machine is our new designed product recently. It adopts rotary plate to positioning the bottle and capping. The type machine is widely used in packaging cosmetic, chemical, foods, pharmaceutical, pesticides industry and so on. Besides plastic cap, it is workable for the metal caps as well.

Process:

Bottle in → Feeding cap → Put the cap on the bottle → Capping →Bottle out

Feature:

1.Capping head: Automatic cover and automatic cap. We can choose different capping heads for different sizes of bottles. Different bottles have different fittings and are easy to replace.

2.Cap feeder: We can choose different cap feeder according to your cap, one is lifter, one is vibration plate.

3.Turntable capping machine is suitable for pharmaceutical, daily chemical and other industries.

4.High-precision cam indexer can locate the star-dividing disk with no gap and accurate positioning.

5.Touch screen, PLC intelligent control, simple operation, convenient man-machine dialogue.

6.It has the functions of no bottle no feeding cap and no bottle no screwing cap.

7.The machine is controlled by air and electricity. The working surface is protected by stainless steel. The whole machine meets the requirements of GMP.

8.The machine adopts mechanical transmission, transmission accuracy, smooth, with low loss, smooth work, stable output and other advantages, especially suitable for batch production.

9.It adopts Frequency controlled drive, and transportation exit is adjustable, so it could meet different packaging machinery pipeline request.

Machine name | LQ-ZP-400 Bottle Capping Machine |

Speed | About 30 bottles/min (depend on product size) |

Qualified rate | ≥98% |

Power supply | 220V,50Hz,1Ph,1.5kW |

Air source | 0.4kg/cm2,10m3/h |

Machine size | L*W*H: 2500mm × 2000mm × 2000mm |

Weight | 450kg |

Machine name | LQ-ZP-400 Bottle Capping Machine |

Speed | About 30 bottles/min (depend on product size) |

Qualified rate | ≥98% |

Power supply | 220V,50Hz,1Ph,1.5kW |

Air source | 0.4kg/cm2,10m3/h |

Machine size | L*W*H: 2500mm × 2000mm × 2000mm |

Weight | 450kg |