- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

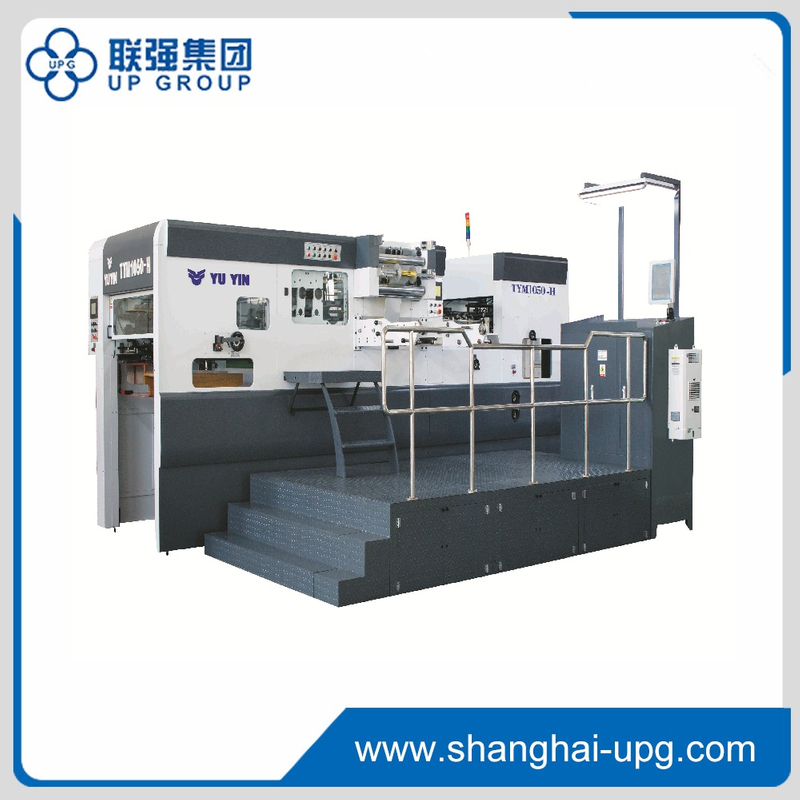

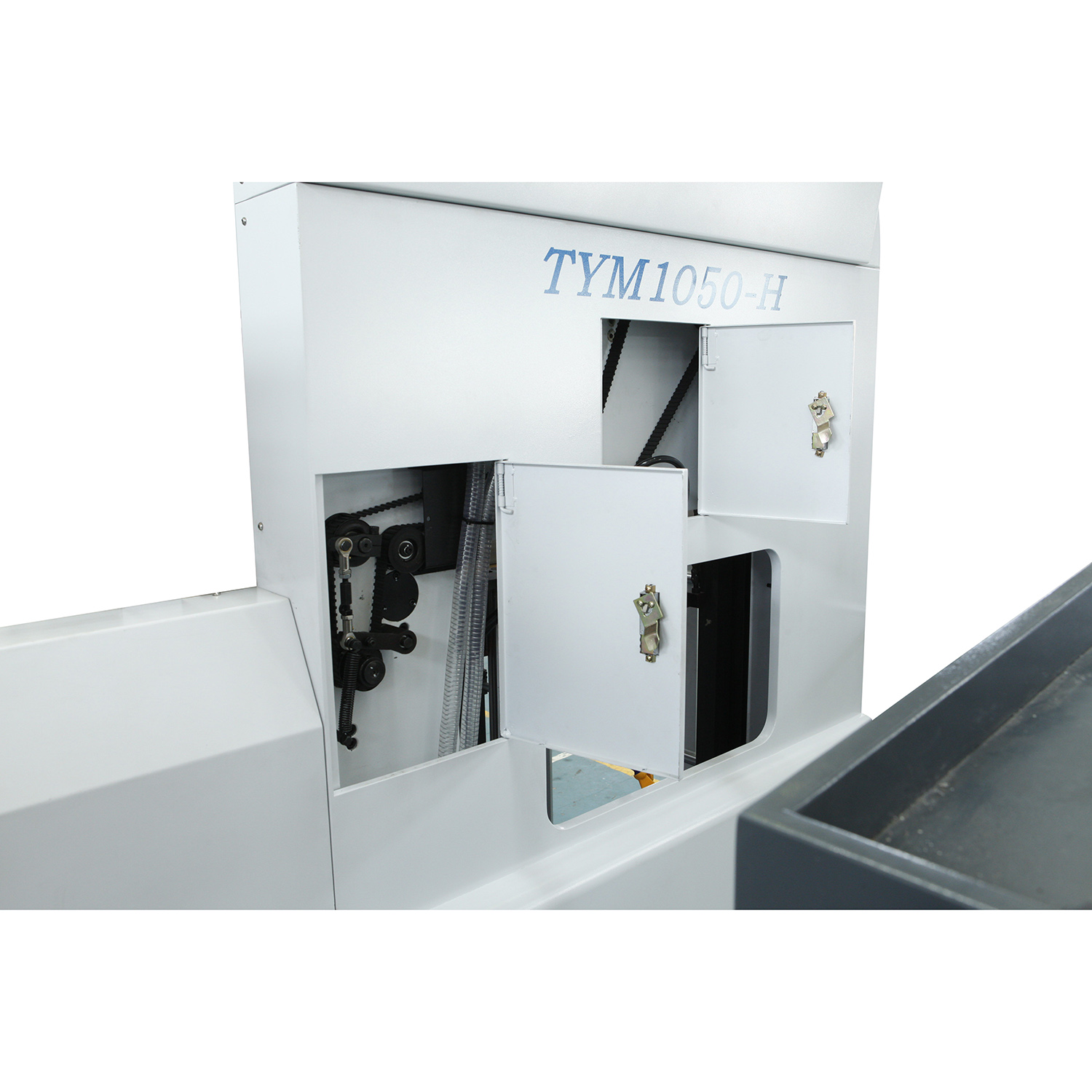

TYM1050-H

UPG

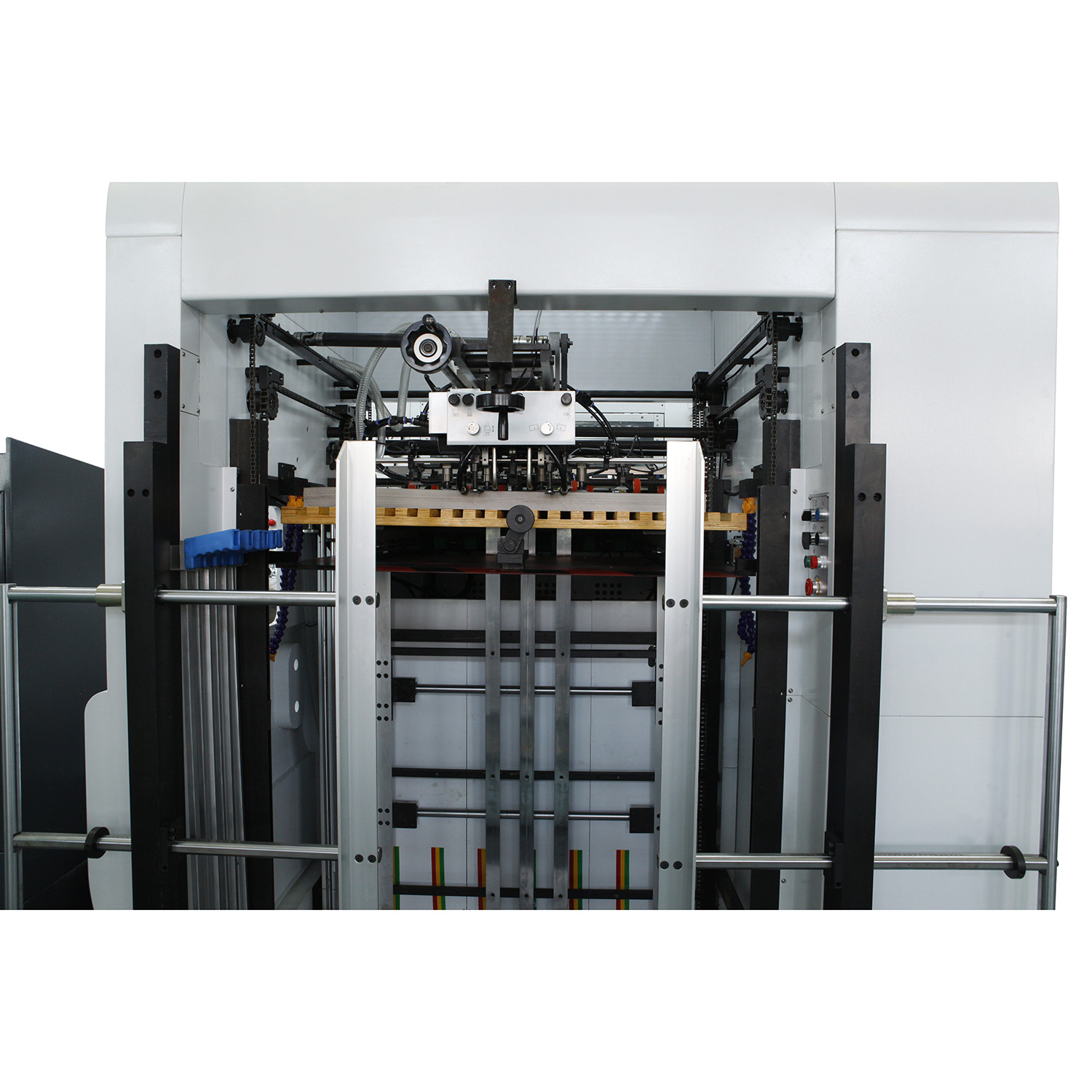

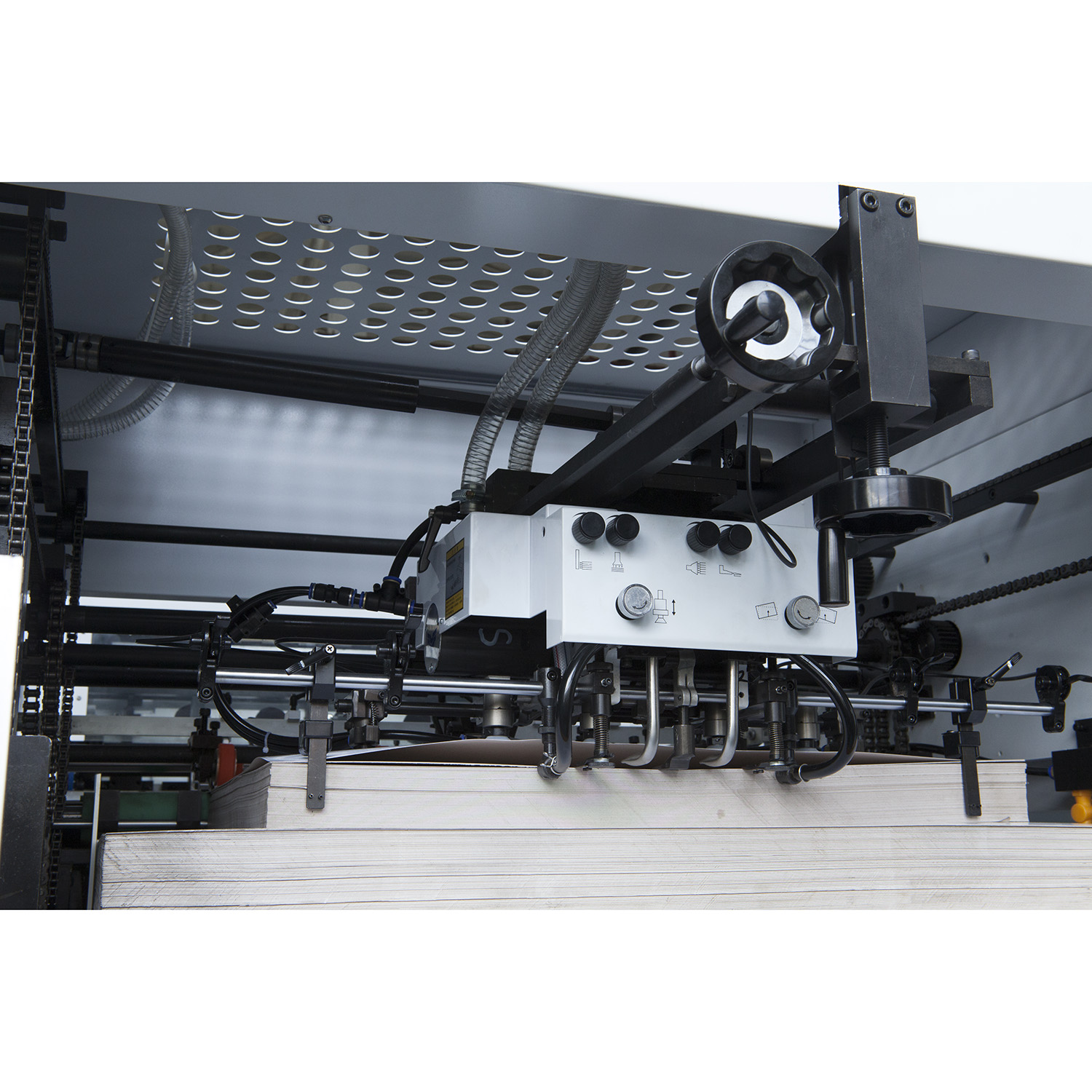

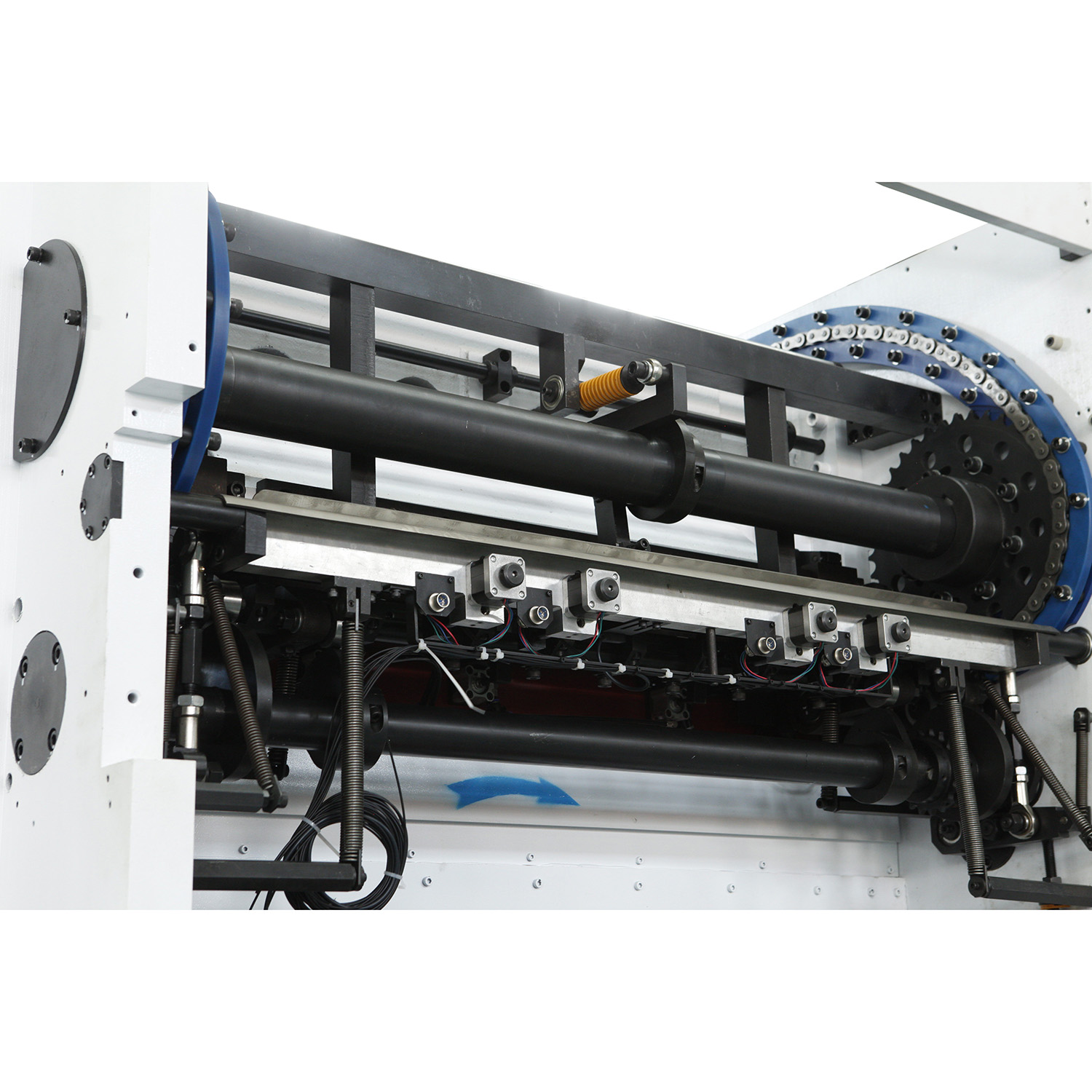

Q:How to ensure the accuracy of stamping of TYM1050H? A:It has four sets of servo motors,which can control the foil roll in and out of the machine respectively , so as to make the foil roll in and out synchronous and consistent,and ensure the stamping accuracy. Q:How about the safety and stability of the TYM1050H ? A:Its main drive uses a large pitch chain ,which can reduce the rotation inertia and improve the stability of accuracy; the torque controller is installed to improve the safety protection. Q:How about the production efficiency of TMY1050H? A:It uses manual foil stringing device to improve working efficiency.Its highest die cutting speed is 6500s / h.Its highest stamping speed is 5000S / h. | |

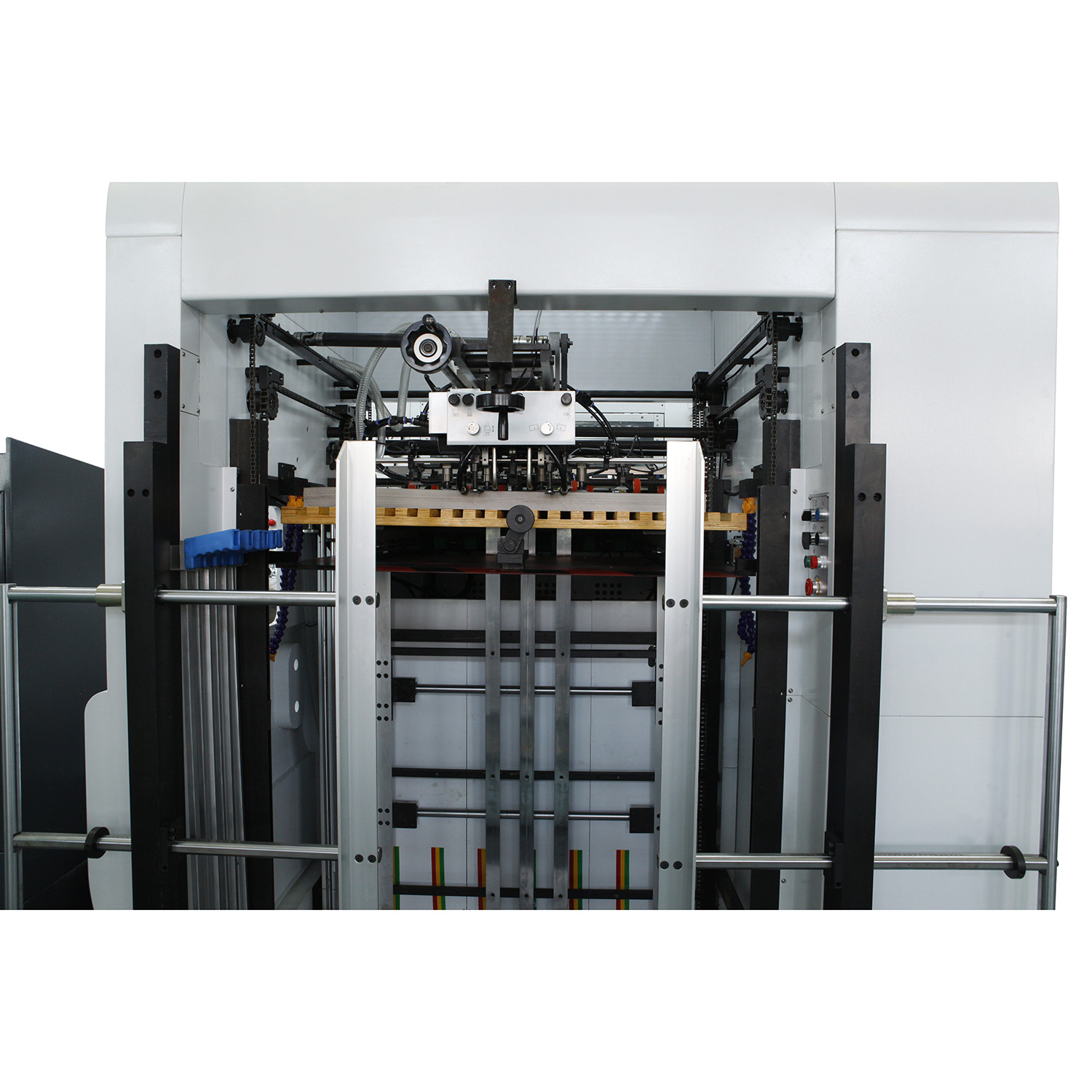

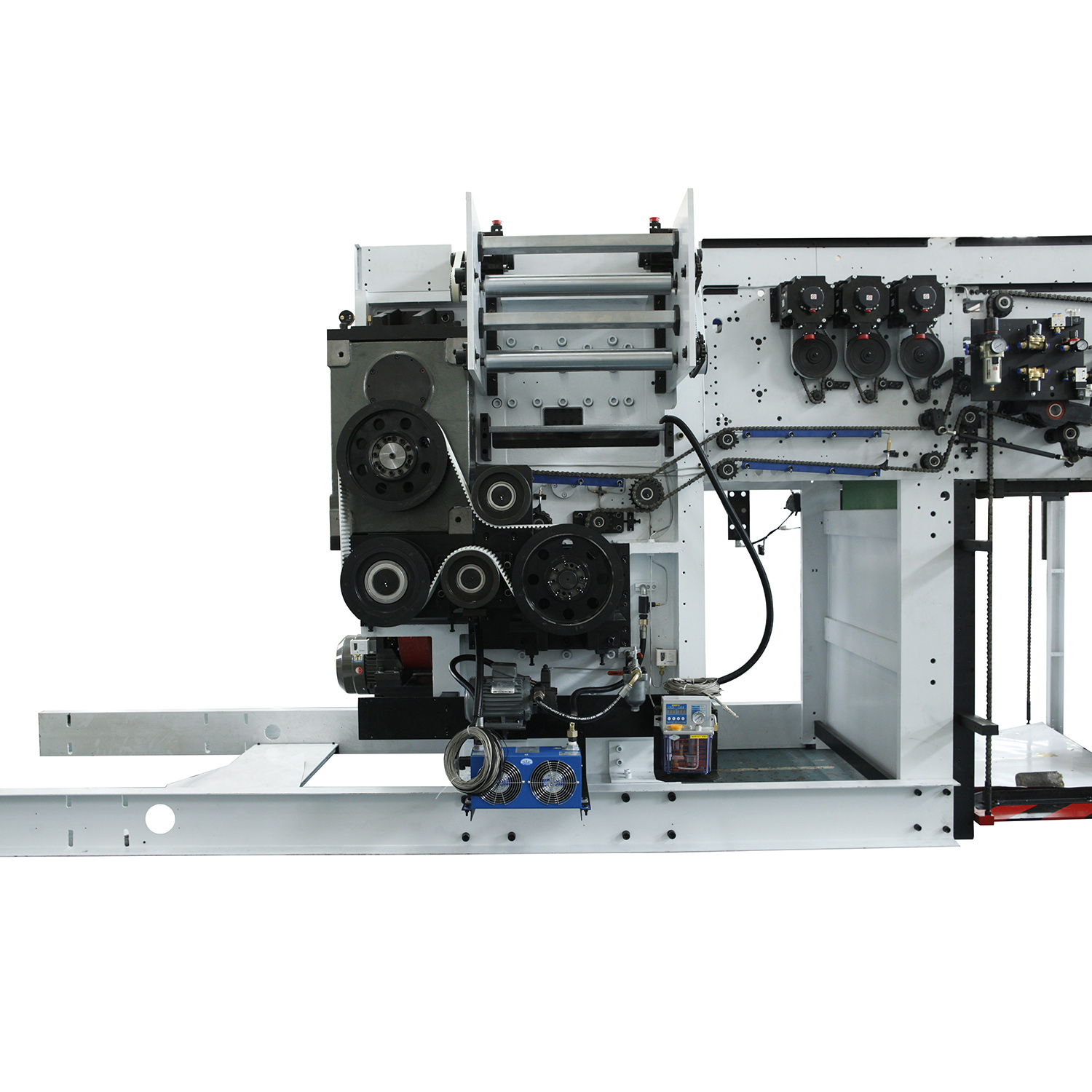

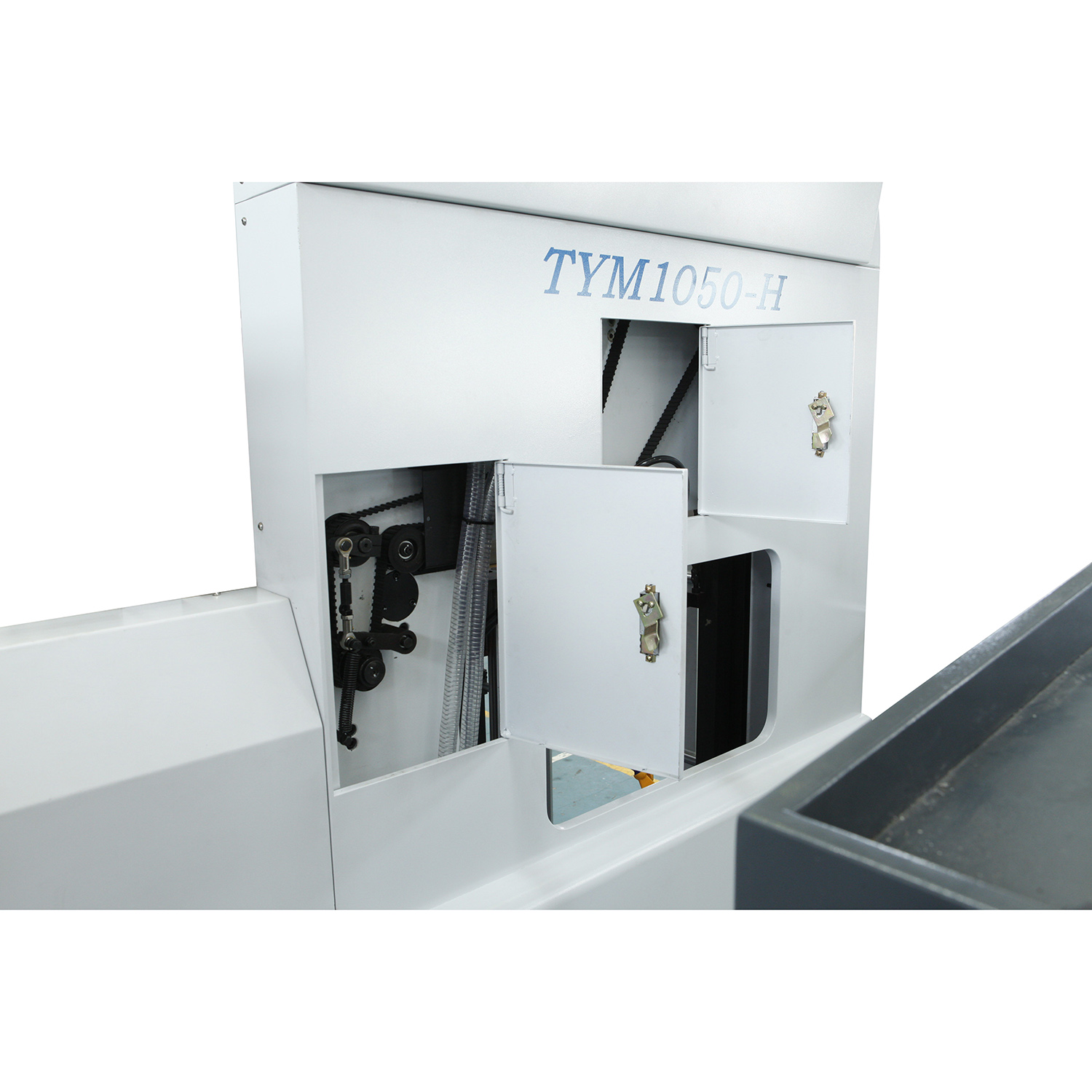

TYM1050-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. This kind of machine is a new generation of foil stamping series on the basis of TYM1020-H, it’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliablity, high speed, press and precision. | |

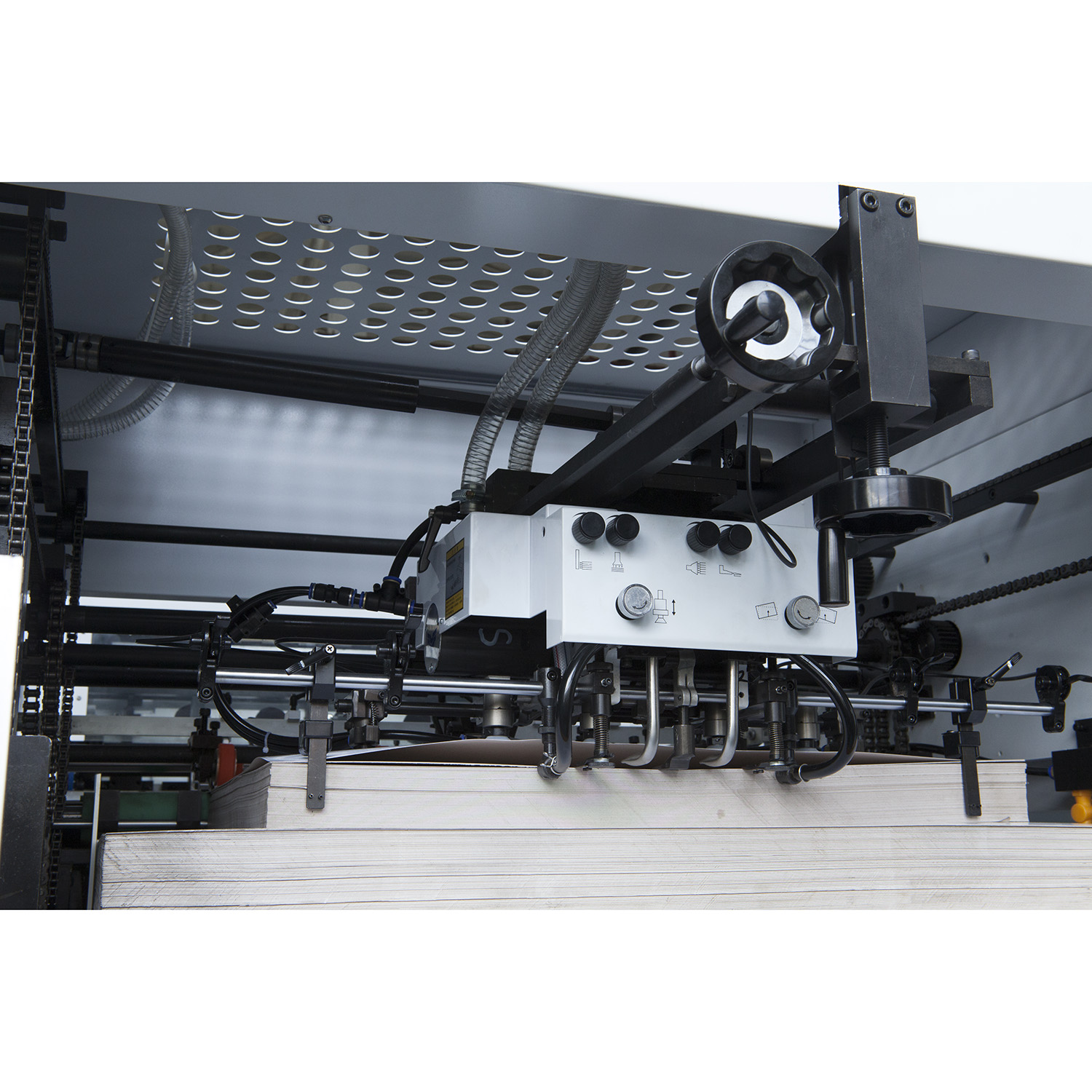

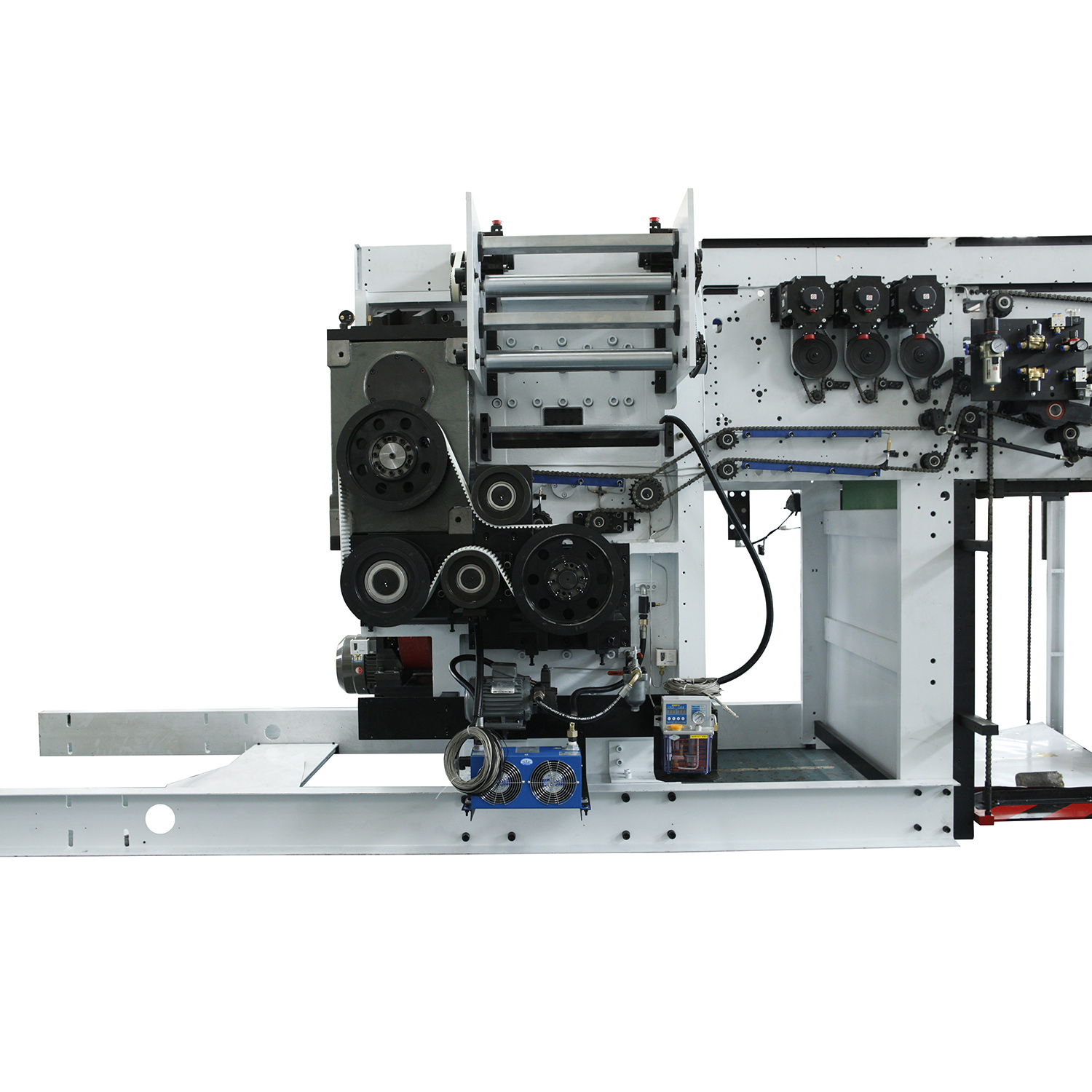

● Cooling device for lubricating oil is added which reduces the wear of parts when they are heated, ensures the constant pressure of diecutting and foil stamping. Air blow and gripper barBecker pumpDouble sheet deviceclutchClutch and main motorelectrical cabinet |

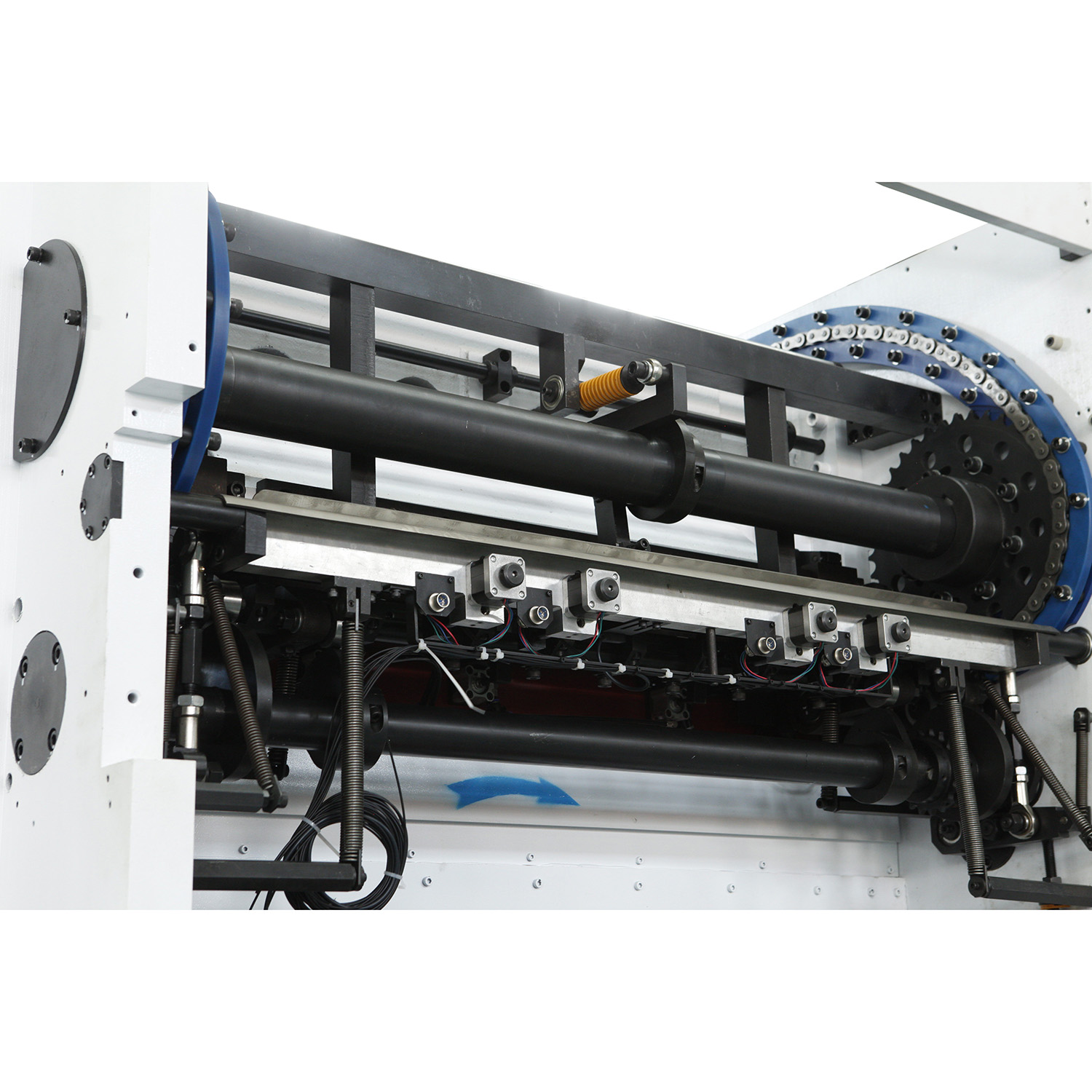

Feeder |  Feeder |  servo controller |

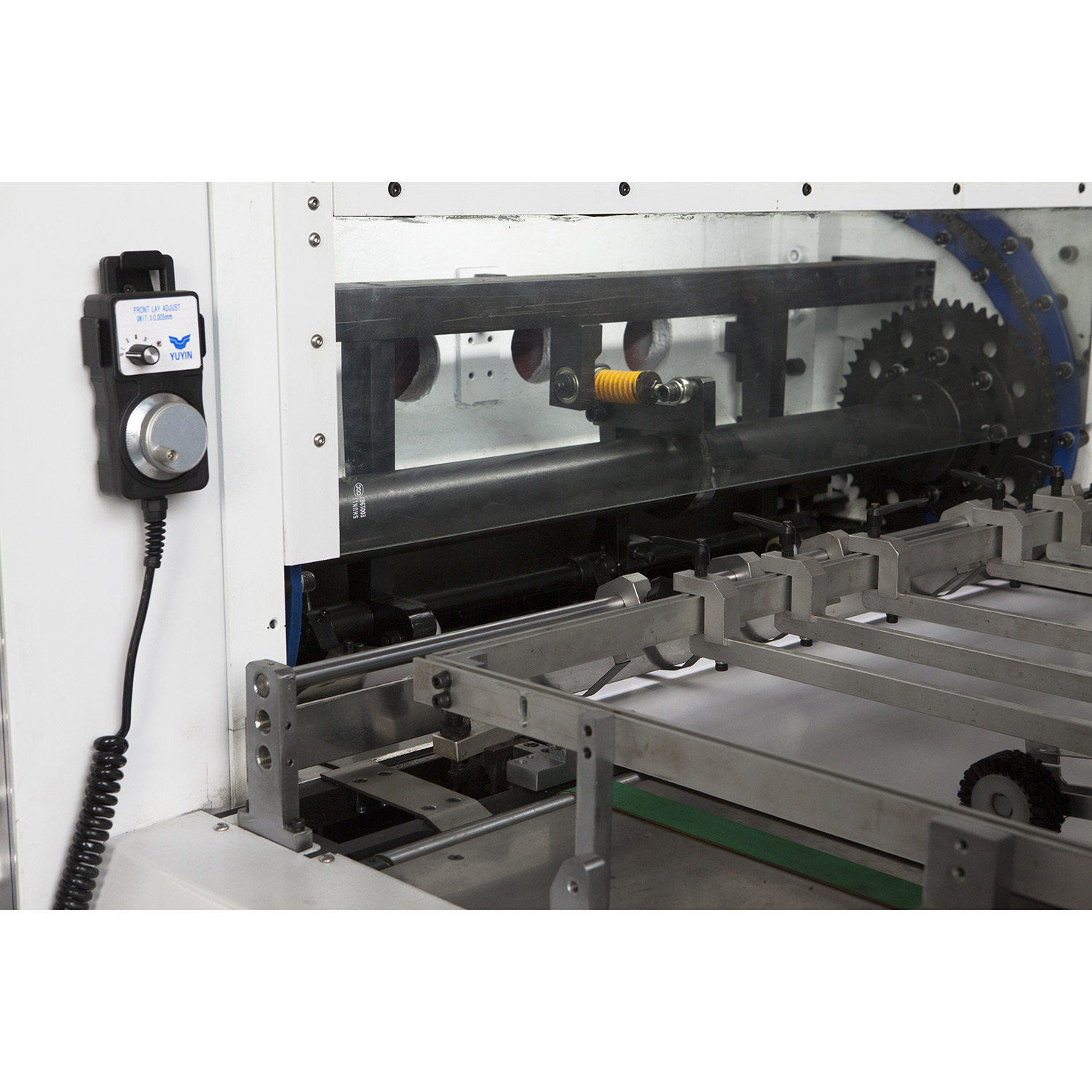

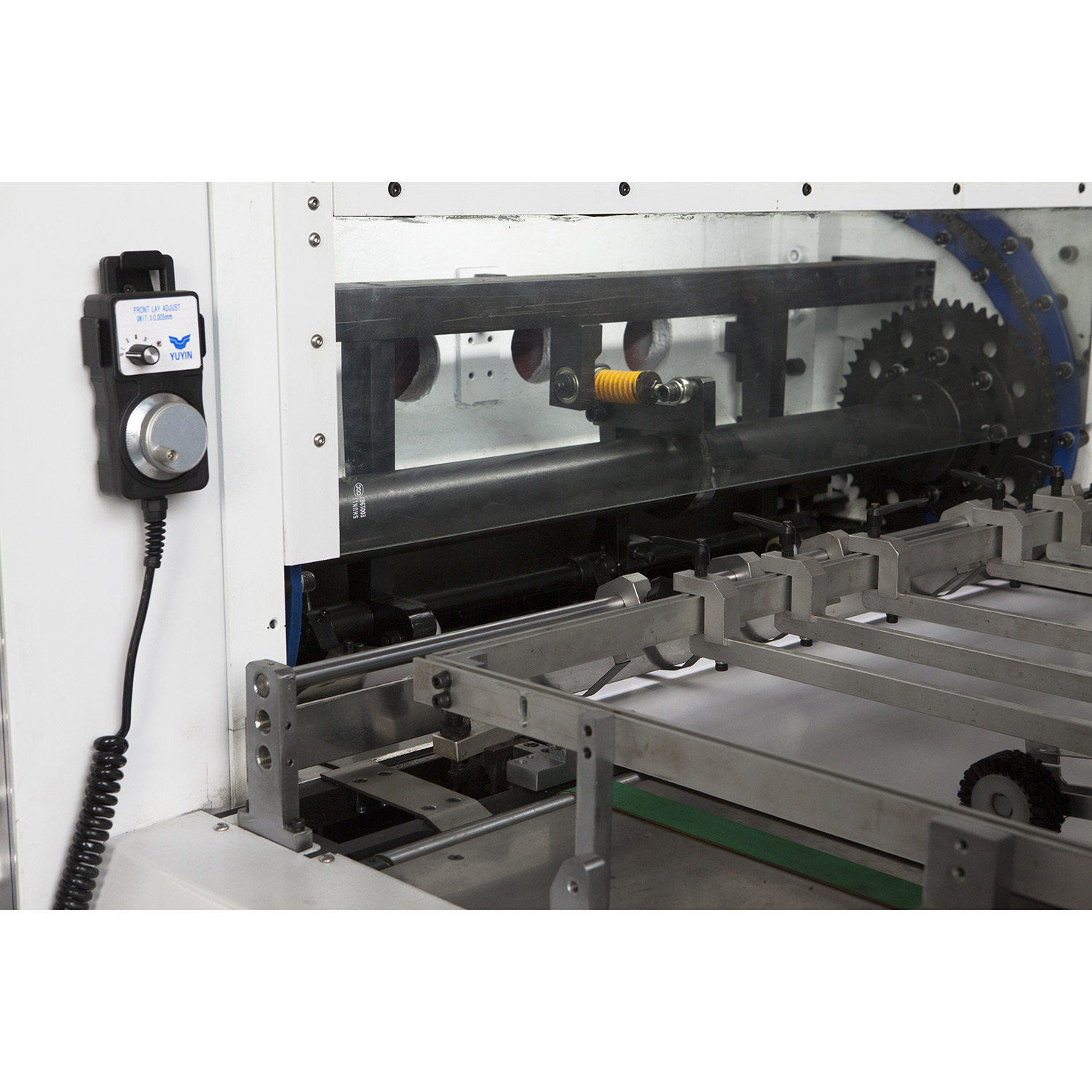

Front lay |  Front lay and side lay handle wheel control |  intermittent mechanism |

Servo motor |  Timing belt transfer |  Worm shaft |

Q:How to ensure the accuracy of stamping of TYM1050H? A:It has four sets of servo motors,which can control the foil roll in and out of the machine respectively , so as to make the foil roll in and out synchronous and consistent,and ensure the stamping accuracy. Q:How about the safety and stability of the TYM1050H ? A:Its main drive uses a large pitch chain ,which can reduce the rotation inertia and improve the stability of accuracy; the torque controller is installed to improve the safety protection. Q:How about the production efficiency of TMY1050H? A:It uses manual foil stringing device to improve working efficiency.Its highest die cutting speed is 6500s / h.Its highest stamping speed is 5000S / h. | |

TYM1050-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. This kind of machine is a new generation of foil stamping series on the basis of TYM1020-H, it’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliablity, high speed, press and precision. | |

● Cooling device for lubricating oil is added which reduces the wear of parts when they are heated, ensures the constant pressure of diecutting and foil stamping. Air blow and gripper barBecker pumpDouble sheet deviceclutchClutch and main motorelectrical cabinet |

Feeder |  Feeder |  servo controller |

Front lay |  Front lay and side lay handle wheel control |  intermittent mechanism |

Servo motor |  Timing belt transfer |  Worm shaft |

| Max. Sheet Size | 1060 x760mm |

| Min. Sheet Size | 450 X 370mm |

| Max. Die-Cutting Size | 1050 x750mm |

| Max. Foil Stamping Size | Longitudinal:1040x730mm Lateral:1040x640mm |

| Max. Die-Cutting Speed | 6500s/h |

| Max. Stamping Speed | 6000s/h |

| Max. Pressure | 300T |

| Max. Foil Diameter | Φ195mm/3" Φ100mm/1" |

| Max. Feeding Pile | 1400mm |

| Max. Delivery Pile | 1150mm |

| Sheet Thickness | Corrugated Paper ≤ 4mm Cardboard 0.1-1 .5mm |

| Net Weight | 20T |

| Total Power | 46.5kw |

| Quantity Of Heating Area | 12 |

| Die-cutting Precision | ±0.1mm |

| Overall Dimension | 5918X4780X2383mm |

| Max. Sheet Size | 1060 x760mm |

| Min. Sheet Size | 450 X 370mm |

| Max. Die-Cutting Size | 1050 x750mm |

| Max. Foil Stamping Size | Longitudinal:1040x730mm Lateral:1040x640mm |

| Max. Die-Cutting Speed | 6500s/h |

| Max. Stamping Speed | 6000s/h |

| Max. Pressure | 300T |

| Max. Foil Diameter | Φ195mm/3" Φ100mm/1" |

| Max. Feeding Pile | 1400mm |

| Max. Delivery Pile | 1150mm |

| Sheet Thickness | Corrugated Paper ≤ 4mm Cardboard 0.1-1 .5mm |

| Net Weight | 20T |

| Total Power | 46.5kw |

| Quantity Of Heating Area | 12 |

| Die-cutting Precision | ±0.1mm |

| Overall Dimension | 5918X4780X2383mm |

TYM1050-H Automatic Foil Stamping & Die-Cutting Machine

TYM1050-H Automatic Foil Stamping & Die-Cutting Machine