- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD FC20

UPG

Features & Advantages

Unwinding/Rewinding unit

Constant-tension unwinding and rewinding unit could control tension ranging from 1-10N whose tolerance is ±5N. Meanwhile it has independent servo motor to control to alarm protection when the material is disconnected.

Deviation System

This system adopt higher-precision rectify system and also use supersonic wave to monitor timely so as to correct them when the thing are under transportation, whose correction precision is ±0.5mm.

Anti-static device

It exists one set of anti-static elimination unit behind the detection station to eliminate materials' static under production after material come into different bonding team or heating pressure, which could guarantee chips and material not to be damaged by static.

Chip-Paste unit

Composite structure adopts anti-static, anti-adhesive, anti-pressure roller and fine-metal roller to ensure the productions not to be damaged and to run stably. The paste precision is around ±0.035mm.

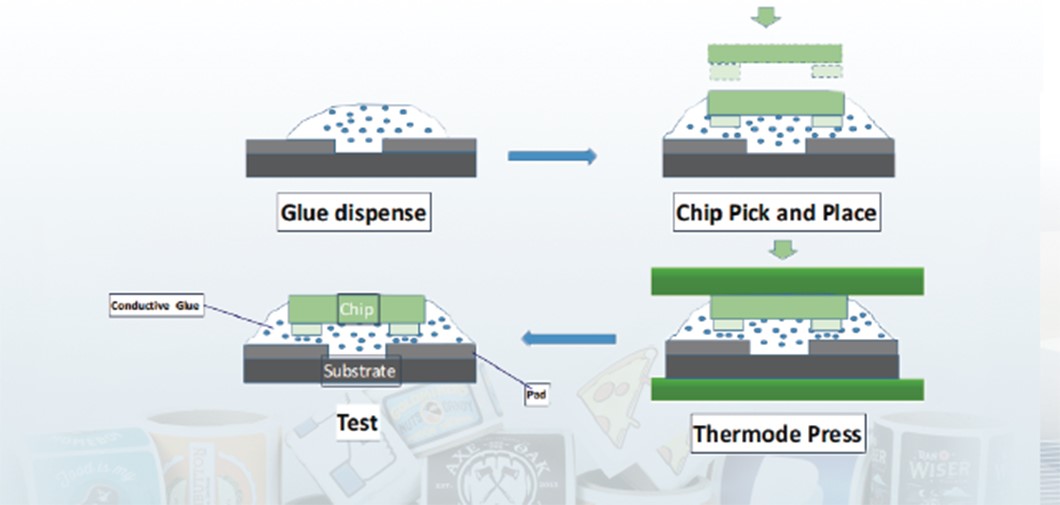

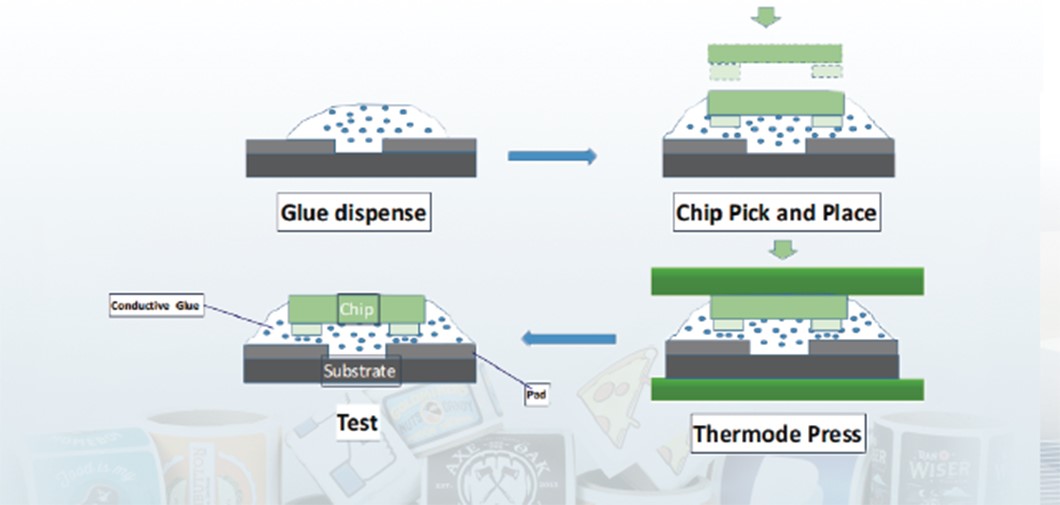

Technological Process

Product Parameter

| Modle | LQ-MD FC20 |

| Speed | 15000-20000pcs/h |

| The width of material | 20-180mm |

| The application material | PET paper |

| The paste precision | ±0.035mm (≤2 degree) |

| The antenna jump distance | min 15mm |

| The yield | ≈99.7% |

| Heating head | 60 |

| Gas consumption | 300L/min |

| Control | PC + Servo |

| Power | AC380V;50/60Hz; 40A; 16kw |

| Air pressure | 6kg/cm2 |

| The max roll diameter | 600mm |

| Overal size | 6500*1300*1800mm |

| Weight | 3000kg |

Features & Advantages

Unwinding/Rewinding unit

Constant-tension unwinding and rewinding unit could control tension ranging from 1-10N whose tolerance is ±5N. Meanwhile it has independent servo motor to control to alarm protection when the material is disconnected.

Deviation System

This system adopt higher-precision rectify system and also use supersonic wave to monitor timely so as to correct them when the thing are under transportation, whose correction precision is ±0.5mm.

Anti-static device

It exists one set of anti-static elimination unit behind the detection station to eliminate materials' static under production after material come into different bonding team or heating pressure, which could guarantee chips and material not to be damaged by static.

Chip-Paste unit

Composite structure adopts anti-static, anti-adhesive, anti-pressure roller and fine-metal roller to ensure the productions not to be damaged and to run stably. The paste precision is around ±0.035mm.

Technological Process

Product Parameter

| Modle | LQ-MD FC20 |

| Speed | 15000-20000pcs/h |

| The width of material | 20-180mm |

| The application material | PET paper |

| The paste precision | ±0.035mm (≤2 degree) |

| The antenna jump distance | min 15mm |

| The yield | ≈99.7% |

| Heating head | 60 |

| Gas consumption | 300L/min |

| Control | PC + Servo |

| Power | AC380V;50/60Hz; 40A; 16kw |

| Air pressure | 6kg/cm2 |

| The max roll diameter | 600mm |

| Overal size | 6500*1300*1800mm |

| Weight | 3000kg |