Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

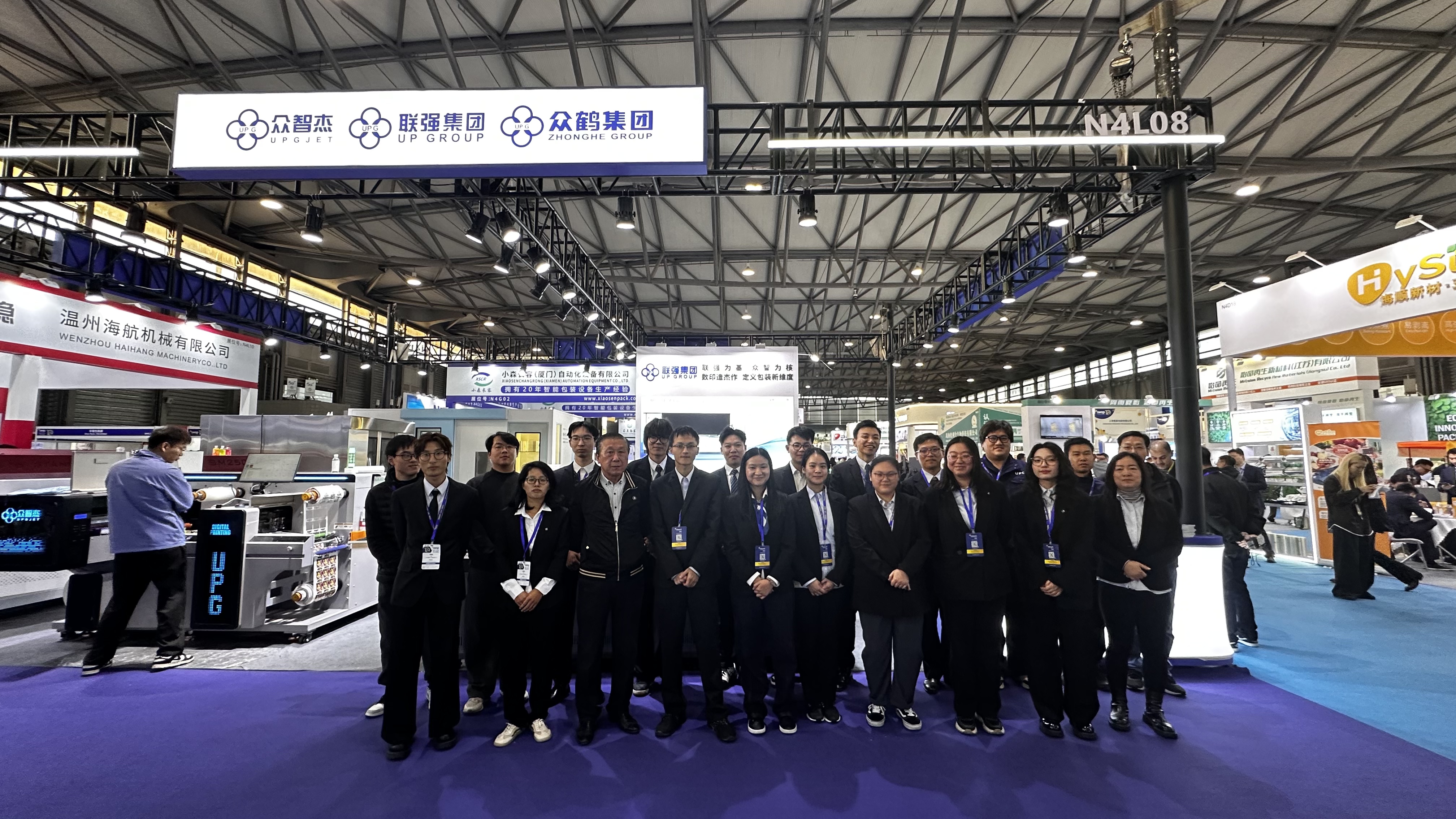

Shanghai, 25-27 November 2025.The three-day SWOP Shanghai 2025 International Packaging and Printing Exhibition concluded successfully on 27 November at the Shanghai New International Expo Centre (SNIEC). At this industry gathering, our company made a striking appearance with a diverse range of equipment spanning three key sectors: digital printing, purification systems, and complementary intelligent auxiliary devices. Our product portfolio, characterized by ‘technological comprehensiveness and universal application across scenarios,’ captured the attention of international visitors, establishing us as one of the exhibition's focal points.

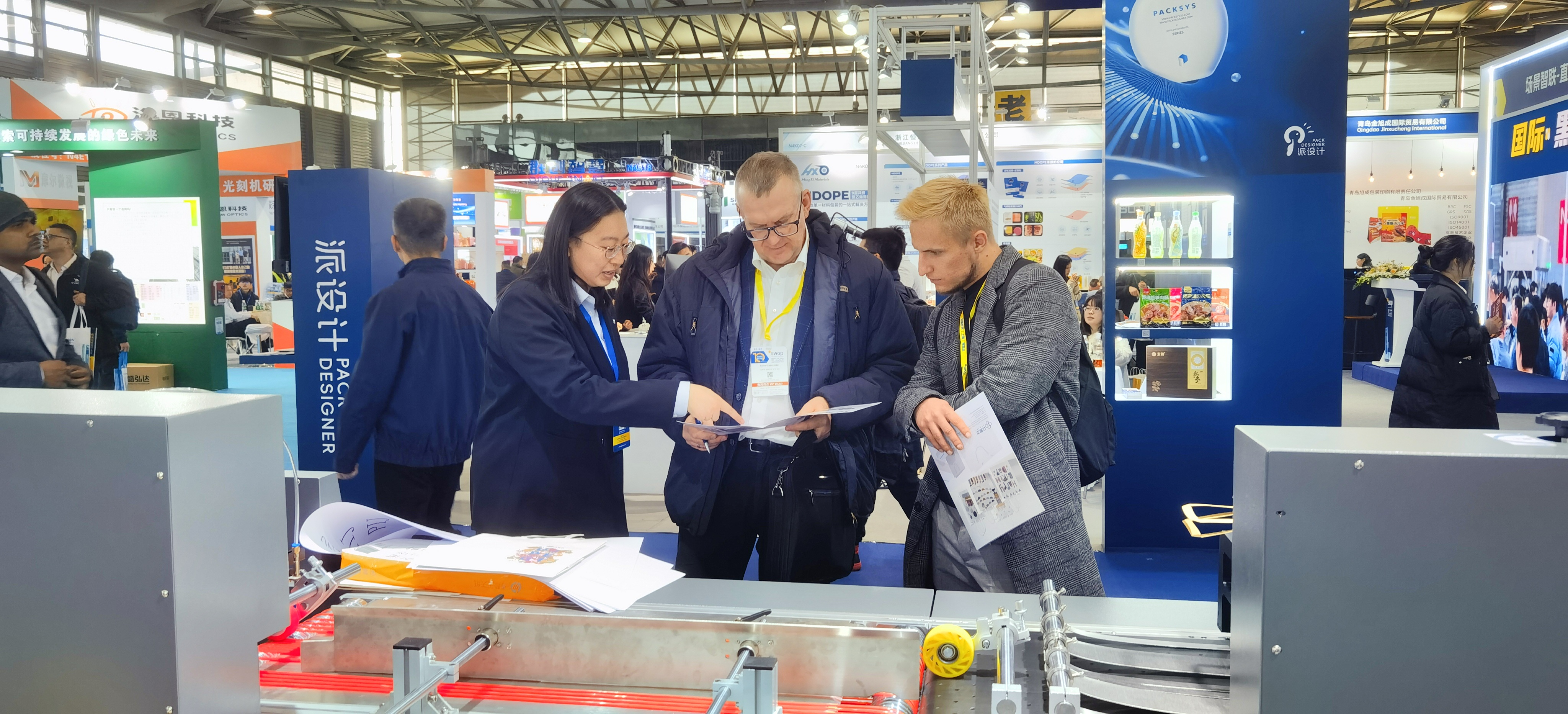

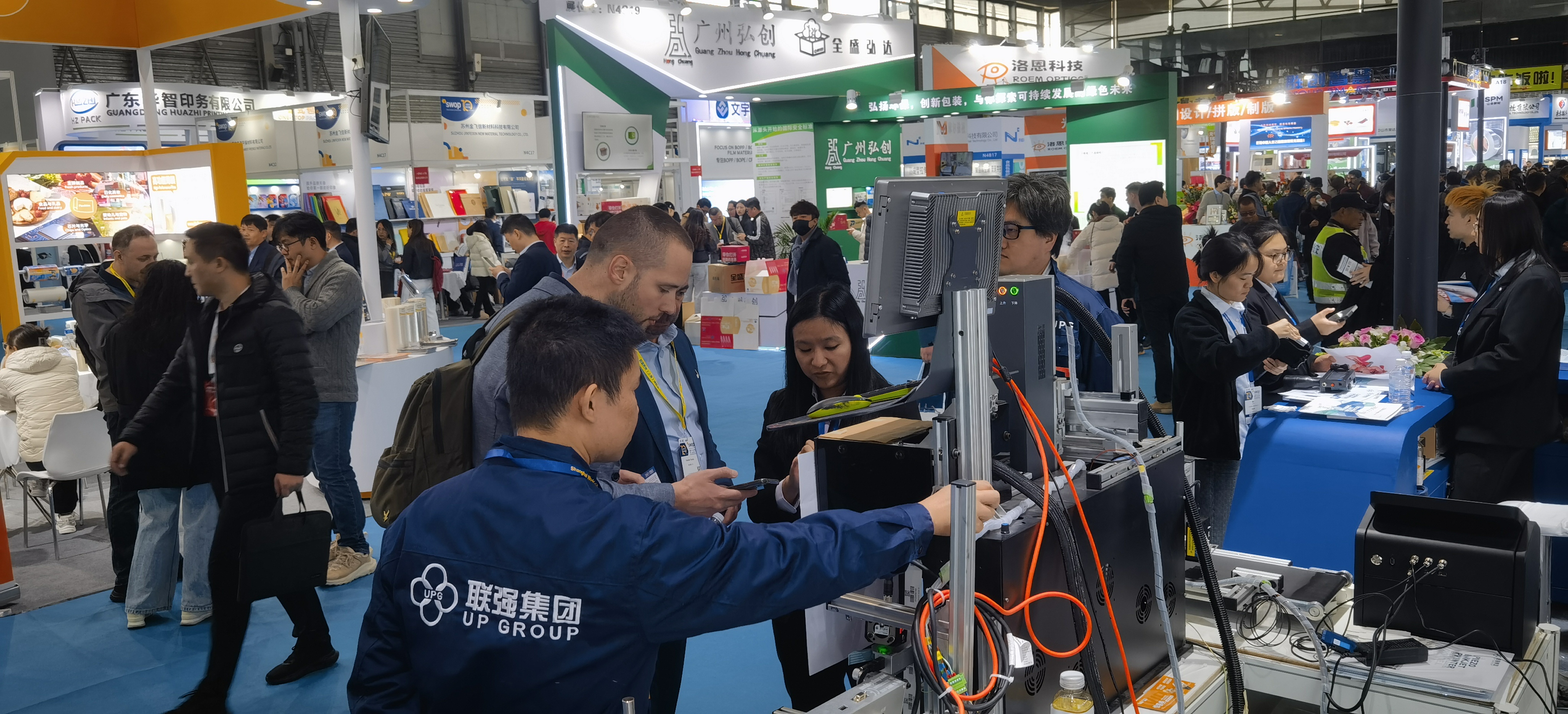

As the mainstay of the product portfolio, three flagship digital printing devices leverage their distinct technological advantages to precisely meet the production demands of diverse industries. The live demonstrations drew sustained crowds throughout the event:

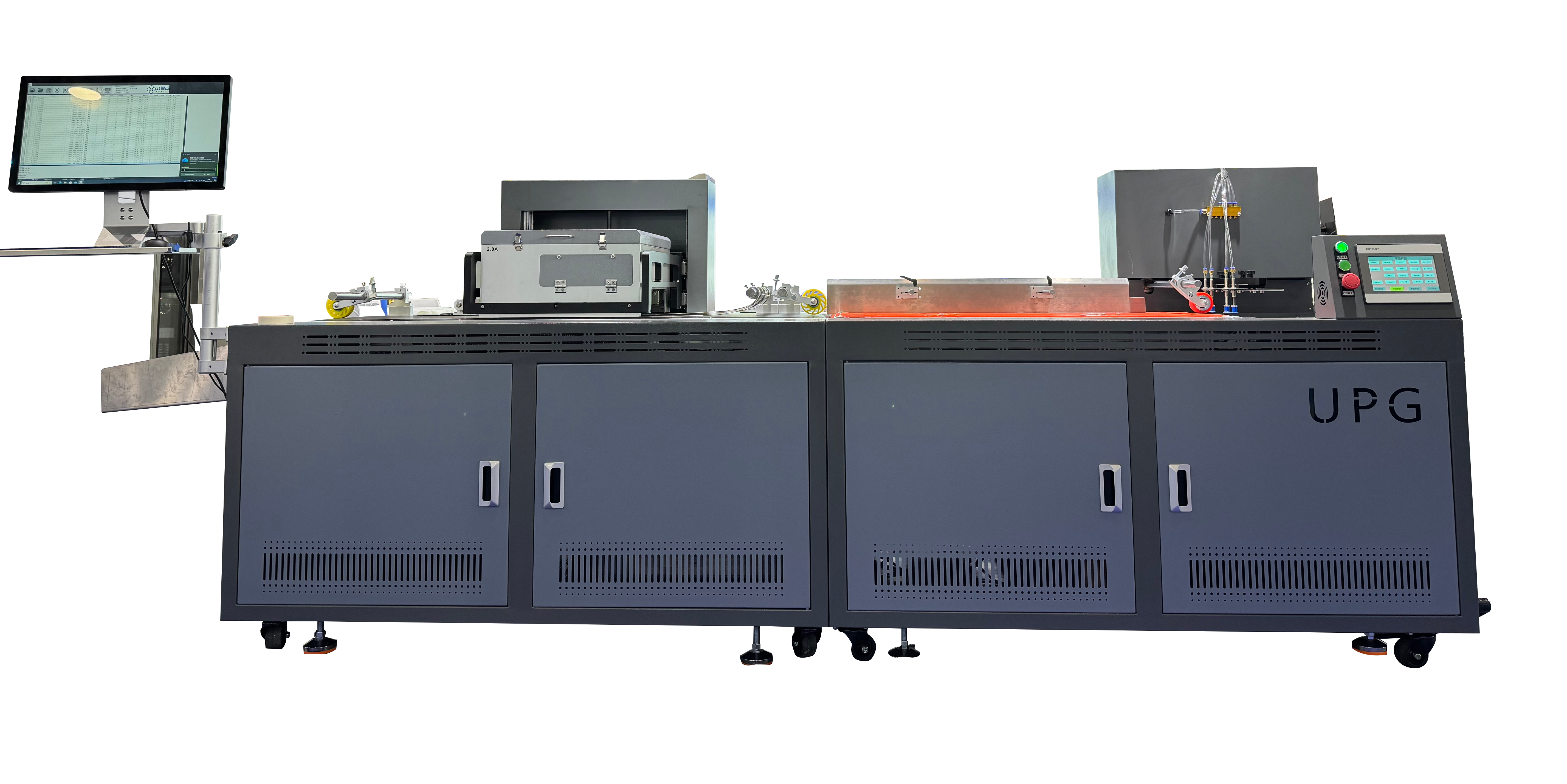

1. LQ-MD UV330 Multi-Pass Printer: Multi-functional integration delivering both efficiency and quality

This equipment centers on ‘one-stop processing’ as its core feature, achieving high integration of multiple functions including printing, laminating/foil stamping, die-cutting, and slitting. It enables end-to-end processing without frequent equipment changes. Its printing precision reaches industry-leading standards with high colour fidelity, making it particularly suitable for scenarios demanding complex craftsmanship such as packaging gift boxes and premium labels. This solution helps enterprises reduce production cycle times by over 30%.

2. LQ-MD 297 Paper Bag Sheet-fed Printer: Precision Positioning, Plate-less Printing Leading the Eco-Friendly Trend

Tailored to the specialized demands of paper bag printing, the LQ-MD 297 sheet-fed printer ensures pinpoint print positioning through the seamless integration of high-precision conveyor belts and encoders, effectively eliminating the misalignment issues common in traditional printing. Notably, this equipment employs ‘plate-less printing’ technology, which not only reduces plate production costs for enterprises but also minimises material wastage during plate manufacturing. This aligns with the current industry trend towards green printing, providing robust support for environmentally conscious production models.

3. LQ-MD 215DT Digital Labelling Machine: Bubble-Free Labelling, Multi-Industry Applicability

Within the labelling equipment sector, the LQ-MD 215DT digital labelling machine delivers equally impressive performance. The equipment innovatively adopts a belt-driven design, fundamentally resolving the industry-wide challenge of bubble formation during traditional labelling processes to ensure a smooth and aesthetically pleasing finish. Its extensive applicability spans sectors demanding exceptional labelling precision—including pharmaceuticals, chemicals, and foodstuffs—delivering bespoke labelling solutions for diverse industry clients.

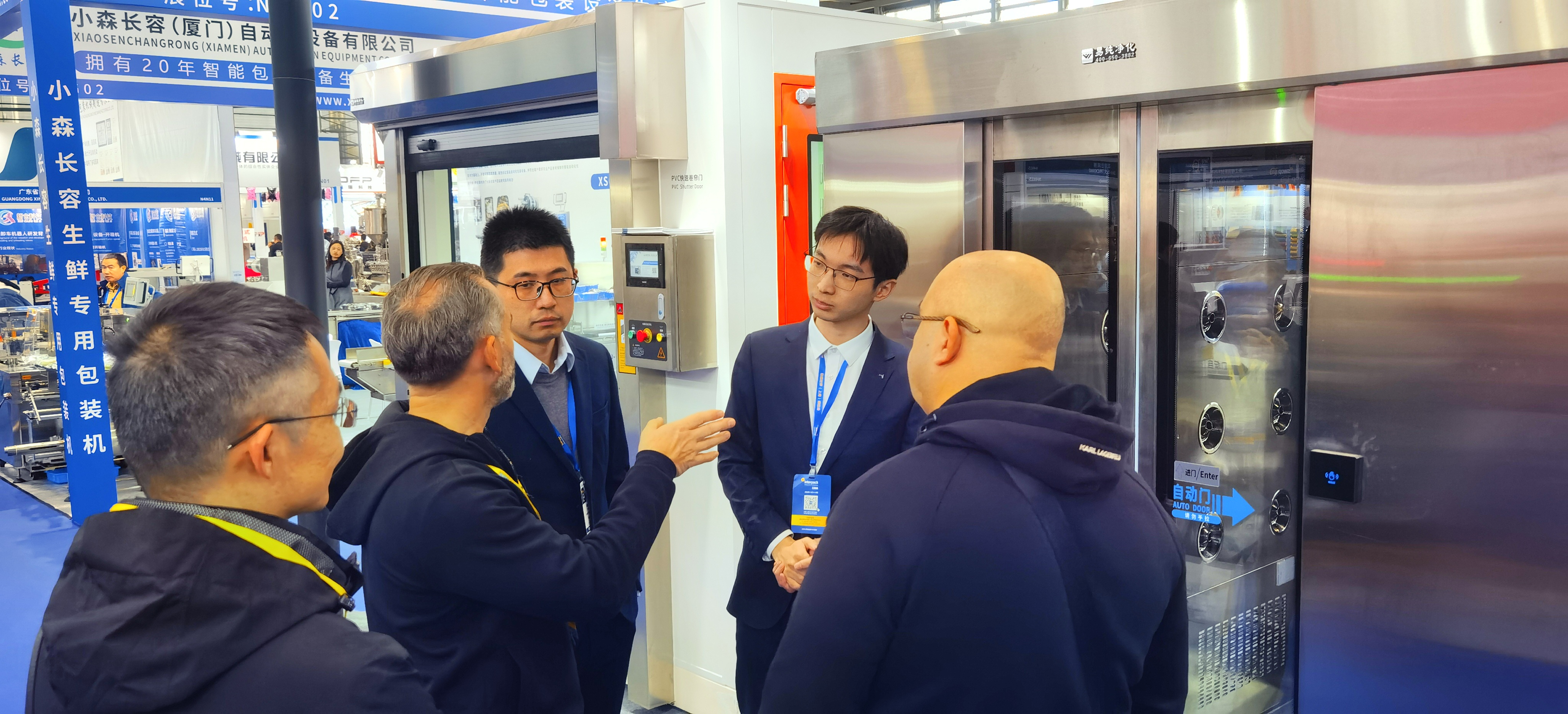

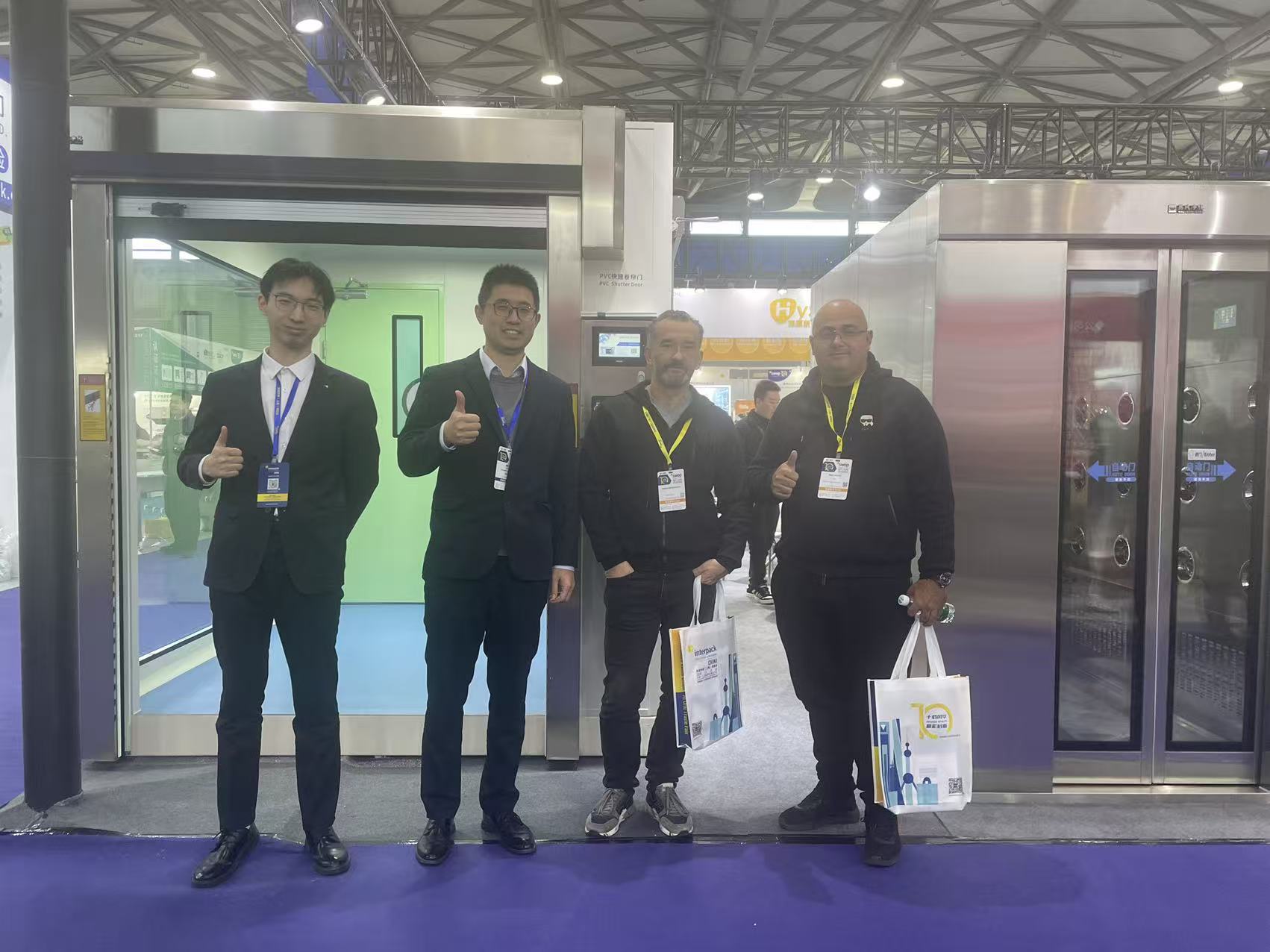

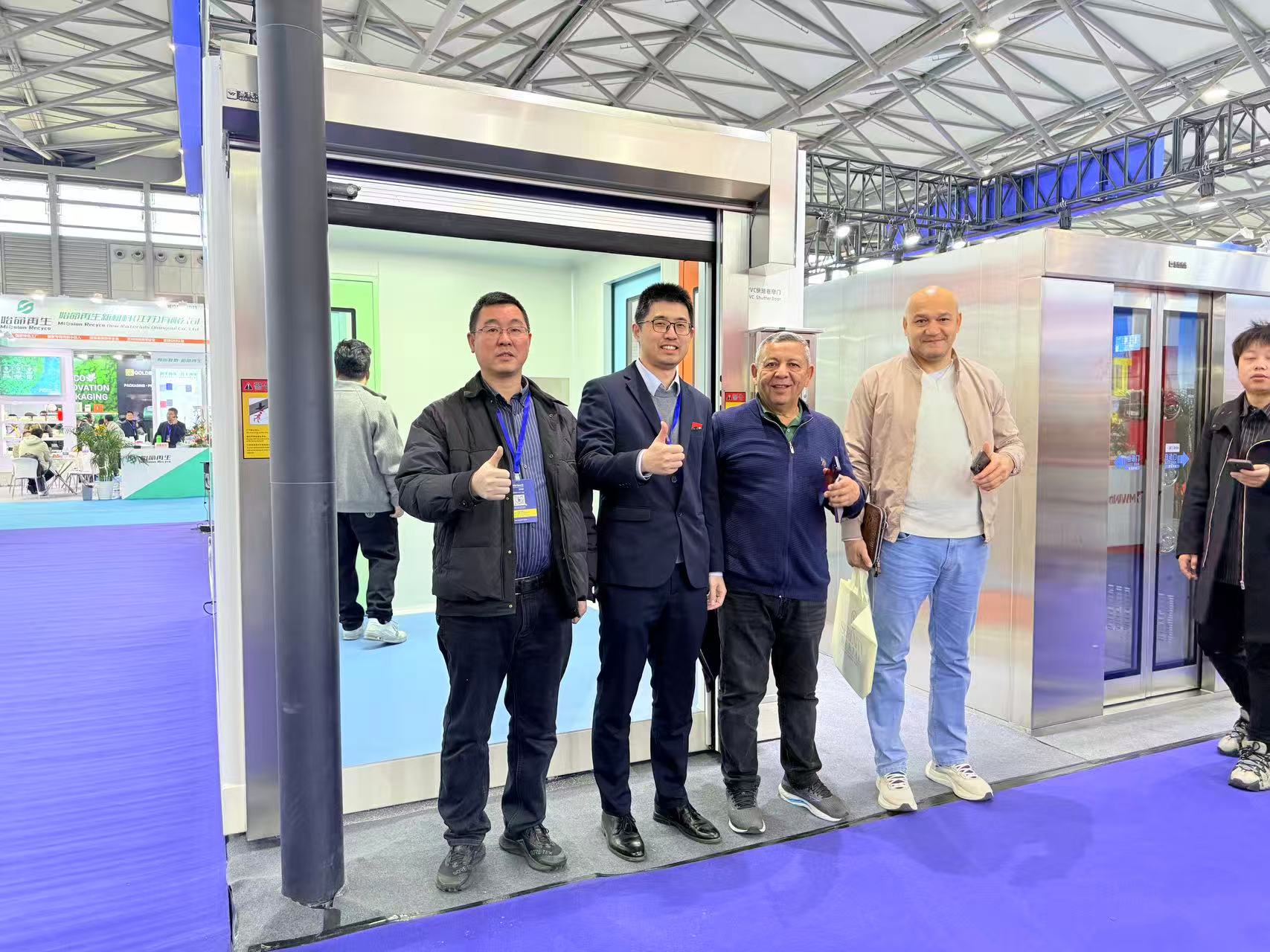

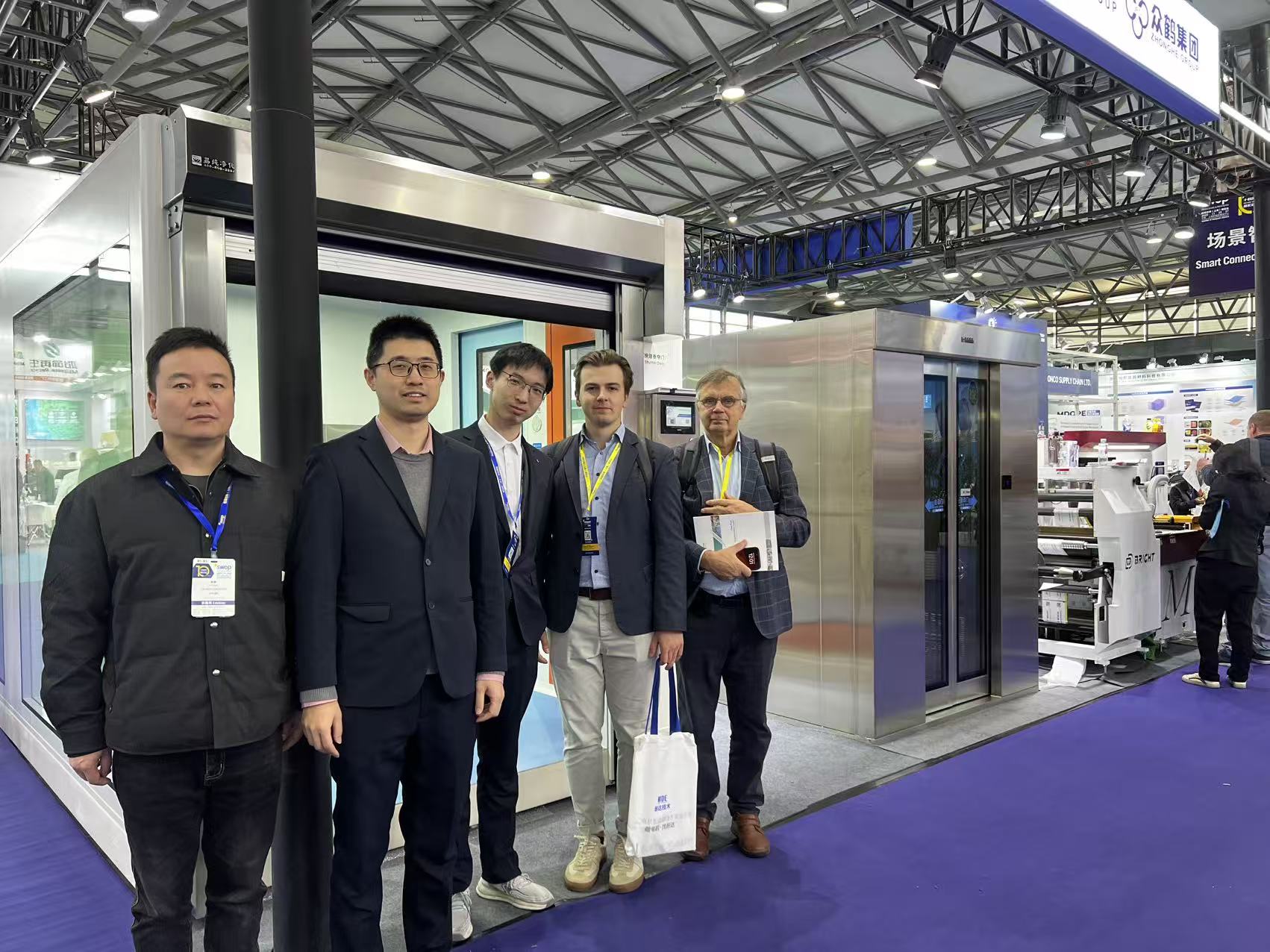

Alongside printing equipment, the exhibition simultaneously showcased purification products offering ‘production environment solutions’ for high-standard industries such as food and pharmaceuticals, Become a standout feature in on-site competitive differentiation.

1. Air Shower: High-Efficiency Purification + Excellent Value for Money

Featuring a dual-fan multi-angle airflow design, this unit achieves 99% purification efficiency, effectively removing dust and contaminants from personnel and goods surfaces. Balancing meticulous craftsmanship with competitive pricing, on-site clients have remarked on its ‘robust construction and low operational noise’. Several food enterprises have expressed procurement interest, laying the groundwork for future project collaborations.

2. Cleanroom Demonstration Facility: Visually Demonstrating Professional Expertise

The demonstration facility replicates the core structure of a cleanroom at a 1:1 scale, visually illustrating principles such as air filtration, airflow organisation, and differential pressure control through clear design. Within a limited footprint, it comprehensively showcases the entire process from primary filtration to high-efficiency purification, enabling clients to intuitively grasp the technical logic of cleanroom operations. This significantly enhances on-site clients' confidence in the company's professional capabilities.

3. Sanitisation Station: Contactless Disinfection for Enhanced Safety

Addressing personnel disinfection requirements in production workshops, the unit employs infrared sensing technology to deliver fully contactless disinfection throughout the process, thereby mitigating cross-infection risks. The disinfectant solution is atomised uniformly with extensive coverage, while intelligent adjustment of disinfection duration and concentration accommodates varying hygiene standards across industries.

During the exhibition, the team delivered live equipment demonstrations to vividly showcase the core technological advantages of the machinery, enabling clients to experience its stable performance and user-friendly operation firsthand.

As an innovator in the field of digital printing equipment, the team consistently prioritises technological research and development as its core driving force, dedicated to providing global printing enterprises with more efficient, environmentally friendly, and intelligent solutions. Purification products serve as a ‘differentiating highlight’, filling a gap in industry exhibitions. Through comprehensive matrix displays, they enable customer order requirements to shift from ‘single equipment procurement’ to ‘end-to-end solution procurement’.

Following an in-depth examination of the equipment's performance at the exhibition, numerous international clients expressed strong interest in collaboration, with some even reaching preliminary agreements on the spot. The successful participation in SWOP 2025 not only affirms our existing technological capabilities but also marks a new starting point for future development.

Moving forward, we shall continue to prioritise technological innovation as our core focus, keeping pace with industry trends. Through our comprehensive product portfolio and end-to-end service offerings, we will deliver more efficient, safer and environmentally conscious solutions to global clients, driving the overall transformation and upgrading of both the packaging and printing industry and the purification sector.