- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

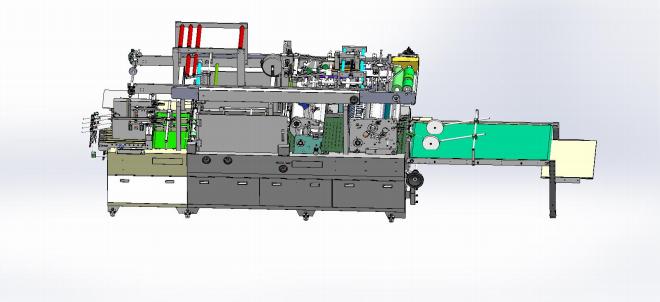

LQ-800H

UPG

STRUCTURE:

This machine is composed of these four units: feeding unit, gluing unit, window patching unit, delivery unit. (The whole machine equipped with safety door device is standard)

1)FEEDING UNIT

Independent servo control motor instead of traditional clutch control system was adopted for intermittent belt conveying. Intermittent delivery distance can be adjusted according to the length of the paper. Paper feeding from the bottom, realized continuous paper feeding without stopping the machine.(Standard single plate type feeder belt with air suction). Compared with traditional machines, the increase of buffer correction mechanism for paper feeding is more stable.(The only one who add the buffer paper feeding mechanism in domestic).

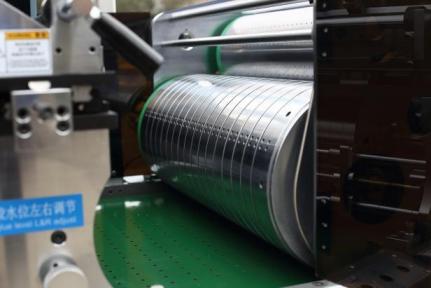

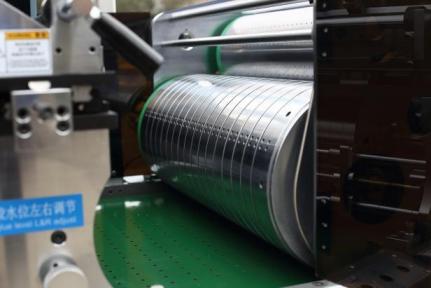

2) GLUING UNIT

Single high-hardness stainless steel tube rollers transmit the glue. The tube rollers are equipped with a sliding block which can quickly regulate glue thickness. Flexible template gluing is adopted, and the template shop can be engraved according to product requirements. The roller for template installation is graved with a base line, and the template installation is accurate, convenient and quick. Left and right position for gluing can be adjusted freely. Front and back position are adjusted with an adjusted which can adjust front, back, left and right position for gluing without shutdown. When being cleaned and maintained, the glue device can be pulled out. It can be cleaned and maintained more conveniently.

3) WINDOW PATCHING UNIT

This part adopts 3 sets of independent servo control system, Users can quickly adjust the length of the film without stopping, or quickly adjust the position of the film according to the size of the product. The upper and lower cutter adopts the original and imported blade from Germany. The belt transmission part can be independently controlled, closing the air hole of the unneeded suction part, making the paper more smoothly.

4)DELIVERY UNIT

Soft conveyor belt can prevent product from crushing. Paper is stacked neatly, which ensures perfect quality.

Technical parameter

Model | LQ-800H |

Blank length(mm) | 100-750mm |

Blank width(mm) | 80-800mm |

Weight of tube material(g/㎡) | 60 g/㎡ min. - 110 g/㎡ max. |

Material outer diameter(mm) | 1000mm |

Tube length(mm) | 80-420mm |

Tube width(mm) | 60-220mm (Other dimensions shall be modified and customized) |

Paper weight | 250-1500 g/㎡≤6mm |

Film Thickness (mm) | 0.03-0.2mm |

Mechanical max. speed | 20000pcs/h |

Positioning accuracy | ± 1mm |

Power voltage | 380v/50Hz |

Machine power (kw) | 12KW |

Machine weight | About 4000KG |

Dimension(L*W*H/mm) | 5980*1470*21600 |

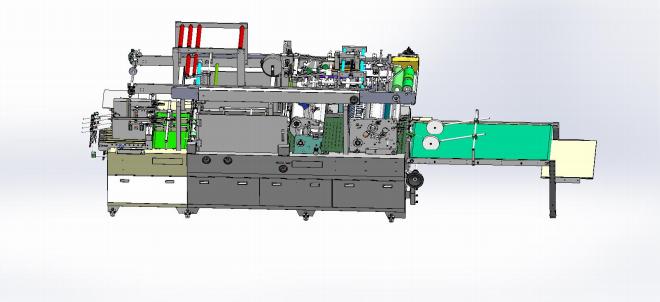

STRUCTURE:

This machine is composed of these four units: feeding unit, gluing unit, window patching unit, delivery unit. (The whole machine equipped with safety door device is standard)

1)FEEDING UNIT

Independent servo control motor instead of traditional clutch control system was adopted for intermittent belt conveying. Intermittent delivery distance can be adjusted according to the length of the paper. Paper feeding from the bottom, realized continuous paper feeding without stopping the machine.(Standard single plate type feeder belt with air suction). Compared with traditional machines, the increase of buffer correction mechanism for paper feeding is more stable.(The only one who add the buffer paper feeding mechanism in domestic).

2) GLUING UNIT

Single high-hardness stainless steel tube rollers transmit the glue. The tube rollers are equipped with a sliding block which can quickly regulate glue thickness. Flexible template gluing is adopted, and the template shop can be engraved according to product requirements. The roller for template installation is graved with a base line, and the template installation is accurate, convenient and quick. Left and right position for gluing can be adjusted freely. Front and back position are adjusted with an adjusted which can adjust front, back, left and right position for gluing without shutdown. When being cleaned and maintained, the glue device can be pulled out. It can be cleaned and maintained more conveniently.

3) WINDOW PATCHING UNIT

This part adopts 3 sets of independent servo control system, Users can quickly adjust the length of the film without stopping, or quickly adjust the position of the film according to the size of the product. The upper and lower cutter adopts the original and imported blade from Germany. The belt transmission part can be independently controlled, closing the air hole of the unneeded suction part, making the paper more smoothly.

4)DELIVERY UNIT

Soft conveyor belt can prevent product from crushing. Paper is stacked neatly, which ensures perfect quality.

Technical parameter

Model | LQ-800H |

Blank length(mm) | 100-750mm |

Blank width(mm) | 80-800mm |

Weight of tube material(g/㎡) | 60 g/㎡ min. - 110 g/㎡ max. |

Material outer diameter(mm) | 1000mm |

Tube length(mm) | 80-420mm |

Tube width(mm) | 60-220mm (Other dimensions shall be modified and customized) |

Paper weight | 250-1500 g/㎡≤6mm |

Film Thickness (mm) | 0.03-0.2mm |

Mechanical max. speed | 20000pcs/h |

Positioning accuracy | ± 1mm |

Power voltage | 380v/50Hz |

Machine power (kw) | 12KW |

Machine weight | About 4000KG |

Dimension(L*W*H/mm) | 5980*1470*21600 |