| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-DA-260

UPG

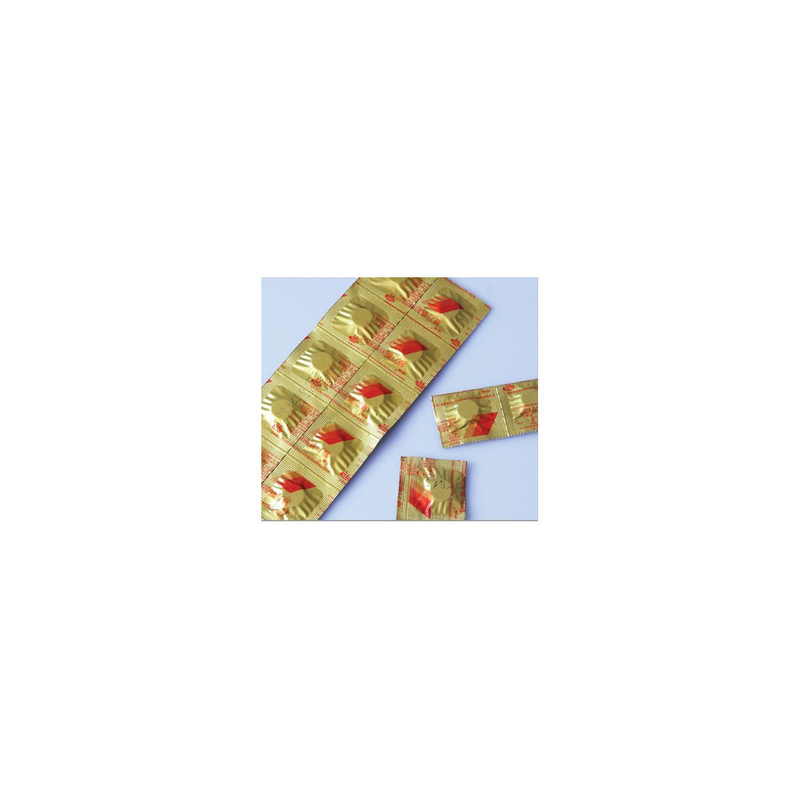

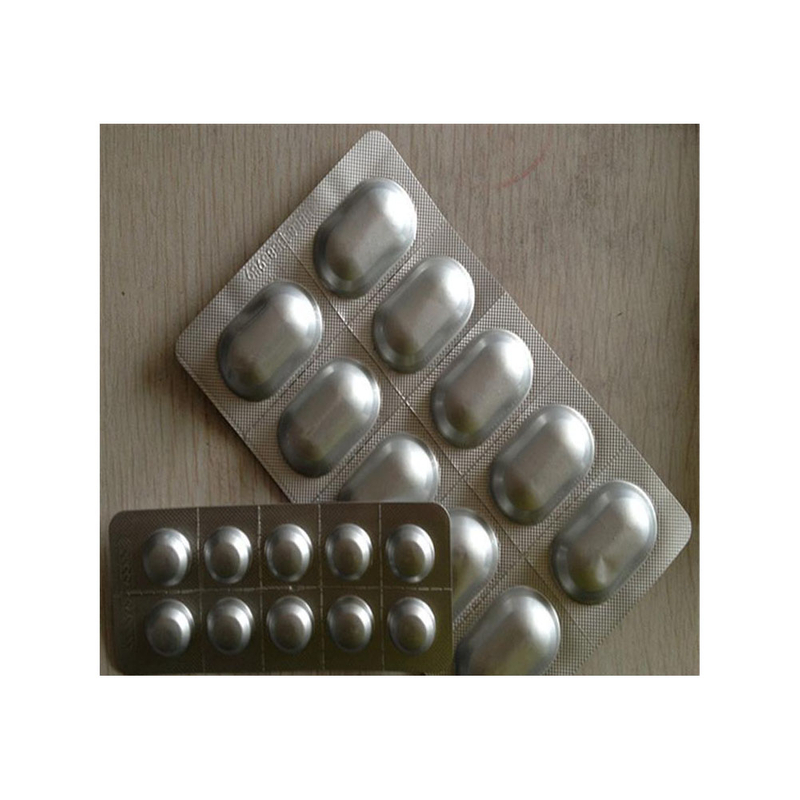

It is suitable for the pharmaceutical industry of packing the tablets, capsules. It plays a good role in sealing and avoiding light.

It is used frequency conversion to adjust speed. After the vibration feeding device of the whole column, photoelectric monitoring device, automatic counting, filling, heat sealing, tangent, batch number printing, cutting and other series of processes, it can be completed automatically and with high-speed operation.

1. The whole machine is installed with programmable controller and touch screen to control each action point. So both sugar-coated or not tablets and capsules can be filled into the two layers of aluminum film and medicine plate is formed. According to the requirement, cutting length can be changed on the touch screen.

2. Imported PID temperature controller and the temperature measurement on the surface of the high PT100 roller are adopted to control the temperature of heat sealing moulding. So the surface temperature of the thermal sealing film is absolutely stable and reliable, and the sealing performance is also improved.

3. This machine is installed imported frequency converter to control speed. And it is also equipped with tear cutting device.

4. We provide two options of printing batch, one is embossing batch using steel figures and the other is solid ink wheel printing in packaging materials.

It is suitable for the pharmaceutical industry of packing the tablets, capsules. It plays a good role in sealing and avoiding light.

It is used frequency conversion to adjust speed. After the vibration feeding device of the whole column, photoelectric monitoring device, automatic counting, filling, heat sealing, tangent, batch number printing, cutting and other series of processes, it can be completed automatically and with high-speed operation.

1. The whole machine is installed with programmable controller and touch screen to control each action point. So both sugar-coated or not tablets and capsules can be filled into the two layers of aluminum film and medicine plate is formed. According to the requirement, cutting length can be changed on the touch screen.

2. Imported PID temperature controller and the temperature measurement on the surface of the high PT100 roller are adopted to control the temperature of heat sealing moulding. So the surface temperature of the thermal sealing film is absolutely stable and reliable, and the sealing performance is also improved.

3. This machine is installed imported frequency converter to control speed. And it is also equipped with tear cutting device.

4. We provide two options of printing batch, one is embossing batch using steel figures and the other is solid ink wheel printing in packaging materials.

| Model | LQ-DA-260 |

| Production Capacity | 1400pcs/min According to packing size |

| Blanking Frequency | 20-50times/min |

| Max.Packaging Width | 260mm |

| Polythene Film Size | (0.05mm-0.1mm)*260mm |

| Dia. Of Polythene Film | 300mm |

| Al. Compound Packing Film Size | 0.08mm*260mm |

| Dia. Of Al. Compound Packing Film | 300mm |

| Air Supply | 0.45 Mpa |

| Air Flow | 0.2m3/min |

| Power | 3.75 kw |

| Overall Dimension (L*W*H) | 1600mm*850mm*1900mm |

| Weight | 1000 kg |

| Model | LQ-DA-260 |

| Production Capacity | 1400pcs/min According to packing size |

| Blanking Frequency | 20-50times/min |

| Max.Packaging Width | 260mm |

| Polythene Film Size | (0.05mm-0.1mm)*260mm |

| Dia. Of Polythene Film | 300mm |

| Al. Compound Packing Film Size | 0.08mm*260mm |

| Dia. Of Al. Compound Packing Film | 300mm |

| Air Supply | 0.45 Mpa |

| Air Flow | 0.2m3/min |

| Power | 3.75 kw |

| Overall Dimension (L*W*H) | 1600mm*850mm*1900mm |

| Weight | 1000 kg |