| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

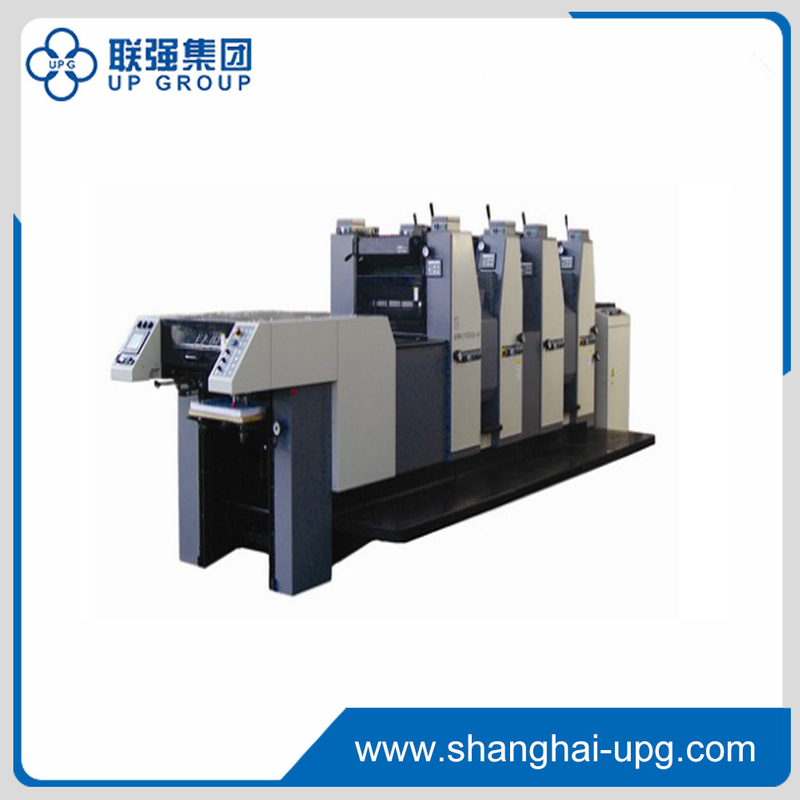

LQIN-524

UPG

Max. Paper Size | 520mmx375mm |

Min. Paper Size | 200mmx155mm |

Paper Thickness | 0.04mm-0.4mm |

Max. Printing Area | 505mmx350mm |

Printing Speed | 3000-12000 sheets/hour |

Plate Size | 510mmx400mm |

Blanket Size | 528mmx437mmx1.9mm |

Under Blanket Size | 505mm x389mmx0.6mm |

Number of Rollers | 17 Ink rollers; 4 Water rollers |

Gripper Margin | 9mm±1mm |

Vertical Image Adjustment Range | ±20mm |

Lateral Image Micro Adjustment Range | ±1mm |

Inclined Image Micro Adjustment Range | ±0.15mm |

Oiling System | Centralized Oiling System |

Power Source | 3 Phase 380V/50Hz |

Overall Dimensions | 5860mmx2300mmx1710mm |

Net Weight | 9000Kg |

1. Heavy duty mechanism structure. Cast iron pedestal, frame, cylinders etc. have the good intension and tenacity, ensuring high stability and good printing impression.

2. Underswing feeder, paper transferring structure is used, high point gripper closed structure, insuring paper transferring system more stably.

3. Double diameter impression cylinder and triple diameter transferring cylinder are available, reducing the times of paper connection, improving register precision.

4. Plate cylinder and blanket cylinder go through with bearer, running stably, ensuring qualified printing image.

5. Pneumatic control system, ensuring the press more stably.

6. High precision imported bearing, ensuring cylinder impression even in the high speed rotation.

7. Chromed cylinder, prolongs the operation life.

8. Automatic centralized oiling system, prolongs the working life.

9. Operators are under protection because of the installation of safety guard, adjustment door and protecting shield.

10. Plate adjustment function in vertical lateral and cocking position. The minimum adjustment is based on 0.01mm, saving auxiliary adjustment time.

11. Semi-automatic plate loader and tightening equipment, make the plate loading more easy and convenient, shorten plate changing time, improving working efficiency.

12. Paper fed continuously and stably, more suitable for thick and thin paper printing.

13. Vacuum sucker table, 3 sucker type paper feed tape insures all kinds of paper conveying.

14. Special design in paper feed head, paper board, paper board, front

Max. Paper Size | 520mmx375mm |

Min. Paper Size | 200mmx155mm |

Paper Thickness | 0.04mm-0.4mm |

Max. Printing Area | 505mmx350mm |

Printing Speed | 3000-12000 sheets/hour |

Plate Size | 510mmx400mm |

Blanket Size | 528mmx437mmx1.9mm |

Under Blanket Size | 505mm x389mmx0.6mm |

Number of Rollers | 17 Ink rollers; 4 Water rollers |

Gripper Margin | 9mm±1mm |

Vertical Image Adjustment Range | ±20mm |

Lateral Image Micro Adjustment Range | ±1mm |

Inclined Image Micro Adjustment Range | ±0.15mm |

Oiling System | Centralized Oiling System |

Power Source | 3 Phase 380V/50Hz |

Overall Dimensions | 5860mmx2300mmx1710mm |

Net Weight | 9000Kg |

1. Heavy duty mechanism structure. Cast iron pedestal, frame, cylinders etc. have the good intension and tenacity, ensuring high stability and good printing impression.

2. Underswing feeder, paper transferring structure is used, high point gripper closed structure, insuring paper transferring system more stably.

3. Double diameter impression cylinder and triple diameter transferring cylinder are available, reducing the times of paper connection, improving register precision.

4. Plate cylinder and blanket cylinder go through with bearer, running stably, ensuring qualified printing image.

5. Pneumatic control system, ensuring the press more stably.

6. High precision imported bearing, ensuring cylinder impression even in the high speed rotation.

7. Chromed cylinder, prolongs the operation life.

8. Automatic centralized oiling system, prolongs the working life.

9. Operators are under protection because of the installation of safety guard, adjustment door and protecting shield.

10. Plate adjustment function in vertical lateral and cocking position. The minimum adjustment is based on 0.01mm, saving auxiliary adjustment time.

11. Semi-automatic plate loader and tightening equipment, make the plate loading more easy and convenient, shorten plate changing time, improving working efficiency.

12. Paper fed continuously and stably, more suitable for thick and thin paper printing.

13. Vacuum sucker table, 3 sucker type paper feed tape insures all kinds of paper conveying.

14. Special design in paper feed head, paper board, paper board, front

Max. Paper Size | 520mmx375mm |

Min. Paper Size | 200mmx155mm |

Paper Thickness | 0.04mm-0.4mm |

Max. Printing Area | 505mmx350mm |

Printing Speed | 3000-12000 sheets/hour |

Plate Size | 510mmx400mm |

Blanket Size | 528mmx437mmx1.9mm |

Under Blanket Size | 505mm x389mmx0.6mm |

Number of Rollers | 17 Ink rollers; 4 Water rollers |

Gripper Margin | 9mm±1mm |

Vertical Image Adjustment Range | ±20mm |

Lateral Image Micro Adjustment Range | ±1mm |

Inclined Image Micro Adjustment Range | ±0.15mm |

Oiling System | Centralized Oiling System |

Power Source | 3 Phase 380V/50Hz |

Overall Dimensions | 5860mmx2300mmx1710mm |

Net Weight | 9000Kg |

Max. Paper Size | 520mmx375mm |

Min. Paper Size | 200mmx155mm |

Paper Thickness | 0.04mm-0.4mm |

Max. Printing Area | 505mmx350mm |

Printing Speed | 3000-12000 sheets/hour |

Plate Size | 510mmx400mm |

Blanket Size | 528mmx437mmx1.9mm |

Under Blanket Size | 505mm x389mmx0.6mm |

Number of Rollers | 17 Ink rollers; 4 Water rollers |

Gripper Margin | 9mm±1mm |

Vertical Image Adjustment Range | ±20mm |

Lateral Image Micro Adjustment Range | ±1mm |

Inclined Image Micro Adjustment Range | ±0.15mm |

Oiling System | Centralized Oiling System |

Power Source | 3 Phase 380V/50Hz |

Overall Dimensions | 5860mmx2300mmx1710mm |

Net Weight | 9000Kg |