| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

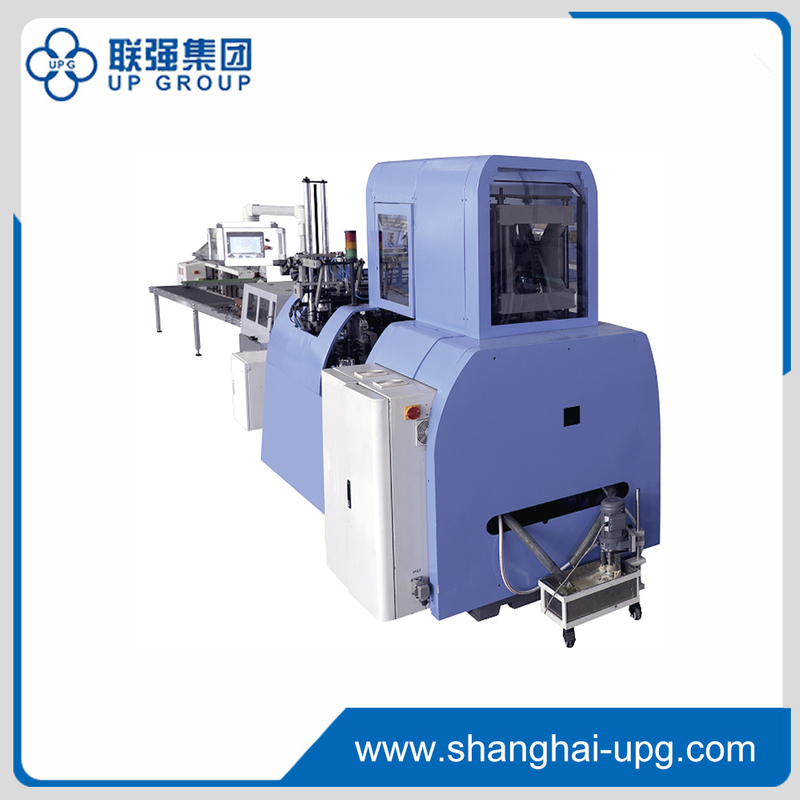

LQ-AUSCP-RK50

UPG

Product application:

This machine is designed for casing-in hardcover books or notebooks, lt is suitable for both rigid and flexible covers

Product composition:

The machine consists of a control system, pre-positioning mechanism, book block feeding mechanism, book block conveyor, book block positioning unit, cover separation mechanism, cover shaping unit, cover conveyor, book block gluing mechanism, casing-in unit, transmission system, and a book collection unit. This machine is designed for hardcover book processing, it uses photoelectric monitoring to provide real-time control and ensure precise operations during production.

Functions & features:

· Storage and Memory: The machine can store historical data for easy recall and allows for presetting and saving of new data.

· Automatic Adjustments: Users input the dimensions of the book block and cover length, width, thickness) via a touchscreen. A servo drive system automatically adjusts nine parameters including the cover conveyor length and width, cover rounding, cover positioning, book block transport height, chain grip, and book block positioning in both width and length, ensuring convenience, precision, and high efficiency when changing specifications.

· Fault Detection: Alerts are issued, and the machine stops automatically upon any malfunction, with the fault displayed onscreen.

· Book block Positioning: individual book block are fed into the conveyor chain, pre-positioned, and delivered to the positioning unit by a chain equipped with a delivery rod, which separates and accurately positions the book block.

· Gluing: After positioning, the book block is moved upwards by a lifting knife and passes through a rotating gluing roller. The textured rollers cater specifically to rounded spine gluing requirements.

· Cover Shaping: individual covers are fed through the separation unit into the cover shaping area where they are fattened and rounded by heated rollers to achieve the required curvature.

· Cover Positioning: Shaped covers are pushed forward for precise positioning by the conveyor system.

· Casing-In: The glued book block and positioned cover are lifted to the casing-in unit, where the combination is completed.

· Book Collection: Completed books (notebooks) are released from the lifting knife and gently guided onto a conveyor belt for output.

· Automatic Lubrication: The machine features a timed and quantified lubrication system that ensures all major lubrication points receive oil during operation.

Technical Data:

Open Cover Size | Max: 620×360 mm Min: 210×135 mm |

Cover Thickness Range | 1-5 mm |

Book Block Size | Max: 270×360 mm Min: 100×125 mm |

Book Block Thickness Range | 4-60 mm |

Max. Speed | 50 books/min |

Main Motor Power | 3.5 kw |

Total Power | 9.34 kw |

Voltage Requirement | 380 V |

Frequency | 380 V, 50 Hz |

Machine Weight | 5500 kg |

Dimensions | 4805×2115×2500mm |

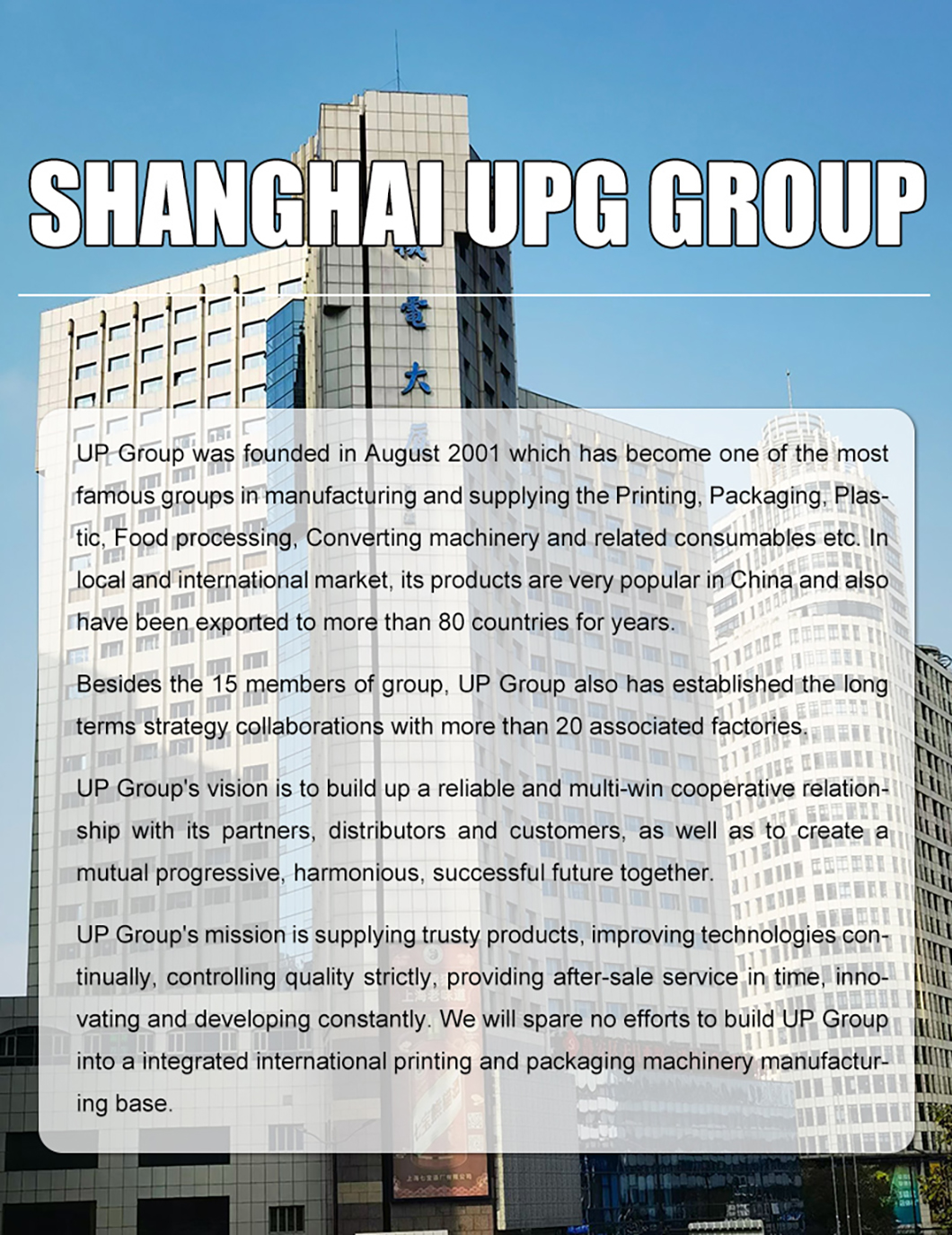

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

Product application:

This machine is designed for casing-in hardcover books or notebooks, lt is suitable for both rigid and flexible covers

Product composition:

The machine consists of a control system, pre-positioning mechanism, book block feeding mechanism, book block conveyor, book block positioning unit, cover separation mechanism, cover shaping unit, cover conveyor, book block gluing mechanism, casing-in unit, transmission system, and a book collection unit. This machine is designed for hardcover book processing, it uses photoelectric monitoring to provide real-time control and ensure precise operations during production.

Functions & features:

· Storage and Memory: The machine can store historical data for easy recall and allows for presetting and saving of new data.

· Automatic Adjustments: Users input the dimensions of the book block and cover length, width, thickness) via a touchscreen. A servo drive system automatically adjusts nine parameters including the cover conveyor length and width, cover rounding, cover positioning, book block transport height, chain grip, and book block positioning in both width and length, ensuring convenience, precision, and high efficiency when changing specifications.

· Fault Detection: Alerts are issued, and the machine stops automatically upon any malfunction, with the fault displayed onscreen.

· Book block Positioning: individual book block are fed into the conveyor chain, pre-positioned, and delivered to the positioning unit by a chain equipped with a delivery rod, which separates and accurately positions the book block.

· Gluing: After positioning, the book block is moved upwards by a lifting knife and passes through a rotating gluing roller. The textured rollers cater specifically to rounded spine gluing requirements.

· Cover Shaping: individual covers are fed through the separation unit into the cover shaping area where they are fattened and rounded by heated rollers to achieve the required curvature.

· Cover Positioning: Shaped covers are pushed forward for precise positioning by the conveyor system.

· Casing-In: The glued book block and positioned cover are lifted to the casing-in unit, where the combination is completed.

· Book Collection: Completed books (notebooks) are released from the lifting knife and gently guided onto a conveyor belt for output.

· Automatic Lubrication: The machine features a timed and quantified lubrication system that ensures all major lubrication points receive oil during operation.

Technical Data:

Open Cover Size | Max: 620×360 mm Min: 210×135 mm |

Cover Thickness Range | 1-5 mm |

Book Block Size | Max: 270×360 mm Min: 100×125 mm |

Book Block Thickness Range | 4-60 mm |

Max. Speed | 50 books/min |

Main Motor Power | 3.5 kw |

Total Power | 9.34 kw |

Voltage Requirement | 380 V |

Frequency | 380 V, 50 Hz |

Machine Weight | 5500 kg |

Dimensions | 4805×2115×2500mm |

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.