LQ-HL

UPG

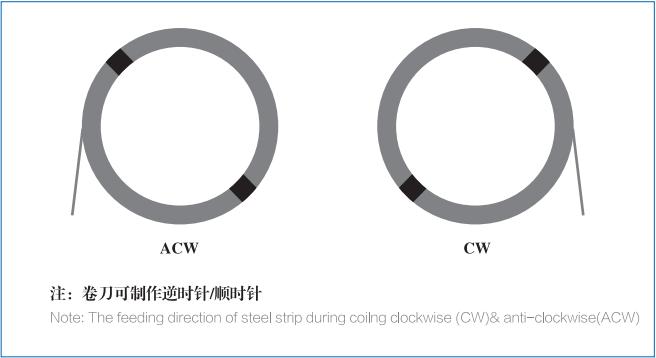

1. Used for forming of all kinds adhesive labels

2. Can be bend to any geometrical shape

Material:□CN □JP □GM

Edge:A:单锋刀CB B双锋刀LCB

Summary of constituent elements of die cutting knife

Knife Type | Low-bladed Knife/High-bladed Knife with two-stage/Single-Sided Knife/Wave Knife/Tooth Knife/Combination knife |

Steel Type | /S50C/C55 |

Thickness(mm) | 0.45/0.53/2pt/3pt/4pt/6pt |

Height(mm) | 7.0/8.0/9.5/12/23.5/23.6/23.7/23.8/30~100mm |

Body hardness (Hrc) | 33/37/41/45/48/ |

Blade hardnes(Hrc) | 54/56/58/60/ |

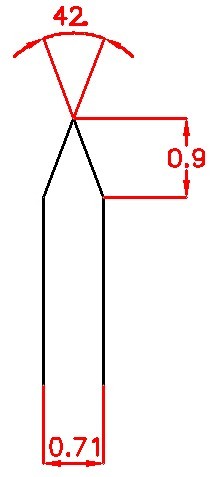

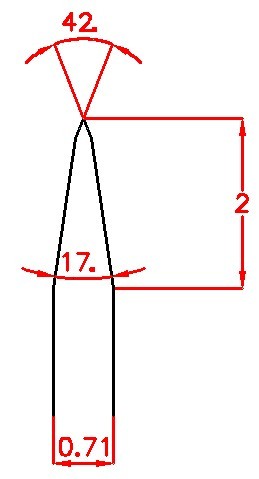

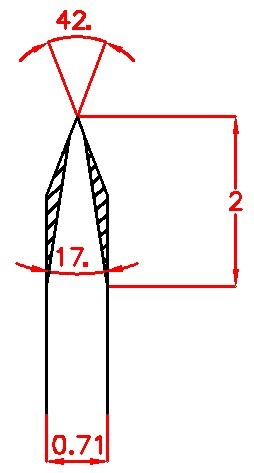

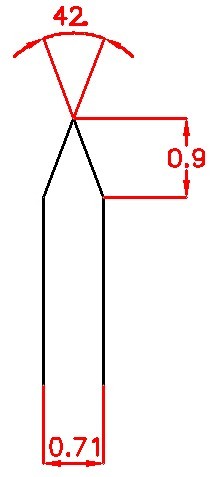

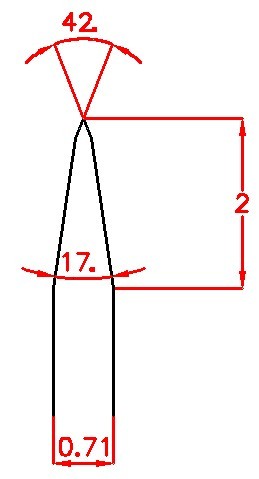

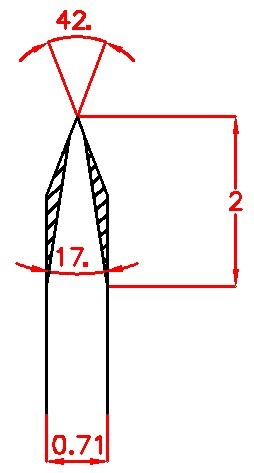

Blade Angle | ∠30° ∠42° ∠52° |

Others | High frequency heat treatment hardening, knife edge grinding, knife edge mirror processing. |

Thickness tolerance range of CUTTING rules

Thickness Expression | Reference | International Standard | Corporate Standards | |

Tolerance | Min~Max | |||

0.45 | 0.44 | ±0.025 | ± 0.010 | 0.430~0.450 |

2PT | 0.71 | ±0.030 | ± 0.010 | 0.700~0.720 |

3PT | 1.05 | ±0.040 | ± 0.010 | 1.050~1.070 |

4PT | 1.42 | ±0.050 | ± 0.015 | 1.395~1.425 |

Impact of Blade Angle on Product

Blade Selection

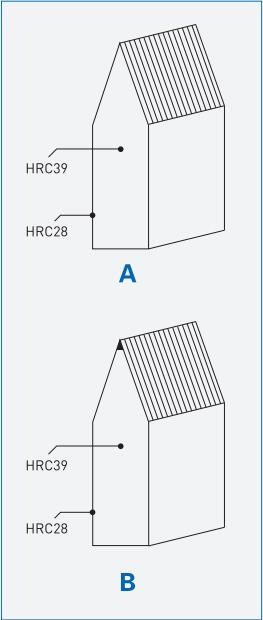

1、Difference of High-edged and Low-edged Knives

Low-Edged Knife High-Edged Knife Difference

The difference between high-edged and low-edged knives is that the high-edged knife is based on the low-edged knife and then grinds off the corners on both sides to make its blade narrower, generally about 2mm

Package

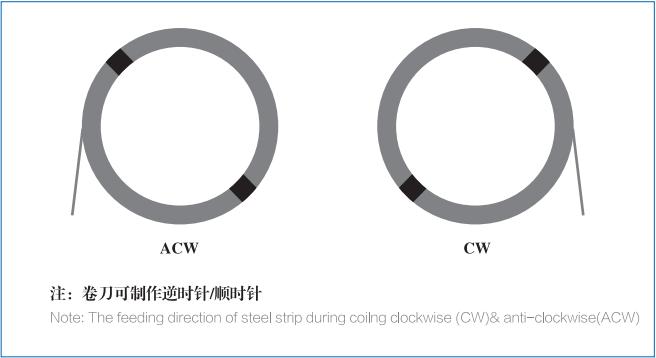

Thickness | Carton Box quantity | Coil |

0.45mm(1.27PT) | 100Pcs/Box | 100M/Coil |

0.53mm(1.5PT) | 100Pcs/Box | 100M/Coil |

0.71mm(2PT) | 100Pcs/Box | 100M/Coil |

1.07mm(3PT) | 70Pcs/Box | 70M/Coil |

1.42mm(4PT) | 50Pcs/Box | 50M/Coil |

2.10mm(6PT) | 35Pcs/Box | 35M/Coil |

Application area

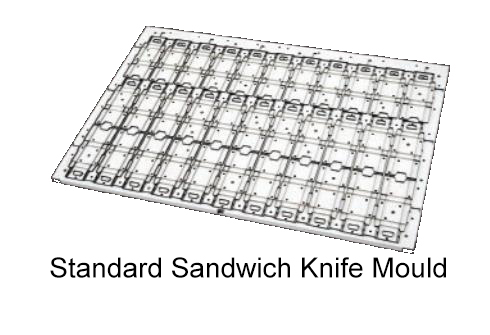

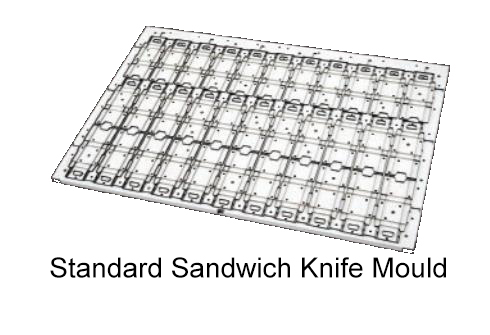

Die-Cutting for packaging box

1. Used for forming of all kinds adhesive labels

2. Can be bend to any geometrical shape

Material:□CN □JP □GM

Edge:A:单锋刀CB B双锋刀LCB

Summary of constituent elements of die cutting knife

Knife Type | Low-bladed Knife/High-bladed Knife with two-stage/Single-Sided Knife/Wave Knife/Tooth Knife/Combination knife |

Steel Type | /S50C/C55 |

Thickness(mm) | 0.45/0.53/2pt/3pt/4pt/6pt |

Height(mm) | 7.0/8.0/9.5/12/23.5/23.6/23.7/23.8/30~100mm |

Body hardness (Hrc) | 33/37/41/45/48/ |

Blade hardnes(Hrc) | 54/56/58/60/ |

Blade Angle | ∠30° ∠42° ∠52° |

Others | High frequency heat treatment hardening, knife edge grinding, knife edge mirror processing. |

Thickness tolerance range of CUTTING rules

Thickness Expression | Reference | International Standard | Corporate Standards | |

Tolerance | Min~Max | |||

0.45 | 0.44 | ±0.025 | ± 0.010 | 0.430~0.450 |

2PT | 0.71 | ±0.030 | ± 0.010 | 0.700~0.720 |

3PT | 1.05 | ±0.040 | ± 0.010 | 1.050~1.070 |

4PT | 1.42 | ±0.050 | ± 0.015 | 1.395~1.425 |

Impact of Blade Angle on Product

Blade Selection

1、Difference of High-edged and Low-edged Knives

Low-Edged Knife High-Edged Knife Difference

The difference between high-edged and low-edged knives is that the high-edged knife is based on the low-edged knife and then grinds off the corners on both sides to make its blade narrower, generally about 2mm

Package

Thickness | Carton Box quantity | Coil |

0.45mm(1.27PT) | 100Pcs/Box | 100M/Coil |

0.53mm(1.5PT) | 100Pcs/Box | 100M/Coil |

0.71mm(2PT) | 100Pcs/Box | 100M/Coil |

1.07mm(3PT) | 70Pcs/Box | 70M/Coil |

1.42mm(4PT) | 50Pcs/Box | 50M/Coil |

2.10mm(6PT) | 35Pcs/Box | 35M/Coil |

Application area

Die-Cutting for packaging box

Thickness | 0.45mm(1.27PT) | 0.53mm(1.5PT) |

Height | 7.0-12.0mm |

Specification Thickness | Number | Color of body | Remark |

0.45mm | LQHL-50 | White Edge | Core Hardness HRC41-43 |

LQHL-60 | Black Edge | Core Hardness HRC39-40 | |

LQHL-70 | White Body | Core Hardness HRC39-40 | |

LQHL-80 | Gold Body | Core Hardness HRC39-40 |

Thickness | 0.45mm(1.27PT) | 0.53mm(1.5PT) |

Height | 7.0-12.0mm |

Specification Thickness | Number | Color of body | Remark |

0.45mm | LQHL-50 | White Edge | Core Hardness HRC41-43 |

LQHL-60 | Black Edge | Core Hardness HRC39-40 | |

LQHL-70 | White Body | Core Hardness HRC39-40 | |

LQHL-80 | Gold Body | Core Hardness HRC39-40 |