| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD 4400HD/5600HD

UPG

Product Parameters:

1200DPl Mono-Color Inkjet Press Technical Specifications

| Printing mode | LQ-MD 4400HD | LQ-MD 5600HD |

| Technical Specifications | ||

| Printing type | Monochrome duplex | |

| Resolution | 1200x1200dpi、1200x960dpi、1200x840dpi、1200x600dpi | |

| Print speed | 150mmin Max* | |

| Connect Cutter speed | 100m/min Max* | |

| Registration accuracy | ±0.5mm(Front and back) | |

| Printhead | Industrial Drop-on-demand Piezoelectric | |

| Ink droplet size | 1.5pl、3pl、5pl | |

| Ink | Water-based pigment ink | |

| Dry method | Infrared dryer (automatic adjustment on printing speed) | |

| Digital front-end | Eagle Jetinkjet™ imaging system (Windows Server based) | |

| Paper | ||

| Max. media width | 560mm | 560mm |

| Max. printing width | 440mm | 540mm |

| Paper type | Uncoated paper, inkjet coated paper, newspaper# | |

| Media thickness | 45 gsm -165 gsm | |

| Max.roll diameter | 1270mm | |

| AC power | ||

| Mechanical platform | 380Vac115KW | |

| Dryer system | 380Vac135KW Max | |

| Digital controller system | 220Vac13KW | |

| Operating Environment | ||

| Temperature | 22 5-27 5℃℃,the best working temperature is 25℃ | |

| Humidity | 40-70RH, no condensation, the best working humidity is 50-60%RH | |

*The actual speed is influenced by different papers and files.

#The brand and specifications recommended by Party B.

Digital Printing Cutting System Technical Specifications

| Items | Parameters |

| Cutting speed | 137m/min,connect inkjet press 100m/min(max.speed)* |

| Paper Weight | 40g-200g(Some papers need to be texted.) |

| Web width | 140-560mm |

| Stack length | 90mm-710mm |

| Stack height | 250mm |

| Max.stagger distance | 15mm |

| Power | 220V,50HZ,10A |

*The actual speed is influenced by different papers and files

Product Description:

Ultra-Low Ink Cost

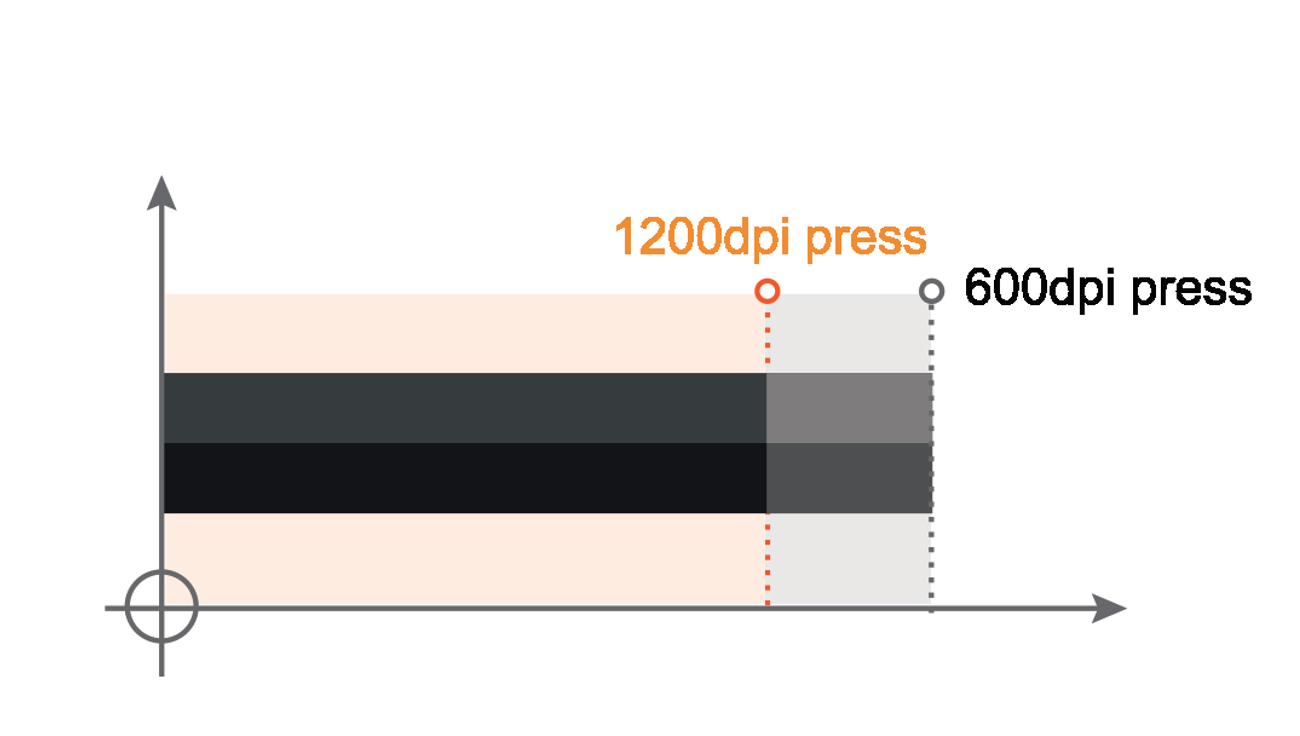

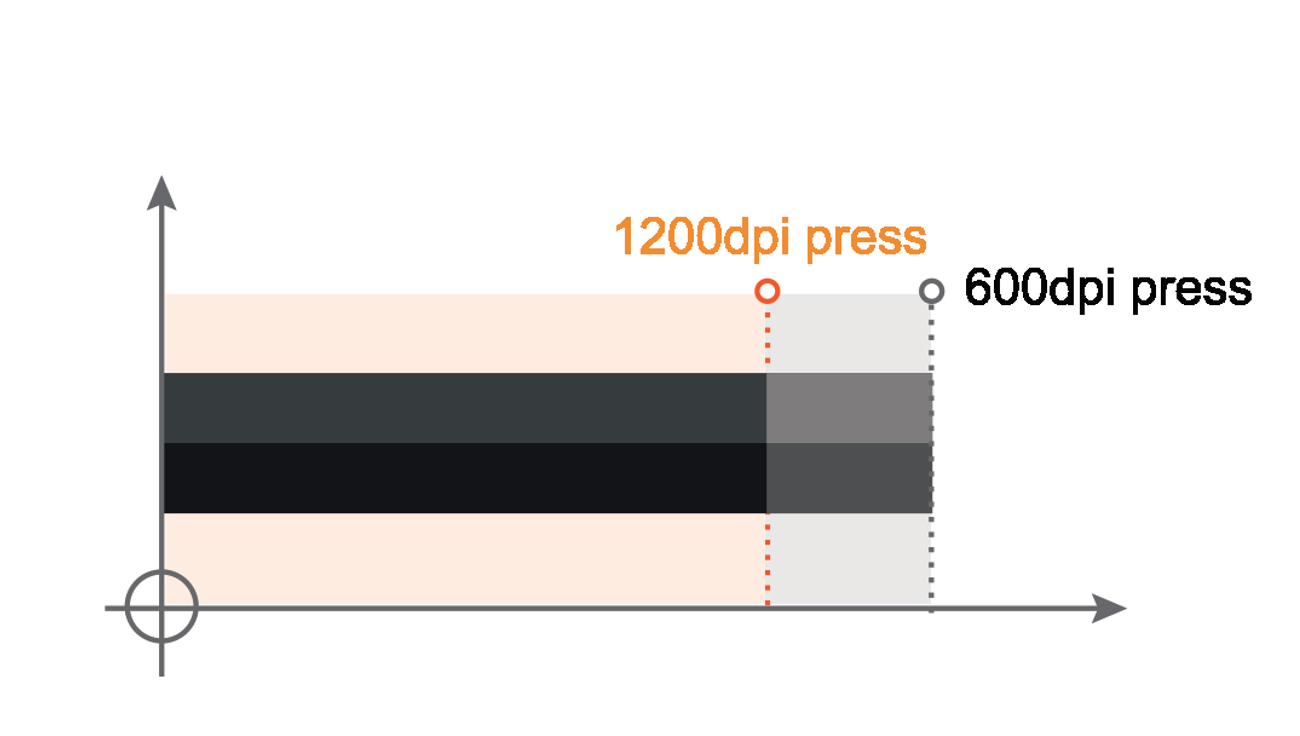

Improved Screening Technology

Better Printing Quality with Less ink Amount. Compared with 600dpi color presses, the ink amount in HD presses can be saved by 30%-40% under the same printing conditions.

UPGJET also developed an ink calculator, which helps to estimate the ink consumption before printing.

Upgraded Ink Supply Technology

The latest sixth-generation circulating ink supply system greatly reduces nozzle clogging, which decreases ink wasted in cleaning maintenance by 50%.

Super Long Service Life

Casting Frame

Casting structure and advanced assembly technology applied on the base and wallboard of the mechanical platform ensure the structural stability and shock resistance of the whole machine in long-term operation, which helps to match the service life of offset presses.

The servo control system from well-known brands is accurate, stable, and durable, which is reliable to ensure safe and stable paper transmission, matched with paper breakage, double sheet and tail detection, etc.

Digital Printing Cutting System

Minimize the Downtime Caused By Nozzle Clogging

Circulating ink supply technology with online detection (optional) greatly reduces the probability of nozzle clogging, and at the same time realizes the function of automatic white-ine compensation, which protects the whole printing of one or more jobs, without stopping to maintain nozzles.

Efficient Paper Roll Replacement

The new-generation presses continue the UPGJET's convenient operation design of uncoling system for paper rolloading and unloading, which ensures efficient paper roll replacement.

Multi-technology avoids wrinkles and dirt of large-ink jobs in high-speed production.

The upgraded drying system highly improved the drying capacity of large-ink-amount jobs.

The page ink drop processing technology can reduce separately target ink for pages with super-large ink amounts, which realizes the high-quality printing of the whole job.

Digital Printing Cutting System

Introduce the post-press technology of internationally famous manufacturers.

With international quality standards, UPGJET greatly reduces the equipment investment, and at the same time guarantees the production stability of UPGJET inkjet presses to the greatest extent.

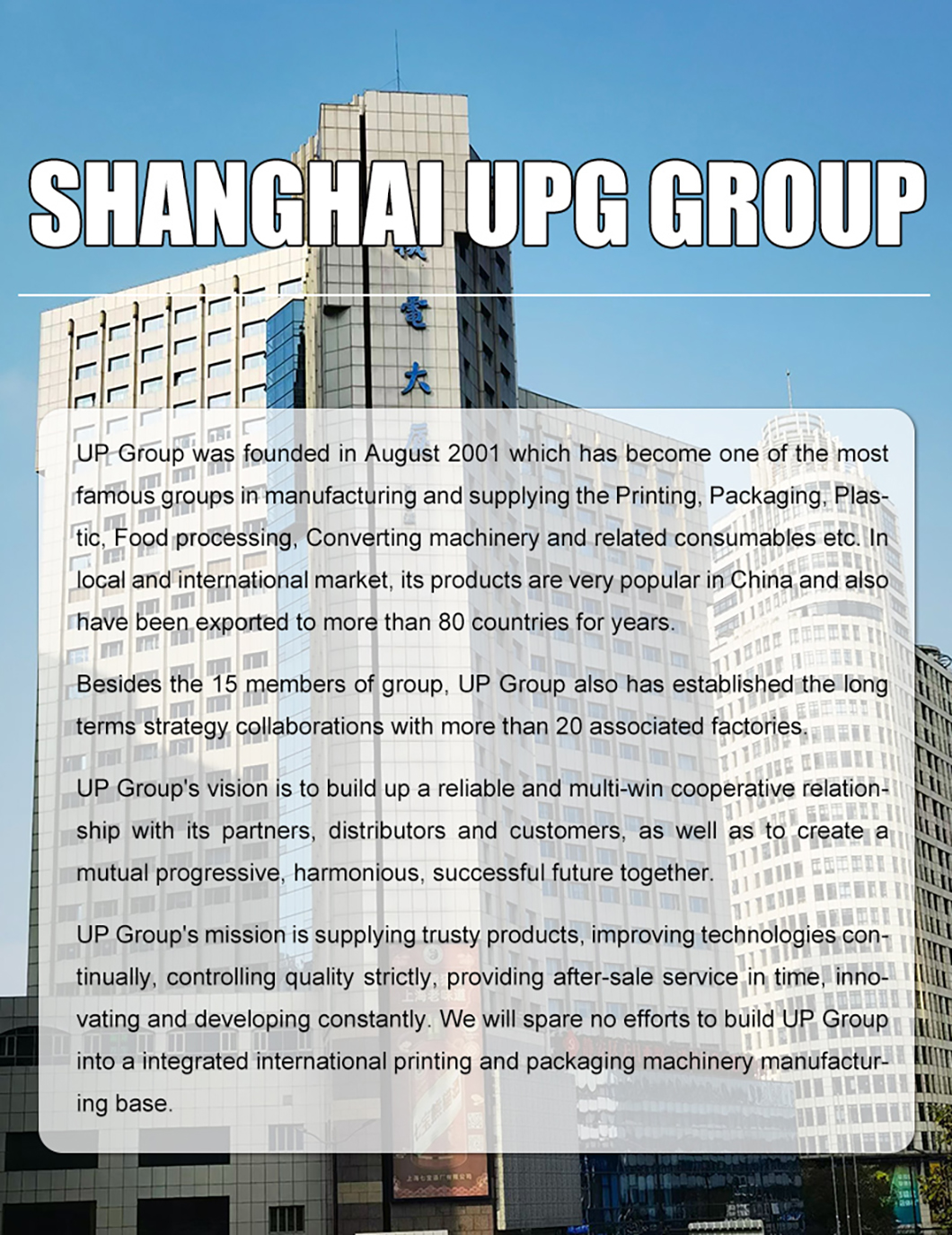

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

Product Parameters:

1200DPl Mono-Color Inkjet Press Technical Specifications

| Printing mode | LQ-MD 4400HD | LQ-MD 5600HD |

| Technical Specifications | ||

| Printing type | Monochrome duplex | |

| Resolution | 1200x1200dpi、1200x960dpi、1200x840dpi、1200x600dpi | |

| Print speed | 150mmin Max* | |

| Connect Cutter speed | 100m/min Max* | |

| Registration accuracy | ±0.5mm(Front and back) | |

| Printhead | Industrial Drop-on-demand Piezoelectric | |

| Ink droplet size | 1.5pl、3pl、5pl | |

| Ink | Water-based pigment ink | |

| Dry method | Infrared dryer (automatic adjustment on printing speed) | |

| Digital front-end | Eagle Jetinkjet™ imaging system (Windows Server based) | |

| Paper | ||

| Max. media width | 560mm | 560mm |

| Max. printing width | 440mm | 540mm |

| Paper type | Uncoated paper, inkjet coated paper, newspaper# | |

| Media thickness | 45 gsm -165 gsm | |

| Max.roll diameter | 1270mm | |

| AC power | ||

| Mechanical platform | 380Vac115KW | |

| Dryer system | 380Vac135KW Max | |

| Digital controller system | 220Vac13KW | |

| Operating Environment | ||

| Temperature | 22 5-27 5℃℃,the best working temperature is 25℃ | |

| Humidity | 40-70RH, no condensation, the best working humidity is 50-60%RH | |

*The actual speed is influenced by different papers and files.

#The brand and specifications recommended by Party B.

Digital Printing Cutting System Technical Specifications

| Items | Parameters |

| Cutting speed | 137m/min,connect inkjet press 100m/min(max.speed)* |

| Paper Weight | 40g-200g(Some papers need to be texted.) |

| Web width | 140-560mm |

| Stack length | 90mm-710mm |

| Stack height | 250mm |

| Max.stagger distance | 15mm |

| Power | 220V,50HZ,10A |

*The actual speed is influenced by different papers and files

Product Description:

Ultra-Low Ink Cost

Improved Screening Technology

Better Printing Quality with Less ink Amount. Compared with 600dpi color presses, the ink amount in HD presses can be saved by 30%-40% under the same printing conditions.

UPGJET also developed an ink calculator, which helps to estimate the ink consumption before printing.

Upgraded Ink Supply Technology

The latest sixth-generation circulating ink supply system greatly reduces nozzle clogging, which decreases ink wasted in cleaning maintenance by 50%.

Super Long Service Life

Casting Frame

Casting structure and advanced assembly technology applied on the base and wallboard of the mechanical platform ensure the structural stability and shock resistance of the whole machine in long-term operation, which helps to match the service life of offset presses.

The servo control system from well-known brands is accurate, stable, and durable, which is reliable to ensure safe and stable paper transmission, matched with paper breakage, double sheet and tail detection, etc.

Digital Printing Cutting System

Minimize the Downtime Caused By Nozzle Clogging

Circulating ink supply technology with online detection (optional) greatly reduces the probability of nozzle clogging, and at the same time realizes the function of automatic white-ine compensation, which protects the whole printing of one or more jobs, without stopping to maintain nozzles.

Efficient Paper Roll Replacement

The new-generation presses continue the UPGJET's convenient operation design of uncoling system for paper rolloading and unloading, which ensures efficient paper roll replacement.

Multi-technology avoids wrinkles and dirt of large-ink jobs in high-speed production.

The upgraded drying system highly improved the drying capacity of large-ink-amount jobs.

The page ink drop processing technology can reduce separately target ink for pages with super-large ink amounts, which realizes the high-quality printing of the whole job.

Digital Printing Cutting System

Introduce the post-press technology of internationally famous manufacturers.

With international quality standards, UPGJET greatly reduces the equipment investment, and at the same time guarantees the production stability of UPGJET inkjet presses to the greatest extent.

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

High Quality Completely Comparable to Offset Printing

1.High-Precision Printhead

With the help of industrial piezoelectricity of 1200DP and more sophisticated technology for controlling the combination of multi-level ink droplets, the printed image is presented perfectly with minimal graininess, smoother color tones and richer gradations.

2.High-precision Printhead Assembly

High-precision alloy materials as well as advanced processing and assembling technologies are adopted to ensure precisely utilizing of the printhead.

3.Specific High-Performance Ink

The specific aqueous pigment ink made by top ink manufacturers could be applied to a wider range of paper, with is excellent permeability and adhesion characteristics, color saturation, and drying performance.

4.New Mechanical Platform

Perfect spray shape and precision of ink droplets are realized by controlling printhead height accurately.

The structure of the roll group and assembly process have been optimized precisely, which ensures the roll-to-roll stability of paper running in the state of high speed up to 150m/min.

Unique And Reliable Synchronous control technology at High Speed.

The encoder combined with blue-ray technology supports The encoder combined with blue-ray technology supports the paper moving, which improves effectively to ensure registration accuracy and uniformity of color tones.

Brand-New Closed-Loop Tension Control System

Real-time tension compensation and digital control are realized during running, which fully guarantees the stability of moving paper and thus greatly enhances the stability of high-speed printing.

5.New Inkjet Screening Technology

Based on the "Founder inkjet halftone screening technology" dedicated to Founder inkjet equipment, combined with the characteristics of 1200dpi printhead and permeability and adhesion of ink on paper, the multi-bit depth variable ink-droplet screening technology was specifically designed to intelligently distribute the ink-droplet size and configure automatically best screening mode.

This screening technology has presented better printing quality with less ink amount, which reduces the drying requirements of pages with large ink amounts and thus effectively improves the printing stability of large-ink pages at high speed.

6.Founder Color Tools Color Management Technology (Inkjet Version)

Combined with the characteristics of inkjet technology a number of technological innovations have been broken through, such as workflow color management technology, Al color separation control technology, etc. These technologies not only realize the one-key operation of linear calibration of industrial inkjet printing but also significantly improve the brightness and smoothness of the output image.

By improving the algorithm of color and screening, extremely high light dots can be shown on the paper, so that the gradient level can be optimized.

High Quality Completely Comparable to Offset Printing

1.High-Precision Printhead

With the help of industrial piezoelectricity of 1200DP and more sophisticated technology for controlling the combination of multi-level ink droplets, the printed image is presented perfectly with minimal graininess, smoother color tones and richer gradations.

2.High-precision Printhead Assembly

High-precision alloy materials as well as advanced processing and assembling technologies are adopted to ensure precisely utilizing of the printhead.

3.Specific High-Performance Ink

The specific aqueous pigment ink made by top ink manufacturers could be applied to a wider range of paper, with is excellent permeability and adhesion characteristics, color saturation, and drying performance.

4.New Mechanical Platform

Perfect spray shape and precision of ink droplets are realized by controlling printhead height accurately.

The structure of the roll group and assembly process have been optimized precisely, which ensures the roll-to-roll stability of paper running in the state of high speed up to 150m/min.

Unique And Reliable Synchronous control technology at High Speed.

The encoder combined with blue-ray technology supports The encoder combined with blue-ray technology supports the paper moving, which improves effectively to ensure registration accuracy and uniformity of color tones.

Brand-New Closed-Loop Tension Control System

Real-time tension compensation and digital control are realized during running, which fully guarantees the stability of moving paper and thus greatly enhances the stability of high-speed printing.

5.New Inkjet Screening Technology

Based on the "Founder inkjet halftone screening technology" dedicated to Founder inkjet equipment, combined with the characteristics of 1200dpi printhead and permeability and adhesion of ink on paper, the multi-bit depth variable ink-droplet screening technology was specifically designed to intelligently distribute the ink-droplet size and configure automatically best screening mode.

This screening technology has presented better printing quality with less ink amount, which reduces the drying requirements of pages with large ink amounts and thus effectively improves the printing stability of large-ink pages at high speed.

6.Founder Color Tools Color Management Technology (Inkjet Version)

Combined with the characteristics of inkjet technology a number of technological innovations have been broken through, such as workflow color management technology, Al color separation control technology, etc. These technologies not only realize the one-key operation of linear calibration of industrial inkjet printing but also significantly improve the brightness and smoothness of the output image.

By improving the algorithm of color and screening, extremely high light dots can be shown on the paper, so that the gradient level can be optimized.

•Professional Digital Printing Proces.

Large Chinese font support is well compatible with various software file formats, which realizes the workflow processing of file standardization. imposition& composition, color management, as well as RIP output printing. The process protects the visualization, safety, efficiency and convenience.

ElecRoc effectively intearates customers' existing production equipment, and meets the applications in the fields of government printing, book POD, business printing, digital printing, brochures, and others.

•Core Technology Of Color And RIP To Ensure Quality

The strong RIP cluster control ability of "ElecRoc" ensures the processing efficiency of massive files, which becomes the basis of full-speed printing.

The optimized conversion from color to gray image, as a core technology, is developed to realize the high consistency between gray image and color manuscript in the reduction of gradation level details.

Text edge optimization technology can effectively eliminate the jagged edges of text, thereby achieving the best printing effect of texts.

Text processing technology applied on outlines shows advantages on maintaining outlines smooth and slight to guarantee text quality.

•Full-Featured Inkjet Imposition And Folding Function

The function provides flexible and diverse imposition methods for books and periodicals printing, and at the same time supports perfect bound, saddle stitch, sewing, and other binding methods. That means one production line can be applied to different business types of customers to enhance production efficiency.

It also provides a variety of intelligent maks, including one-dimensional codes and two-dimensional codes, which can effectively meet customers' identification needs for production marks of traditional and digital post-press equipment, and make full use of existing post-press equipment to improve production efficiency.

•Professional Digital Printing Proces.

Large Chinese font support is well compatible with various software file formats, which realizes the workflow processing of file standardization. imposition& composition, color management, as well as RIP output printing. The process protects the visualization, safety, efficiency and convenience.

ElecRoc effectively intearates customers' existing production equipment, and meets the applications in the fields of government printing, book POD, business printing, digital printing, brochures, and others.

•Core Technology Of Color And RIP To Ensure Quality

The strong RIP cluster control ability of "ElecRoc" ensures the processing efficiency of massive files, which becomes the basis of full-speed printing.

The optimized conversion from color to gray image, as a core technology, is developed to realize the high consistency between gray image and color manuscript in the reduction of gradation level details.

Text edge optimization technology can effectively eliminate the jagged edges of text, thereby achieving the best printing effect of texts.

Text processing technology applied on outlines shows advantages on maintaining outlines smooth and slight to guarantee text quality.

•Full-Featured Inkjet Imposition And Folding Function

The function provides flexible and diverse imposition methods for books and periodicals printing, and at the same time supports perfect bound, saddle stitch, sewing, and other binding methods. That means one production line can be applied to different business types of customers to enhance production efficiency.

It also provides a variety of intelligent maks, including one-dimensional codes and two-dimensional codes, which can effectively meet customers' identification needs for production marks of traditional and digital post-press equipment, and make full use of existing post-press equipment to improve production efficiency.

LQ-MD 5600HD Roll-to-cut Deployment Diagram

Perfect Localized And Fast Service Support.

The UPGJET's localized professional team provides fast and high-quality services including system maintenance, repair, upgrade, etc. Localized production of whole machines guarantees a fast supply of accessories and actual production.

Remote Diagnosis

Combining with the market demand and the actual needs of customers, UPGJET has developed a remote diagnosis platform for inkjet equipment. With the lnternet as well as real-time data analysis and processing technology, the platform can reduce downtime of equipment, and improve the efficiency of after-sales service, thereby providing faster, more accurate and more reliable service

LQ-MD 5600HD Roll-to-cut Deployment Diagram

Perfect Localized And Fast Service Support.

The UPGJET's localized professional team provides fast and high-quality services including system maintenance, repair, upgrade, etc. Localized production of whole machines guarantees a fast supply of accessories and actual production.

Remote Diagnosis

Combining with the market demand and the actual needs of customers, UPGJET has developed a remote diagnosis platform for inkjet equipment. With the lnternet as well as real-time data analysis and processing technology, the platform can reduce downtime of equipment, and improve the efficiency of after-sales service, thereby providing faster, more accurate and more reliable service