| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

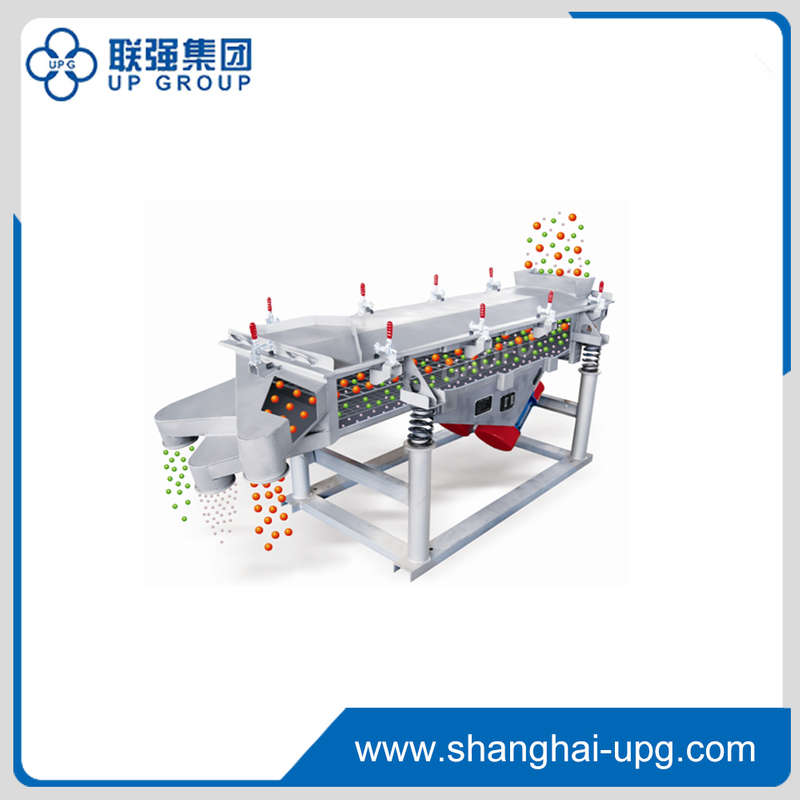

LQ-SZF

UPG

LQ-SZF series linear vibrating screen use vibration motor as vibration source, the materials is rosed and moved in the straight at the same time. The materials are entered into entrance equality, and then go through screen to create the materials with different sizes, which was discharged, from different gates. It is suitable for low consuming, high output, and simple structure, easily maintain all closed structure, no powder dispersed, automobile discharged.

Applicable materials: Use for selection and classification of powdery and granular materials, widely used in plastic, abrasive, chemical, pharmaceutical, building materials, food, carbon, chemical and other industries.

LQ-SZF series linear vibrating screen use vibration motor as vibration source, the materials is rosed and moved in the straight at the same time. The materials are entered into entrance equality, and then go through screen to create the materials with different sizes, which was discharged, from different gates. It is suitable for low consuming, high output, and simple structure, easily maintain all closed structure, no powder dispersed, automobile discharged.

Applicable materials: Use for selection and classification of powdery and granular materials, widely used in plastic, abrasive, chemical, pharmaceutical, building materials, food, carbon, chemical and other industries.

| Model | LQ-SZF-520 | LQ-SZF-525 | LQ-SZF-1020 | LQ-SZF-1025 | LQ-SZF-1030 | ||||||

| Size(mm) | 500×2000 | 500×2500 | 1000×2000 | 1000×2500 | 1000×3000 | ||||||

| Material Granularity | 0.074~10(mm) | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 ×(0.4~0.75) | 2 ×(0.4~1.1) | 2× (1.1~1.5) | ||||||||

| Model | LQ-SZF-1040 | LQ-SZF-1235 | LQ-SZF-1250 | LQ-SZF-1535 | LQ-SZF-1560 | ||||||

| Size(mm) | 1000 ×4000 | 1200 ×3500 | 1200 ×5000 | 1500 ×3500 | 1500×6000 | ||||||

| Material Granularity | 0.074~10 | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 ×(1.1~1.5) | 2 ×(1.1~2.2) | 2 × (2.2~3.7) | ||||||||

| Model | LQ-SZF-1845 | LQ-SZF-2050 | LQ-SZF-2260 | ||||||||

| Size(mm) | 1800×4500 | 2000×5000 | 2200×6000 | ||||||||

| Material Granularity | 0.074~15(mm) | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 × (2.2~3.7) | ||||||||||

| Model | LQ-SZF-520 | LQ-SZF-525 | LQ-SZF-1020 | LQ-SZF-1025 | LQ-SZF-1030 | ||||||

| Size(mm) | 500×2000 | 500×2500 | 1000×2000 | 1000×2500 | 1000×3000 | ||||||

| Material Granularity | 0.074~10(mm) | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 ×(0.4~0.75) | 2 ×(0.4~1.1) | 2× (1.1~1.5) | ||||||||

| Model | LQ-SZF-1040 | LQ-SZF-1235 | LQ-SZF-1250 | LQ-SZF-1535 | LQ-SZF-1560 | ||||||

| Size(mm) | 1000 ×4000 | 1200 ×3500 | 1200 ×5000 | 1500 ×3500 | 1500×6000 | ||||||

| Material Granularity | 0.074~10 | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 ×(1.1~1.5) | 2 ×(1.1~2.2) | 2 × (2.2~3.7) | ||||||||

| Model | LQ-SZF-1845 | LQ-SZF-2050 | LQ-SZF-2260 | ||||||||

| Size(mm) | 1800×4500 | 2000×5000 | 2200×6000 | ||||||||

| Material Granularity | 0.074~15(mm) | ||||||||||

| Screen Surface Lean Angle | 0°~7° | ||||||||||

| Amplitude(mm) | 4~10 | ||||||||||

| Layers(s) | 1~6 | ||||||||||

| Power(kw) | 2 × (2.2~3.7) | ||||||||||