| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

UPG

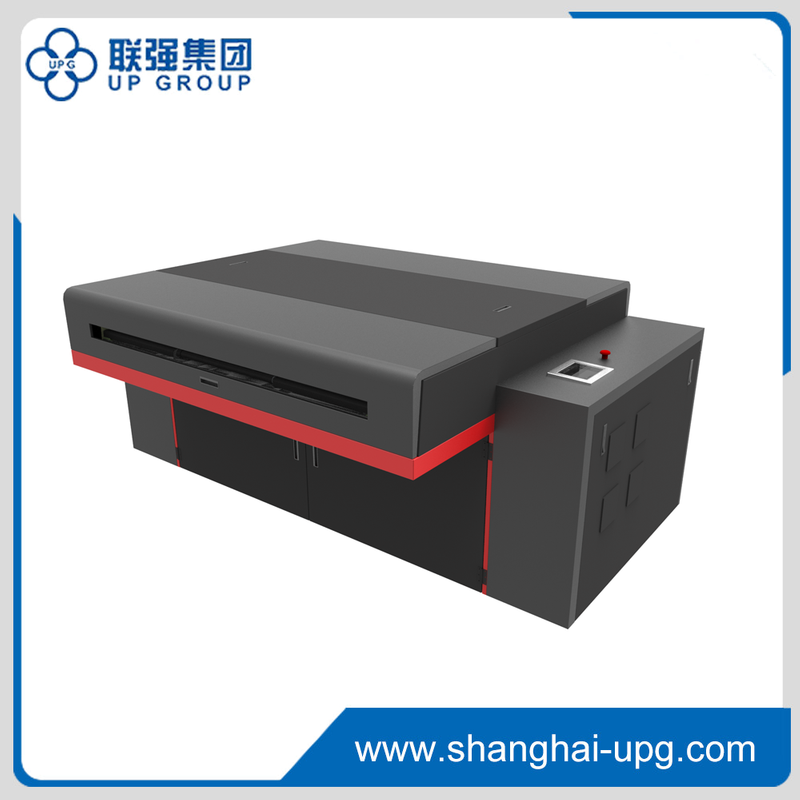

LQ1450 series of CTP plate setters utilize advanced thermal image technology, which realize day light operation.

Highly stable lasers and optical system produce sharp printing dot, capable of reproducing 1%-99% dot at 300lpi. The end result to high quality and accurate printing. It is easy to maintain.

External drum configuration keeps the plate direction consistent on drum the same during plate making and on press, which ensures the highest consistency during printing and plate making.

Automated in – line punch systems are accurate and economic.

Marble platform provides the best stability in variety of ambient temperatures.

Fully automated drum balancing system ensures smooth& high-speed operation of any plate size and thickness.

Two tiers, separate loading and unloading allows continuous plate load, front or back plate ejection.

Independent dust control unit to ensure cleanliness of laser unit and quality of plate setting.

Open and intuitive user interface with touch screen allows easy operation.

LQ1450 series of CTP plate setters utilize advanced thermal image technology, which realize day light operation.

Highly stable lasers and optical system produce sharp printing dot, capable of reproducing 1%-99% dot at 300lpi. The end result to high quality and accurate printing. It is easy to maintain.

External drum configuration keeps the plate direction consistent on drum the same during plate making and on press, which ensures the highest consistency during printing and plate making.

Automated in – line punch systems are accurate and economic.

Marble platform provides the best stability in variety of ambient temperatures.

Fully automated drum balancing system ensures smooth& high-speed operation of any plate size and thickness.

Two tiers, separate loading and unloading allows continuous plate load, front or back plate ejection.

Independent dust control unit to ensure cleanliness of laser unit and quality of plate setting.

Open and intuitive user interface with touch screen allows easy operation.

| Model | DX1450T-I | DX1450T-II | DX1450U-I | DX1450U-II |

| Laser system | 830nm LD, 64 channels | 830nm LD, 96 channels | 405nm LD, 64 channels | 405nm LD, 96 channels |

| Resolution | 2400dpi | |||

| Output speed | 18p/h(1450mm*1150mm) | 23p/h(1450mm*1150mm) | 18p/h(1450mm*1150mm) | 23p/h(1450mm*1150mm) |

| Exposure Structure | External drum | |||

| Plate size | Max.1450mm*1150mm; Min.650 mm*550mm | |||

| Plate thickness | Thermal(830nm)0.15~0.4mm | UV(405nm)0.15~0.4mm | ||

| Max hanged line | 300lpi | |||

| FM dots output | 20μm | |||

| Repeatability | ±0.005mm | |||

| Power supply | Three-phase 380V AC/50Hz-60HZ 6KW | |||

External dimension | L*W*H=2740mm*1750mm*1350mm 2000kg | |||

| Model | DX1450T-I | DX1450T-II | DX1450U-I | DX1450U-II |

| Laser system | 830nm LD, 64 channels | 830nm LD, 96 channels | 405nm LD, 64 channels | 405nm LD, 96 channels |

| Resolution | 2400dpi | |||

| Output speed | 18p/h(1450mm*1150mm) | 23p/h(1450mm*1150mm) | 18p/h(1450mm*1150mm) | 23p/h(1450mm*1150mm) |

| Exposure Structure | External drum | |||

| Plate size | Max.1450mm*1150mm; Min.650 mm*550mm | |||

| Plate thickness | Thermal(830nm)0.15~0.4mm | UV(405nm)0.15~0.4mm | ||

| Max hanged line | 300lpi | |||

| FM dots output | 20μm | |||

| Repeatability | ±0.005mm | |||

| Power supply | Three-phase 380V AC/50Hz-60HZ 6KW | |||

External dimension | L*W*H=2740mm*1750mm*1350mm 2000kg | |||