| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-ZBNB-D

UPG

Description:

LQ-ZB-D12S paper cup machine is improved based on the normal chain driving type. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. It is an ideal equipment for producing drinking cups, market cups, coffee cups, advertising cups, etc. It is widely used for hot drink and beverage.

If you need double pe-coated paper cups or paper gram higher 250g/m2, we recommend you to use Ultrasonic paper cup machine. It can produce single pe coated paper cups and double pe-coated paper cups.

Advantage and improvement:

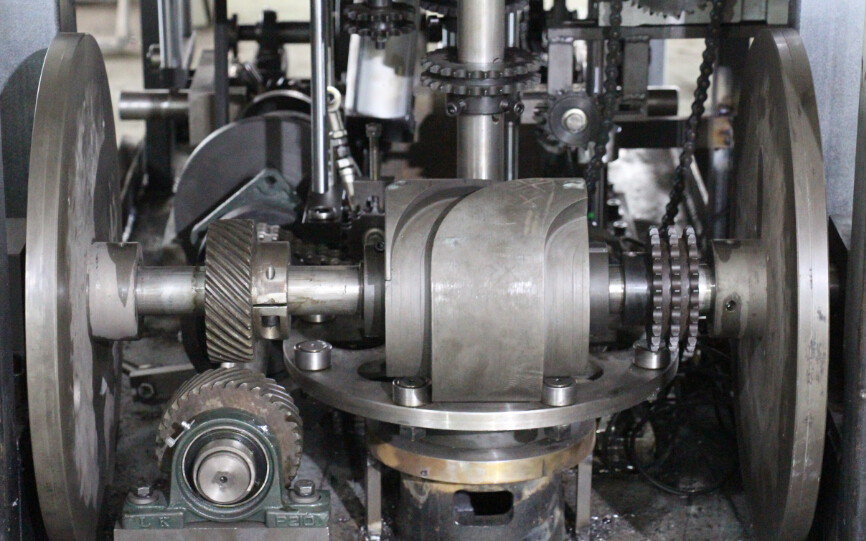

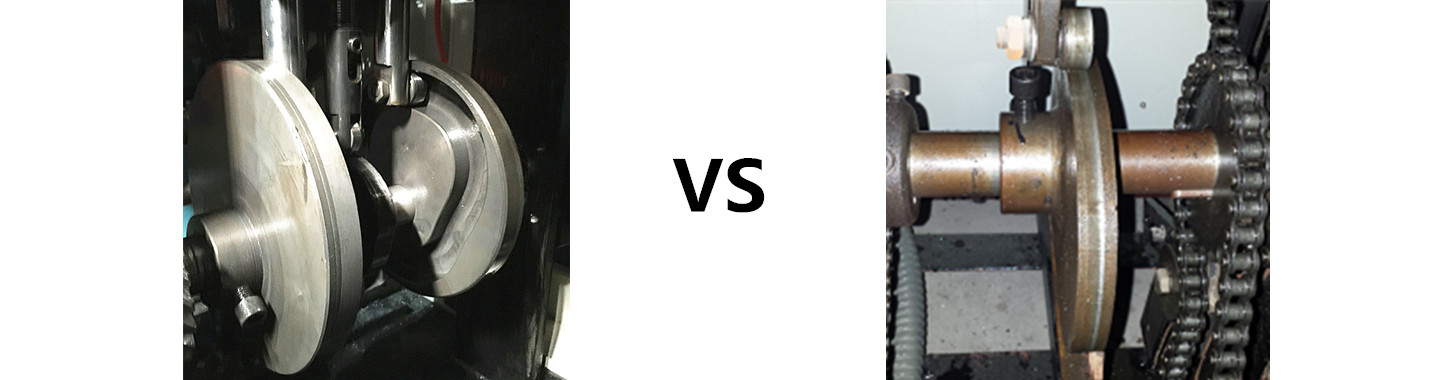

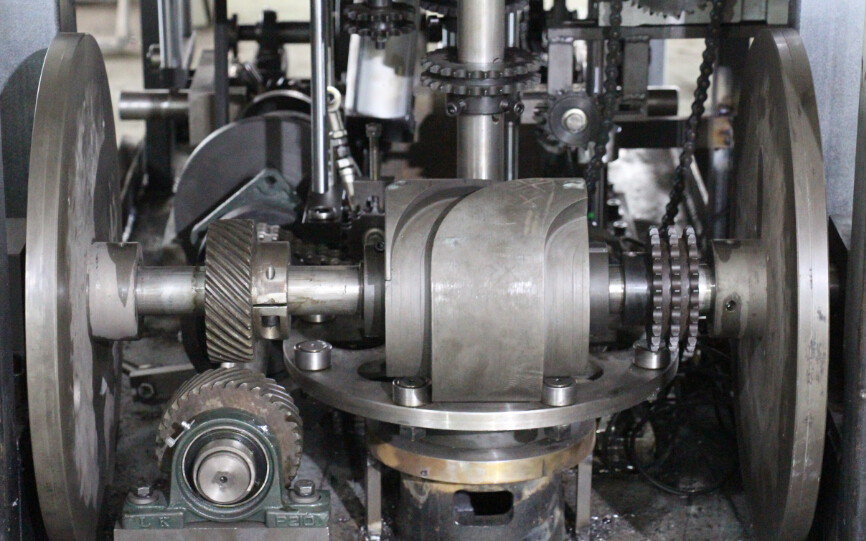

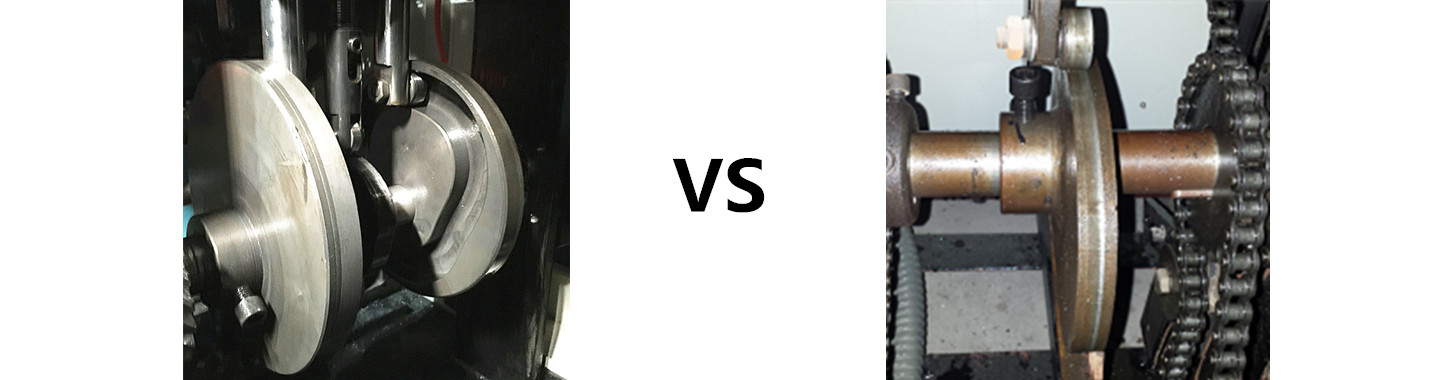

1.Use Gear Driving System instead of chain, more stable running and speed up.

2.Use open cam driving system.

3.100 type speed reducer is used instead 80 type.

The speed reducer and the gear box are very important to the machine.They control the whole machine,if there are some problems with these two parts,then,you have to change the gear box and speed reducer.In this case,the machine should be taken apart,because they are inside the machine.It takes much time,and sometimes you cannot install the machine correctly.So it is necessary yo use better gear box and speed reducer.

4. New design knurling wheel is used to guarantee the even pressure and better bottom sealing.

5. Cup folding parts is controlled by three separate cams, and each folding clip can be adjusted by itself.

6. We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.

7.Change the Ø25 normal steel shaft to Ø30 imported steel shaft to be sttrengthened,longer life and more stable.

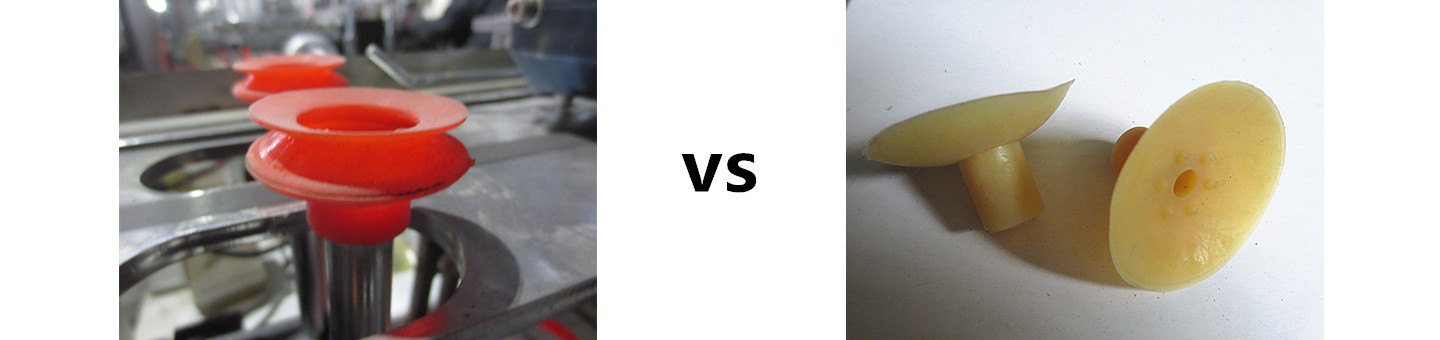

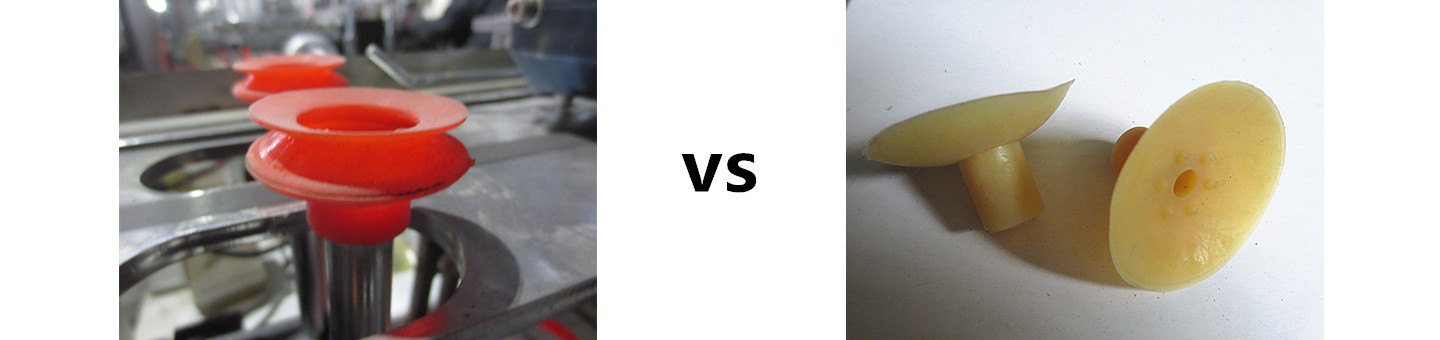

8. Organ type sucker is used for cup fan sucked to guarantee powerful sucking and more successful. The life is much longer than normal sucker.

Description:

LQ-ZB-D12S paper cup machine is improved based on the normal chain driving type. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. It is an ideal equipment for producing drinking cups, market cups, coffee cups, advertising cups, etc. It is widely used for hot drink and beverage.

If you need double pe-coated paper cups or paper gram higher 250g/m2, we recommend you to use Ultrasonic paper cup machine. It can produce single pe coated paper cups and double pe-coated paper cups.

Advantage and improvement:

1.Use Gear Driving System instead of chain, more stable running and speed up.

2.Use open cam driving system.

3.100 type speed reducer is used instead 80 type.

The speed reducer and the gear box are very important to the machine.They control the whole machine,if there are some problems with these two parts,then,you have to change the gear box and speed reducer.In this case,the machine should be taken apart,because they are inside the machine.It takes much time,and sometimes you cannot install the machine correctly.So it is necessary yo use better gear box and speed reducer.

4. New design knurling wheel is used to guarantee the even pressure and better bottom sealing.

5. Cup folding parts is controlled by three separate cams, and each folding clip can be adjusted by itself.

6. We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.

7.Change the Ø25 normal steel shaft to Ø30 imported steel shaft to be sttrengthened,longer life and more stable.

8. Organ type sucker is used for cup fan sucked to guarantee powerful sucking and more successful. The life is much longer than normal sucker.

Type: | LQ-ZBNB-D |

Cup size: | 3-12oz(different size mold exchanged) |

Suitable paper material: | 150-380g/m2(single or double PE-coated paper) |

Capacity: | 40-50pcs/min |

Power source:: | 220V、380V 50HZ(please inform us your power in advanced) |

Total power: | 4KW |

Weight: | 2000KG |

Package size: | 2500 x 1500 x 1700 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A:Top diameter: Min 45mm---Max 90mm B: Bottom diameter Min 35mm---Max 75mm C: Total height Min 30mm---Max 115mm D: Bottom knurling depth Min 4mm---Max 12mm E: Rim diameter Usually Φ2.5---Φ3 |

Type: | LQ-ZBNB-D |

Cup size: | 3-12oz(different size mold exchanged) |

Suitable paper material: | 150-380g/m2(single or double PE-coated paper) |

Capacity: | 40-50pcs/min |

Power source:: | 220V、380V 50HZ(please inform us your power in advanced) |

Total power: | 4KW |

Weight: | 2000KG |

Package size: | 2500 x 1500 x 1700 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A:Top diameter: Min 45mm---Max 90mm B: Bottom diameter Min 35mm---Max 75mm C: Total height Min 30mm---Max 115mm D: Bottom knurling depth Min 4mm---Max 12mm E: Rim diameter Usually Φ2.5---Φ3 |