| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

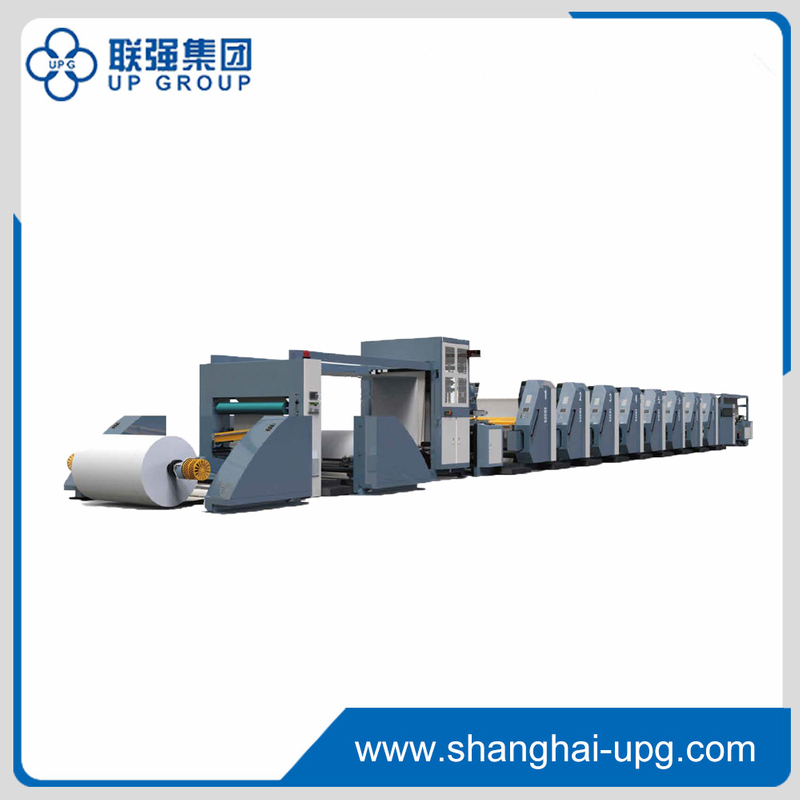

LQ-MD 1800

UPG

LQ-MD1800

Product Description

Upper web passing design makes more efficiency works with faster printing speed.

Individual temperature control in each upper unit. Improves drying capacity during high speed, and plate-drying issue with water-based ink.

Servo system transmission control to ensure machine stability.

Long-distance diagnosis function with quick troubleshooting, equipment status in-time reporting with lower waste in material and save cost.

None-stop auto unwinder and rewinder.

Unique design to solve the bumping marks caused by plate gap, hydraulic locking device to lock down the plate cylinder and anilox.

Multi-drying methods selection: Steam/ natural gas or electric heating.

More Optimized functions: Auto web passing/ Auto cleaning etc.

Main Control System

PLC central integrated control system.

Automatic monitoring the performance of the whole control system before operation.

Various parameters setting, operation data checking and tension control checking in the working process.

Automatic operation control of pneumatic components.

Standard sealed electric cabinet, equipped with fan circulation cooling device, and grouped by functions.

Equipped with LED power supply voltage, frequency, motor current and other instruments.

The whole system has perfect protection and anti-jamming measures.

All motor drive inverter specifications are the same as those of the corresponding motor.

Product Description

Upper web passing design makes more efficiency works with faster printing speed.

Individual temperature control in each upper unit. Improves drying capacity during high speed, and plate-drying issue with water-based ink.

Servo system transmission control to ensure machine stability.

Long-distance diagnosis function with quick troubleshooting, equipment status in-time reporting with lower waste in material and save cost.

None-stop auto unwinder and rewinder.

Unique design to solve the bumping marks caused by plate gap, hydraulic locking device to lock down the plate cylinder and anilox.

Multi-drying methods selection: Steam/ natural gas or electric heating.

More Optimized functions: Auto web passing/ Auto cleaning etc.

Main Control System

PLC central integrated control system.

Automatic monitoring the performance of the whole control system before operation.

Various parameters setting, operation data checking and tension control checking in the working process.

Automatic operation control of pneumatic components.

Standard sealed electric cabinet, equipped with fan circulation cooling device, and grouped by functions.

Equipped with LED power supply voltage, frequency, motor current and other instruments.

The whole system has perfect protection and anti-jamming measures.

All motor drive inverter specifications are the same as those of the corresponding motor.

Maximum Paper Width | 1820mm |

Maximum Printing Width | 1760mm |

Printing Repeat | 600-1600mm/ 800-2000mm |

Maximum Unwinder Diameter | 1524mm |

Maximum Mechanical Speed | 260m/min |

Plate Thickness | 1.7mm |

Tape Thickness | 0.5mm |

Substrate | 100-300gsm |

Control | Chinese/ English |

Air Pressure | 8kg |

Power Requirement | 380v, AC±10%, 3ph, 50Hz |

Tension Control Range | 10-60kg |

Tension Control Tolerance | ±2kg |

Ink Supply | Automatic Circulate |

Anilox | Size TBD |

Plate Cylinder | Size TBD |

Dryer | Gas drying or electric heating and drying |

Dryer Temperature | 120℃ |

Main Drive | Servo Motors control |

Printing Board | Casting Board-make the board more stable |

Automatic Registration system | Automatic Registration system save material waste |

Maximum Paper Width | 1820mm |

Maximum Printing Width | 1760mm |

Printing Repeat | 600-1600mm/ 800-2000mm |

Maximum Unwinder Diameter | 1524mm |

Maximum Mechanical Speed | 260m/min |

Plate Thickness | 1.7mm |

Tape Thickness | 0.5mm |

Substrate | 100-300gsm |

Control | Chinese/ English |

Air Pressure | 8kg |

Power Requirement | 380v, AC±10%, 3ph, 50Hz |

Tension Control Range | 10-60kg |

Tension Control Tolerance | ±2kg |

Ink Supply | Automatic Circulate |

Anilox | Size TBD |

Plate Cylinder | Size TBD |

Dryer | Gas drying or electric heating and drying |

Dryer Temperature | 120℃ |

Main Drive | Servo Motors control |

Printing Board | Casting Board-make the board more stable |

Automatic Registration system | Automatic Registration system save material waste |

Motion Control System | YASKAWA/ B&R |

PLC & SERVO | YASKAWA/ B&R |

Web Guide | E+L/ BST Germany |

Tension Control | Mitsubishi |

Vector transducer (Rewinder) | YASKAWA/INOVANCE |

Auto Lubrication | Bljur |

Middle Relay | Weidmuller |

Contactor | Siemens/ Schneider |

Breaker | Siemens/ Schneider |

Control Display | PRO-FACE |

Control Buttons | APT |

Plug | WEIPU |

Photoelectric Sensor | BANNER |

Pneumatic parts | WEIHE/ Air Tec |

Motion Control System | YASKAWA/ B&R |

PLC & SERVO | YASKAWA/ B&R |

Web Guide | E+L/ BST Germany |

Tension Control | Mitsubishi |

Vector transducer (Rewinder) | YASKAWA/INOVANCE |

Auto Lubrication | Bljur |

Middle Relay | Weidmuller |

Contactor | Siemens/ Schneider |

Breaker | Siemens/ Schneider |

Control Display | PRO-FACE |

Control Buttons | APT |

Plug | WEIPU |

Photoelectric Sensor | BANNER |

Pneumatic parts | WEIHE/ Air Tec |