| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD LC250

UPG

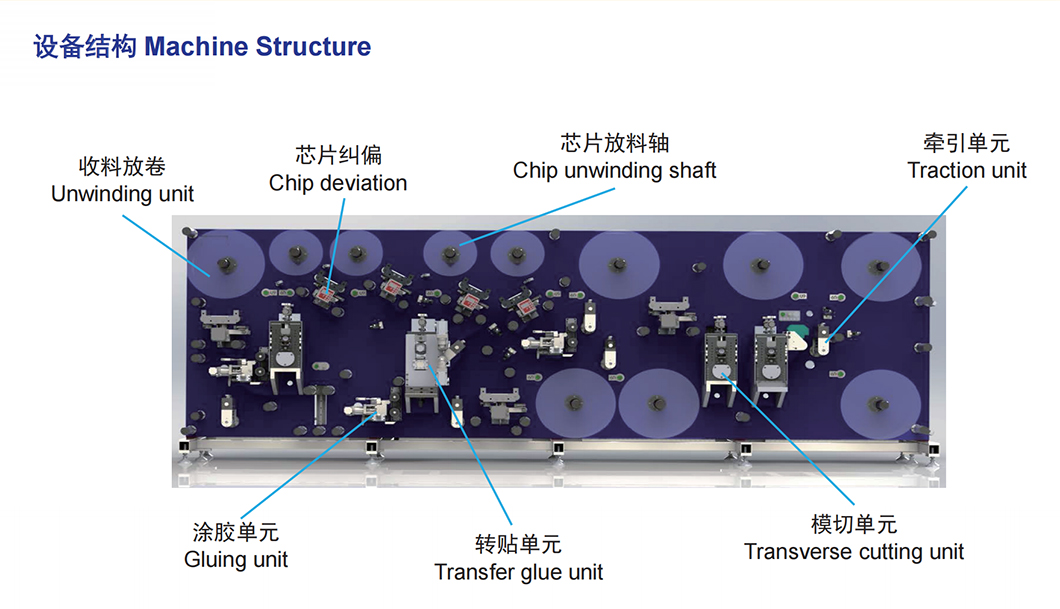

Machine Structure

1.Auxiliary Shaft

Automatic tension control: roll diameter could be self-adaptable, which is set in the function of tension-control, with easy operation.

External auto-deviation device: by supersonic wave, it could respond to the location of the material belt, to ensure location consistency when materials are not even.

2.Cutting& Transfer glue unit

Inlay cutters: free-match different blade space, such as two, three, four, six, twelve and so on, which is flexible to match up and easy to install or uninstall.

3.Gluing Unit

Before this machine starts, firstly, the distance air-cylinder is open and then the gluing head is near to the materials to be printed, Secondly, gluing air cylinder is also open then machine starts to run, which could effectively decrease surplus-glue to be left over when machine begins.

Machine structure

Application

This machine could realize RFID tag more layer of materials to be laminated, which are applicable for different ticket-cards in different industry, such as garment, electronic, Medical Treatment and Public Health, logistic, etc.

Parameters

| Model | LQ-MD LC250 |

| Running speed | 100m/min |

| The material width | 250mm |

| Roll diameter | 600mm |

| Roll weight | 30kg |

| Gluing width | 230mm |

| The min stepping distance for tag | 12-200mm |

| Cutting precision | ≤+0.3mm |

| Inlay paste precision | ≤+0.5mm |

| Double layer of laminating precision | ≤±0.4mm |

| Die-cutting precision | ≤±0.2mm |

| Power | AC380-400v 40kw |

| Overall size | 5600*1500*2300mm |

| Machine weight | 4000kg |

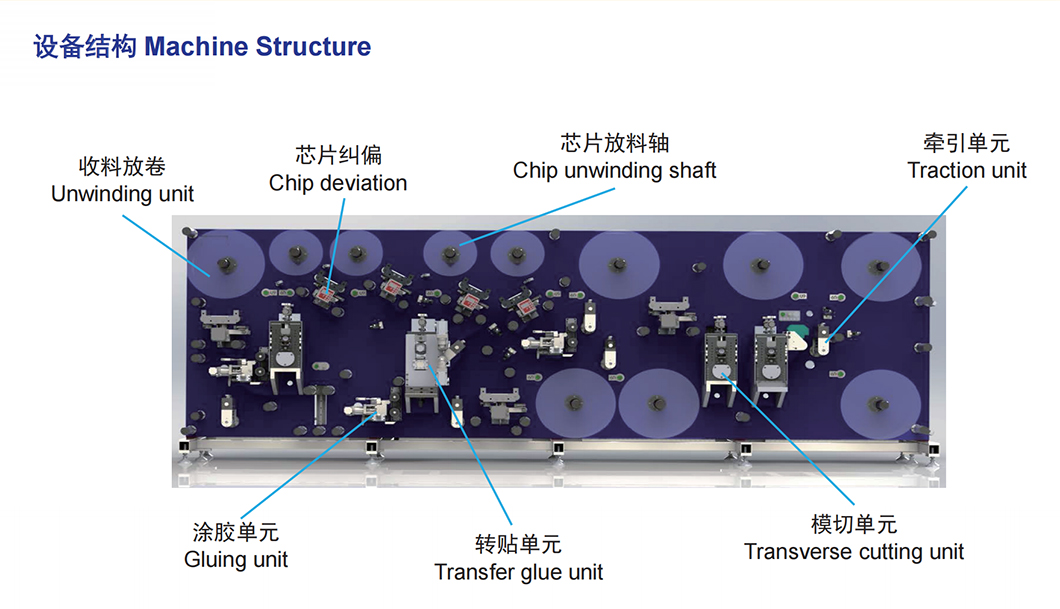

Machine Structure

1.Auxiliary Shaft

Automatic tension control: roll diameter could be self-adaptable, which is set in the function of tension-control, with easy operation.

External auto-deviation device: by supersonic wave, it could respond to the location of the material belt, to ensure location consistency when materials are not even.

2.Cutting& Transfer glue unit

Inlay cutters: free-match different blade space, such as two, three, four, six, twelve and so on, which is flexible to match up and easy to install or uninstall.

3.Gluing Unit

Before this machine starts, firstly, the distance air-cylinder is open and then the gluing head is near to the materials to be printed, Secondly, gluing air cylinder is also open then machine starts to run, which could effectively decrease surplus-glue to be left over when machine begins.

Machine structure

Application

This machine could realize RFID tag more layer of materials to be laminated, which are applicable for different ticket-cards in different industry, such as garment, electronic, Medical Treatment and Public Health, logistic, etc.

Parameters

| Model | LQ-MD LC250 |

| Running speed | 100m/min |

| The material width | 250mm |

| Roll diameter | 600mm |

| Roll weight | 30kg |

| Gluing width | 230mm |

| The min stepping distance for tag | 12-200mm |

| Cutting precision | ≤+0.3mm |

| Inlay paste precision | ≤+0.5mm |

| Double layer of laminating precision | ≤±0.4mm |

| Die-cutting precision | ≤±0.2mm |

| Power | AC380-400v 40kw |

| Overall size | 5600*1500*2300mm |

| Machine weight | 4000kg |