| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD H150

UPG

Features & Advantages

This machine has self-research&development control system and function orientation development.

With craft parameter-memory function, it is flexible to adjust the program.

Traction station adopts servo motor and the accessory shafts of unwinding& rewinding also use torque motor control, with higher synchronization and adjustable speed.

This equipment has intermittent feeding mode and continuous feeding mode, according to different read-write to be switched flexibly, which include counting-piece, counting-meter to be stop-emergency by alarm and auto-control machine to stop, according to different setting to control the machine pause or not.

Different unwinding shafts and rewinding shafts are equipped with one-key start or stop button so as that it is easy to exchange new job for the operator.

With safety protection function, it could realize auto-stop urgently if the operator is nearer to the dangerous zone, which could protect man-body in max extent. (option)

This machine has read& write& lock-code function, visual inspection for one dimension coding and also 2 dimension coding could be read, without any other equipment.

The defective productions carbon belt or kicking-waste platform is two options, more effective.

For some special materials, this equipment is equipped with supersonic-wave slitting function, whose extension is much stronger to meet different demands for different customers fully.

Whatever sheet material or roll material are all rewind automatically.

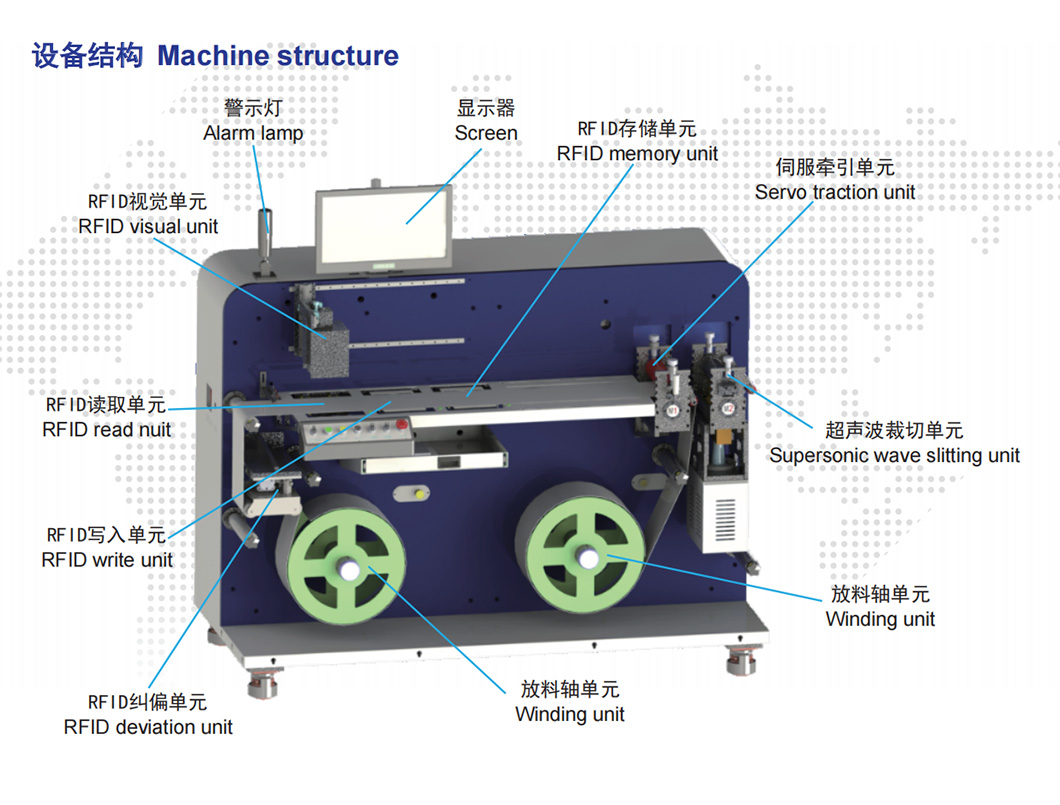

Machine structure

Application

Parameters

| Model | LQ-MD H150 |

| The platform running speed | 0-90m/min (according to different size of tag) |

| The tag width | max. 150mm |

| Roll diameter | max. 400mm |

| Tag jumping distance | >20 |

| EPC EPC writing-coding speed | 420 pcs/m (24 digit) |

| Running mode | Continuous |

| Applicable material | Roll of electronic tags (self-adhesive label, wet inlay) |

| Power | AC220V, 1kw |

| Overall size | 1800*850*1600mm |

| Weight | 700kg |

Features & Advantages

This machine has self-research&development control system and function orientation development.

With craft parameter-memory function, it is flexible to adjust the program.

Traction station adopts servo motor and the accessory shafts of unwinding& rewinding also use torque motor control, with higher synchronization and adjustable speed.

This equipment has intermittent feeding mode and continuous feeding mode, according to different read-write to be switched flexibly, which include counting-piece, counting-meter to be stop-emergency by alarm and auto-control machine to stop, according to different setting to control the machine pause or not.

Different unwinding shafts and rewinding shafts are equipped with one-key start or stop button so as that it is easy to exchange new job for the operator.

With safety protection function, it could realize auto-stop urgently if the operator is nearer to the dangerous zone, which could protect man-body in max extent. (option)

This machine has read& write& lock-code function, visual inspection for one dimension coding and also 2 dimension coding could be read, without any other equipment.

The defective productions carbon belt or kicking-waste platform is two options, more effective.

For some special materials, this equipment is equipped with supersonic-wave slitting function, whose extension is much stronger to meet different demands for different customers fully.

Whatever sheet material or roll material are all rewind automatically.

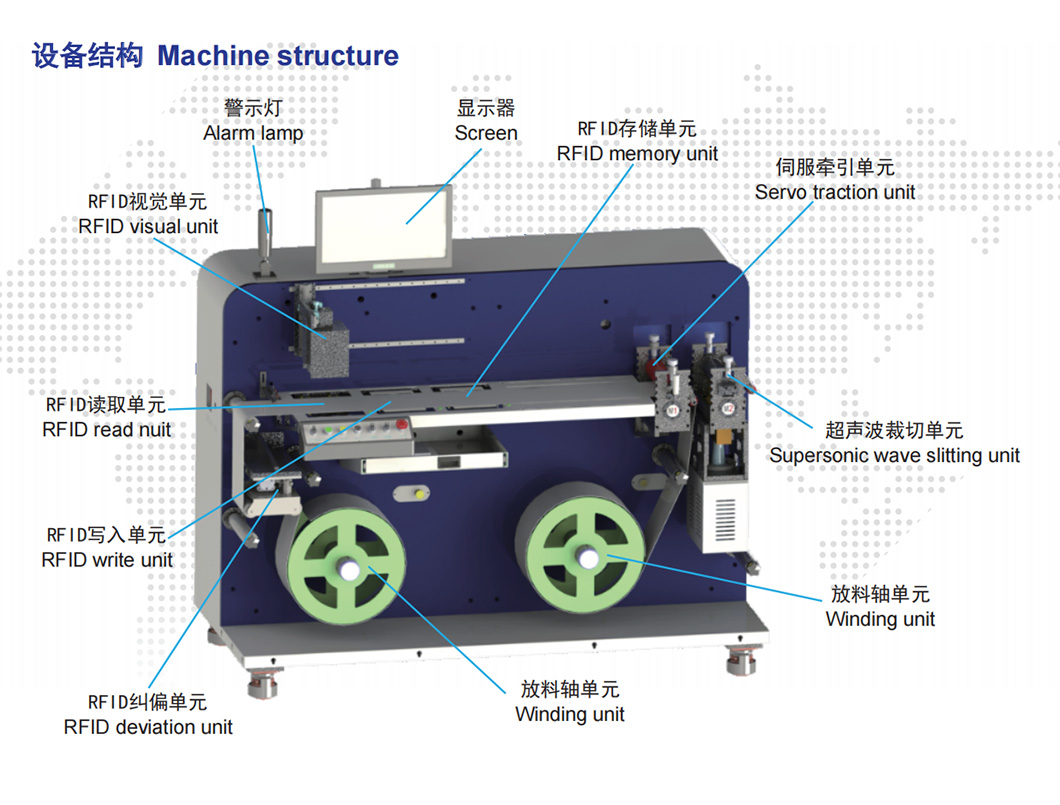

Machine structure

Application

Parameters

| Model | LQ-MD H150 |

| The platform running speed | 0-90m/min (according to different size of tag) |

| The tag width | max. 150mm |

| Roll diameter | max. 400mm |

| Tag jumping distance | >20 |

| EPC EPC writing-coding speed | 420 pcs/m (24 digit) |

| Running mode | Continuous |

| Applicable material | Roll of electronic tags (self-adhesive label, wet inlay) |

| Power | AC220V, 1kw |

| Overall size | 1800*850*1600mm |

| Weight | 700kg |