| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-WT-D

UPG

Description:

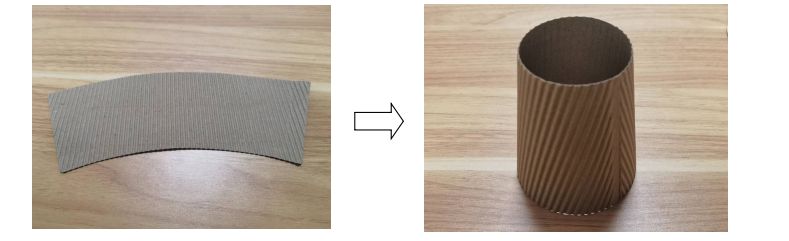

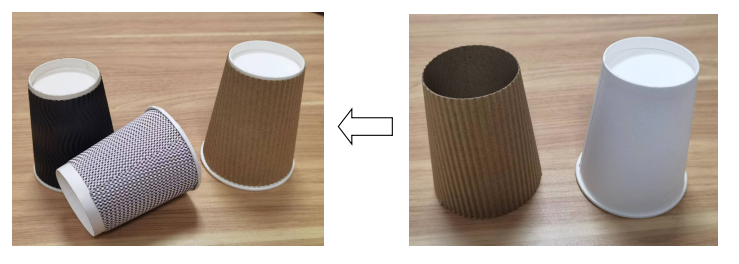

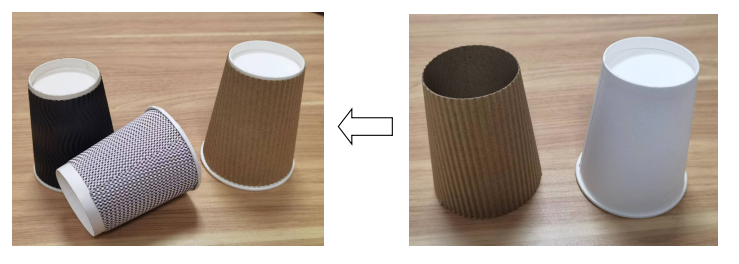

LQ-WT-D Double Wall Paper Cup Machine is a necessary accessory to Paper cup machine. It has advanced craft, reasonable design, automatic operation and other advantages. It can feed paper automatically, seal paper, extrude glue, unload cups, alarm trouble, count , etc.

New Main Features:

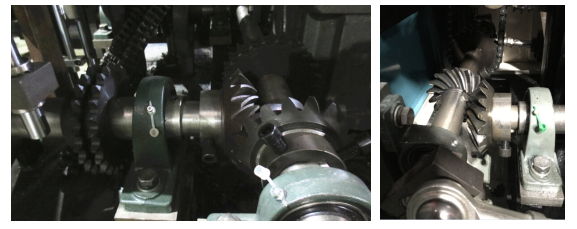

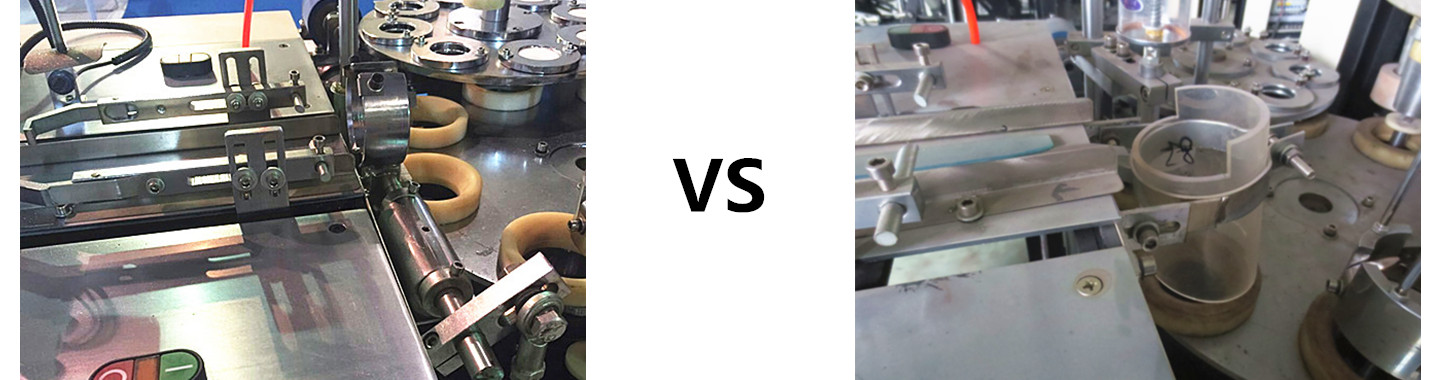

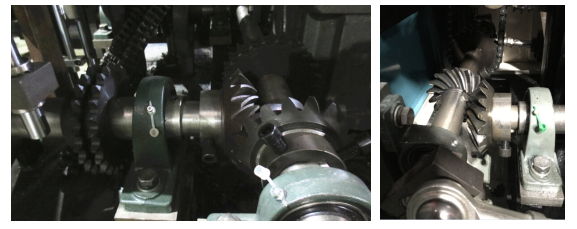

1.Use gear driving system instead of chain,more stable running and speed up.

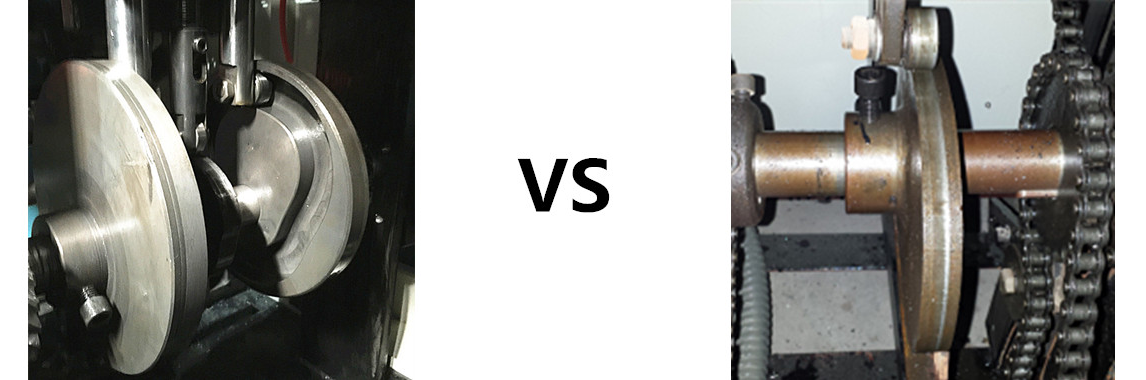

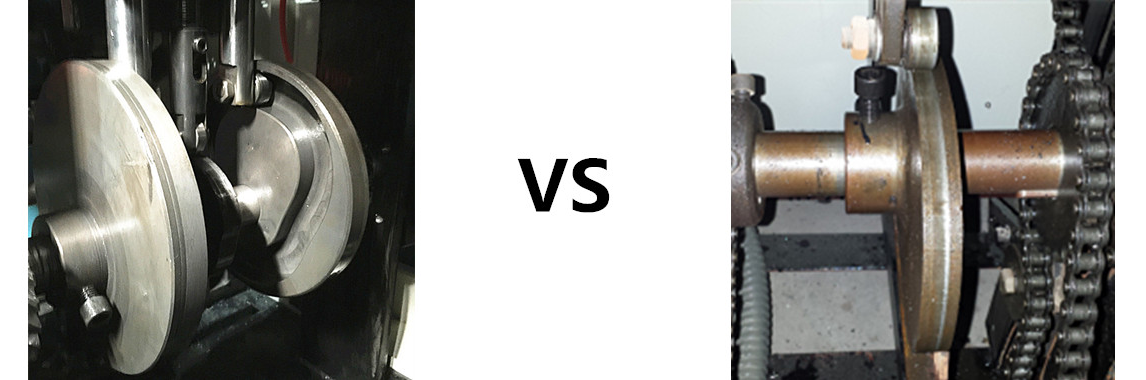

2.100 type speed reducer is used instead 80 type.

The speed reducer and the gear box are very important to the machine. They control the whole machine, if there are some problems with these two parts, then you have to change the gear box and speed reducer. In this case, the machine should be taken apart because they are inside the machine. It takes much time and sometimes you cannot install the machine correctly. So it is necessary to use better gear box and speed reducer.

3.Cup folding parts is controlled by three separate cams and each folding clip can be adjusted by itself.

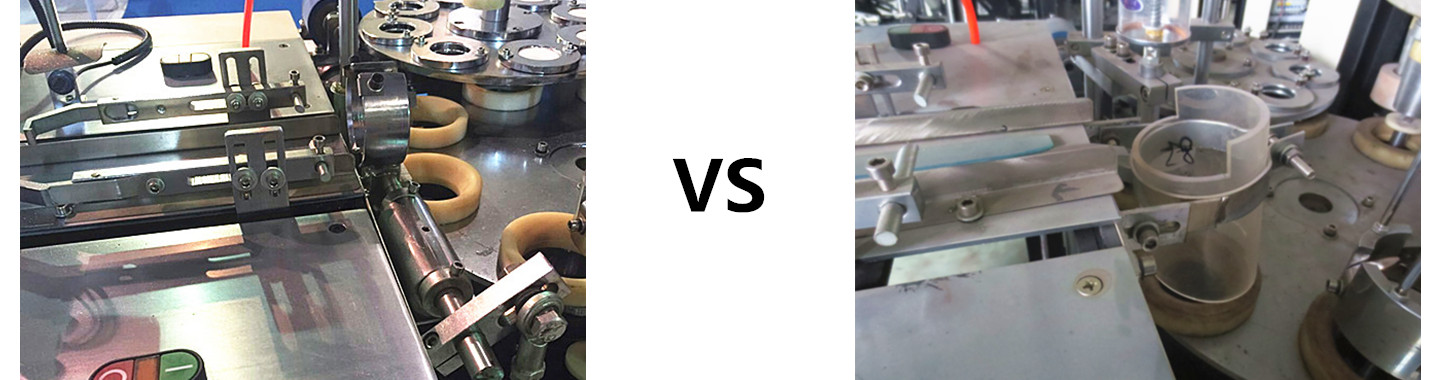

4.We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.

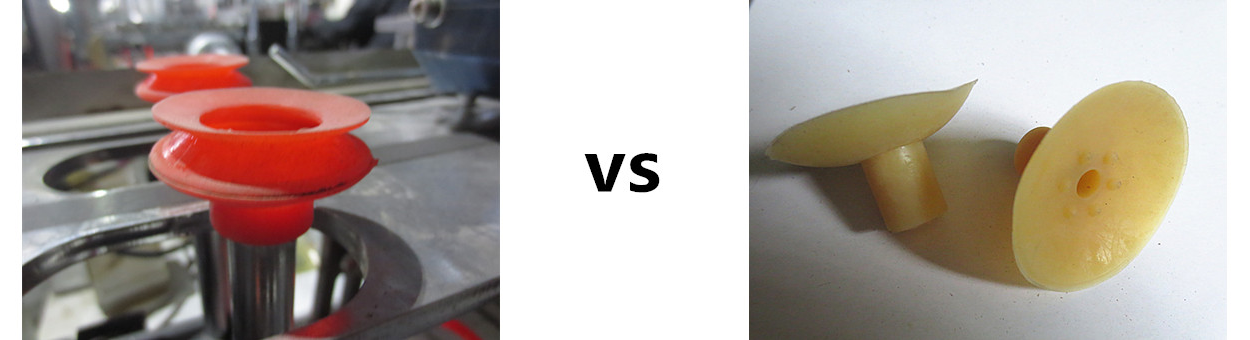

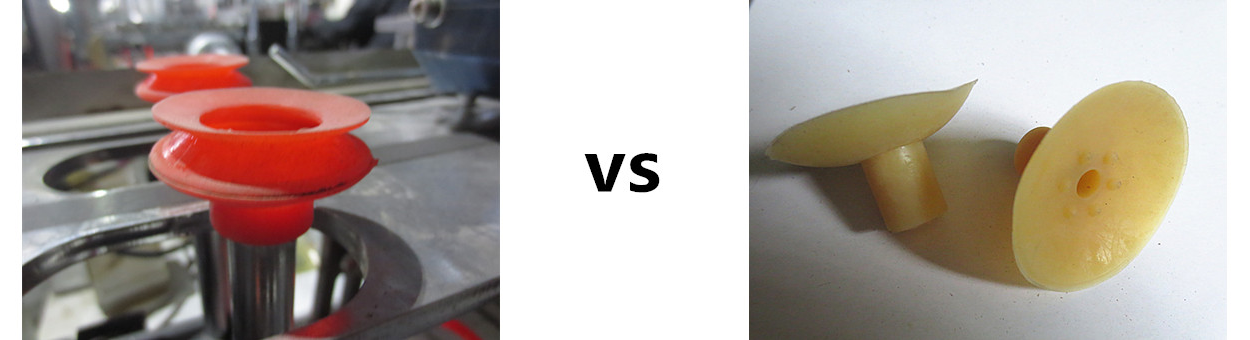

5.Organ type sucker is used for cup fan sucked to gaurantee powerful sucking and more successful. The life is much more longer than normal sucker.

Description:

LQ-WT-D Double Wall Paper Cup Machine is a necessary accessory to Paper cup machine. It has advanced craft, reasonable design, automatic operation and other advantages. It can feed paper automatically, seal paper, extrude glue, unload cups, alarm trouble, count , etc.

New Main Features:

1.Use gear driving system instead of chain,more stable running and speed up.

2.100 type speed reducer is used instead 80 type.

The speed reducer and the gear box are very important to the machine. They control the whole machine, if there are some problems with these two parts, then you have to change the gear box and speed reducer. In this case, the machine should be taken apart because they are inside the machine. It takes much time and sometimes you cannot install the machine correctly. So it is necessary to use better gear box and speed reducer.

3.Cup folding parts is controlled by three separate cams and each folding clip can be adjusted by itself.

4.We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.

5.Organ type sucker is used for cup fan sucked to gaurantee powerful sucking and more successful. The life is much more longer than normal sucker.

Cup size | Customized size (20, 25, 30, 35, 40, 50 ounce, etc.) |

Required paper | White plank paper of ash bottom (200-300 g/m²) |

Rated productivity | 50-60 pcs/min |

Electrical supply | 380V, 50Hz |

Total power | 3 kW |

Weight | 1000 kg |

Overall dimensions (L×W×H) | 2300 × 1500 × 1700 mm |

Cup size | Customized size (20, 25, 30, 35, 40, 50 ounce, etc.) |

Required paper | White plank paper of ash bottom (200-300 g/m²) |

Rated productivity | 50-60 pcs/min |

Electrical supply | 380V, 50Hz |

Total power | 3 kW |

Weight | 1000 kg |

Overall dimensions (L×W×H) | 2300 × 1500 × 1700 mm |