| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-ZSZB-D80S

UPG

Description

LQ-ZSZB-D80S Automatic Middle Speed Paper Bowl Forming Machine is the automatic environmental machine with multi-running positions. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. If you need double pe coated paper cups or paper gram higher 250kg, we recommend you to use Ultrasonic set, it can produce single pe coated paper cups and double pe coated paper cups.

Main Feature

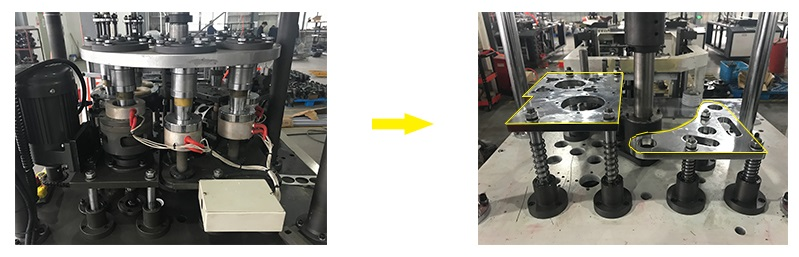

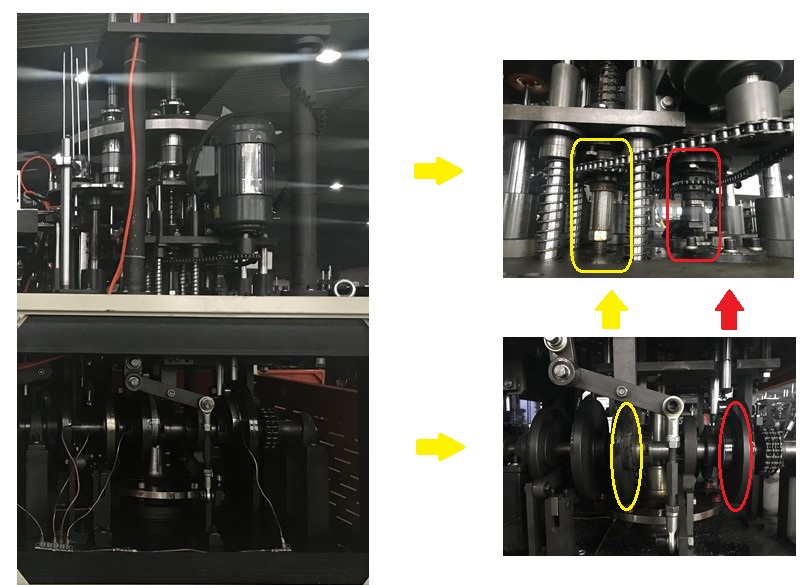

1. Use the vertical shaft system,open cam and gear driving system,automatic oil lubrication.

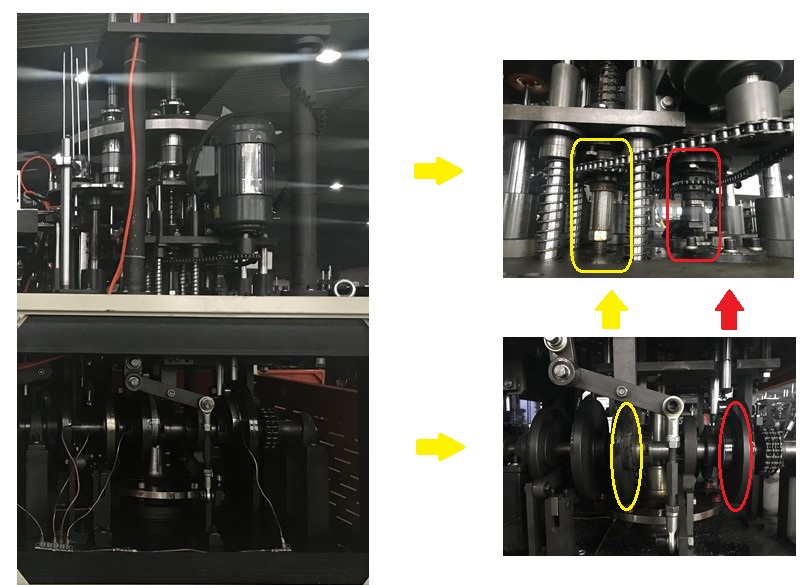

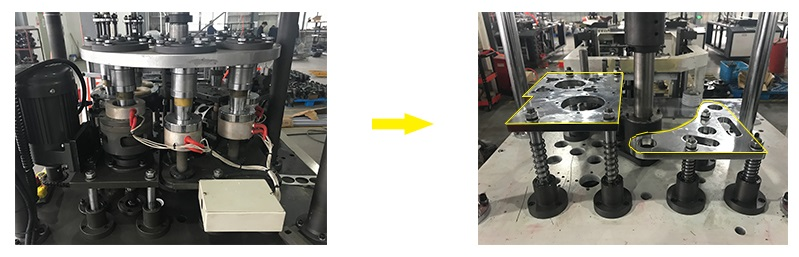

2. Forming section use separated cup bottom folding pre-heating section and knurling&curling section, reduce the machine loading and improve the balance of the whole section.

3. Use the individual cam to control the curling, knurling and pre-heating working position, more accurate and easy to operate.

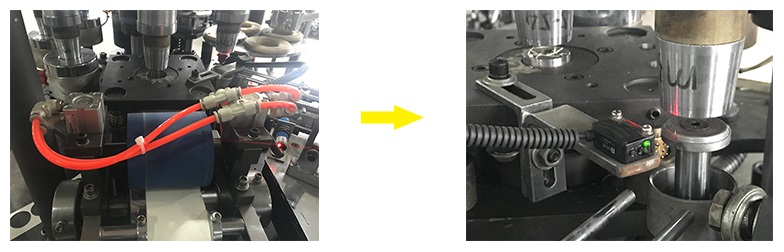

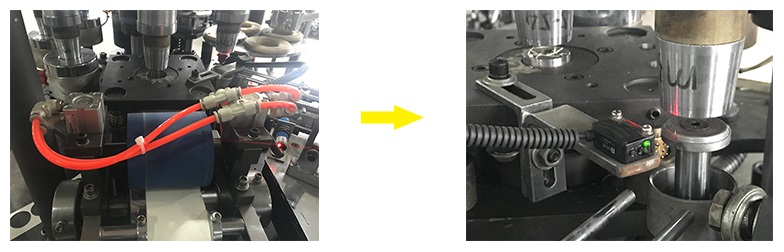

4. Use the Pneumatic regulating valve to the adjust bottom paper feeding instead of the bottom feeding plate, install the sensor to check bottom feeding to avoid without bottom and bottom shortage,decrease the rejection rate.

Description

LQ-ZSZB-D80S Automatic Middle Speed Paper Bowl Forming Machine is the automatic environmental machine with multi-running positions. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. If you need double pe coated paper cups or paper gram higher 250kg, we recommend you to use Ultrasonic set, it can produce single pe coated paper cups and double pe coated paper cups.

Main Feature

1. Use the vertical shaft system,open cam and gear driving system,automatic oil lubrication.

2. Forming section use separated cup bottom folding pre-heating section and knurling&curling section, reduce the machine loading and improve the balance of the whole section.

3. Use the individual cam to control the curling, knurling and pre-heating working position, more accurate and easy to operate.

4. Use the Pneumatic regulating valve to the adjust bottom paper feeding instead of the bottom feeding plate, install the sensor to check bottom feeding to avoid without bottom and bottom shortage,decrease the rejection rate.

Type: | LQ-ZSZB-D80S |

Cup size: | 2.5-16oz(Different size mold exchanged) |

Suitable paper material: | 150-380g/m2(single or double PE-coated paper) |

Capacity: | 70-90pcs/min |

Power source:: | 380V 50HZ(please inform us your power in advanced) |

Working power: | 5KW |

Weight: | 2600KG |

Total Power: | 8KW |

Package size: | 2200 x 1300 x 1800 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A:Top diameter: Min 50mm---Max 95mm B:Bottom diameter Min 30mm---Max 65mm C:Total height Min 33mm---Max135mm D:Bottom knurling depth Min 4mm---Max 10mm E: Rim diameter Usually Φ2.5---Φ3 |

Type: | LQ-ZSZB-D80S |

Cup size: | 2.5-16oz(Different size mold exchanged) |

Suitable paper material: | 150-380g/m2(single or double PE-coated paper) |

Capacity: | 70-90pcs/min |

Power source:: | 380V 50HZ(please inform us your power in advanced) |

Working power: | 5KW |

Weight: | 2600KG |

Total Power: | 8KW |

Package size: | 2200 x 1300 x 1800 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

| A:Top diameter: Min 50mm---Max 95mm B:Bottom diameter Min 30mm---Max 65mm C:Total height Min 33mm---Max135mm D:Bottom knurling depth Min 4mm---Max 10mm E: Rim diameter Usually Φ2.5---Φ3 |