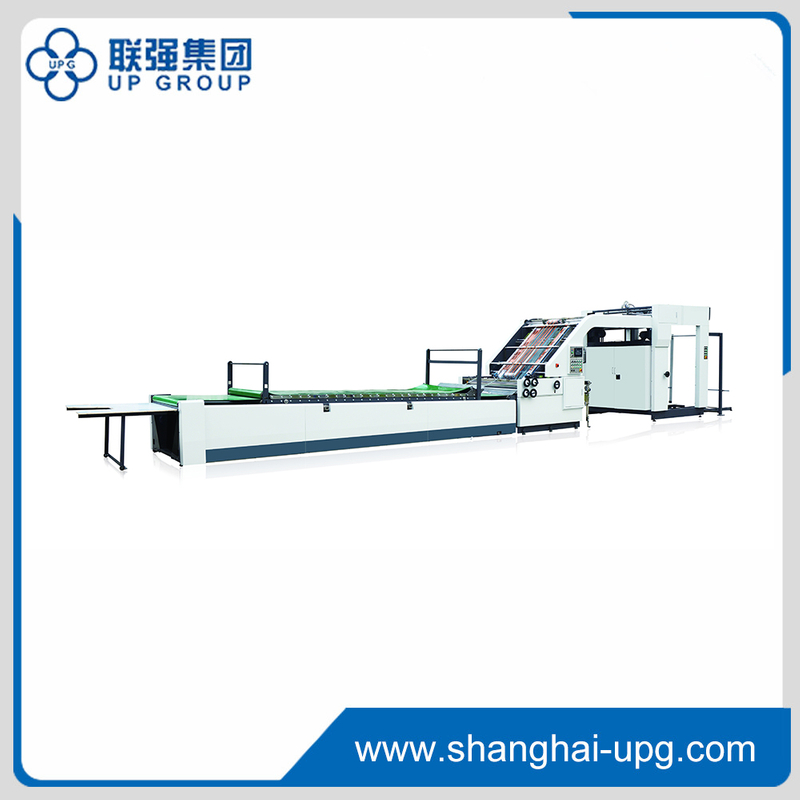

LQ-CY

UPG

Q:What’s its precision?

A:It’s ±1.5mm.

Q:How can the LQ-CY Automatic high speed paper mounting machine ensure its accuracy

A:The whole machine is driven by synchronous belt, with smooth transmission and low noise.At the same time, all wallboards are processed by large-scale machining center at one time to ensure the machining accuracy of each machining position.

Q:What are the advantages of this machine?

A:All the wallboards of this machine are made of large size and center in one process to ensure the processing accuracy of each processing position.The whole machine adopts synchronous belt transmission,the transmission is stable and the noise is small.The selected motor and its accessories are domestic and foreign famous brand products,higher efficiency,low failure rate,long service life.

●Computerized high speed lamination up to 180m/min, which depends on sheets.

●E shape lifting board used for the feeding unit enables sheets to be pushed into position by hydraulic jack. Rail with pre-piling device are available for option.

●Self-made four sucking and four forwarding suckers for the feeder ensures smooth running with no missing of sheet even at high speed.

●Sensing and compensation and alignment device uses several group of sensors to sense the relative position of the running corrugated board so that two servo motors at left and right side of the top paper can drive independently to align top paper with corrugated paper with high accuracy and high speed.

●Global-functional electric control system with touch screen and PLC program monitors automatically the working condition and facilitate trouble shooting. The electric design conforms to the CE standard.

●Gluing unit uses high precise coating wheels, together with specially designed metering steel roller enhances the evenness of gluing. The unique gluing wheel with glue stopping device and automatic glue level control system guarantees backflow with no overflow of glue.

●Machine frames are processed by CNC lathe in one process, which ensures the precise of every positions. Toothed belts for transferring guarantees smooth running with low noise. Motors and the spares uses Chinese famous brand with high efficiency, less trouble and long service life.

●Corrugated board feeding unit adopts powerful servo motor control system with the features of high sensitivity and fast speed. The suction unit uses high-pressure blower,SMC high- flow control valve as well as unique dust collection filter box, which enhances suction force for different corrugated paper, ensuring smooth running with no double or more sheets, no missing sheet.

Q:What’s its precision?

A:It’s ±1.5mm.

Q:How can the LQ-CY Automatic high speed paper mounting machine ensure its accuracy

A:The whole machine is driven by synchronous belt, with smooth transmission and low noise.At the same time, all wallboards are processed by large-scale machining center at one time to ensure the machining accuracy of each machining position.

Q:What are the advantages of this machine?

A:All the wallboards of this machine are made of large size and center in one process to ensure the processing accuracy of each processing position.The whole machine adopts synchronous belt transmission,the transmission is stable and the noise is small.The selected motor and its accessories are domestic and foreign famous brand products,higher efficiency,low failure rate,long service life.

●Computerized high speed lamination up to 180m/min, which depends on sheets.

●E shape lifting board used for the feeding unit enables sheets to be pushed into position by hydraulic jack. Rail with pre-piling device are available for option.

●Self-made four sucking and four forwarding suckers for the feeder ensures smooth running with no missing of sheet even at high speed.

●Sensing and compensation and alignment device uses several group of sensors to sense the relative position of the running corrugated board so that two servo motors at left and right side of the top paper can drive independently to align top paper with corrugated paper with high accuracy and high speed.

●Global-functional electric control system with touch screen and PLC program monitors automatically the working condition and facilitate trouble shooting. The electric design conforms to the CE standard.

●Gluing unit uses high precise coating wheels, together with specially designed metering steel roller enhances the evenness of gluing. The unique gluing wheel with glue stopping device and automatic glue level control system guarantees backflow with no overflow of glue.

●Machine frames are processed by CNC lathe in one process, which ensures the precise of every positions. Toothed belts for transferring guarantees smooth running with low noise. Motors and the spares uses Chinese famous brand with high efficiency, less trouble and long service life.

●Corrugated board feeding unit adopts powerful servo motor control system with the features of high sensitivity and fast speed. The suction unit uses high-pressure blower,SMC high- flow control valve as well as unique dust collection filter box, which enhances suction force for different corrugated paper, ensuring smooth running with no double or more sheets, no missing sheet.

| Model | LQ- CY 13145 | LQ - CY 14145 | LQ - CY 16165 |

| Max. sheet size | 1300×1450mm | 1400&×1450mm | 1600×1650mm |

| Min. sheet size | 450×450mm | 450×450mm | 450×;450mm |

| Max. sheet weight | 550g/㎡ | 550g/㎡ | 550g/m㎡ |

| Min. sheet weight | 157g/㎡ | 157g/㎡ | 157g/m² |

| Max. sheet thickness | 10mm | 10mm | 10mm |

| Min. sheet thickness | 0.5mm | 0.5mm | 0.5mm |

| Max. laminating speed | 180m/min | 180m/min | 180m/min |

| Lamination error | ±1.5mm | ±1.5mm | ±1.5mmmm |

| Total power | 22KW | 22KW | 22KW |

| Overall dimensions(L×W×H) | 15000×2100×2350mm | 15000×2250×2350mm | 15600×2450×2350mm |

| Total weight | 7200kg | 7500kg | 8500kg |

| Model | LQ- CY 13145 | LQ - CY 14145 | LQ - CY 16165 |

| Max. sheet size | 1300×1450mm | 1400&×1450mm | 1600×1650mm |

| Min. sheet size | 450×450mm | 450×450mm | 450×;450mm |

| Max. sheet weight | 550g/㎡ | 550g/㎡ | 550g/m㎡ |

| Min. sheet weight | 157g/㎡ | 157g/㎡ | 157g/m² |

| Max. sheet thickness | 10mm | 10mm | 10mm |

| Min. sheet thickness | 0.5mm | 0.5mm | 0.5mm |

| Max. laminating speed | 180m/min | 180m/min | 180m/min |

| Lamination error | ±1.5mm | ±1.5mm | ±1.5mmmm |

| Total power | 22KW | 22KW | 22KW |

| Overall dimensions(L×W×H) | 15000×2100×2350mm | 15000×2250×2350mm | 15600×2450×2350mm |

| Total weight | 7200kg | 7500kg | 8500kg |