| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

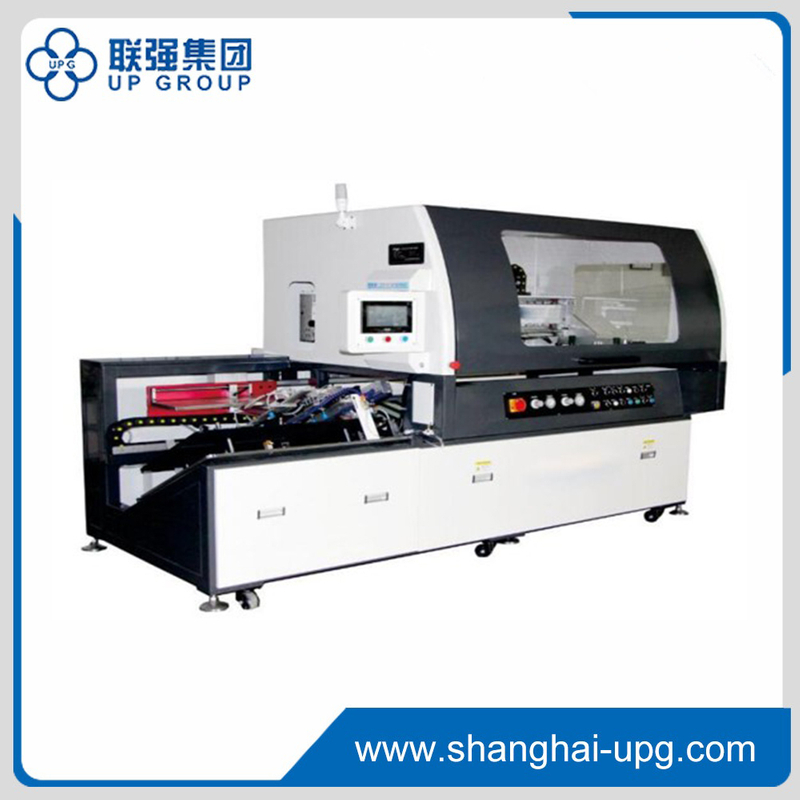

LQ-SY

UPG

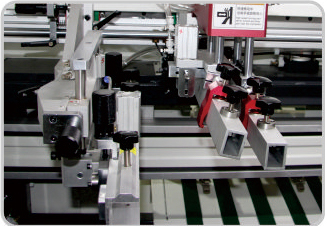

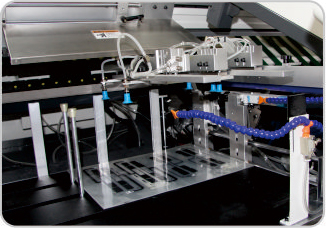

1. Automatic printing part: including automatic feeding, automatic dust removal, automatic printing, and automatic unloading devices.

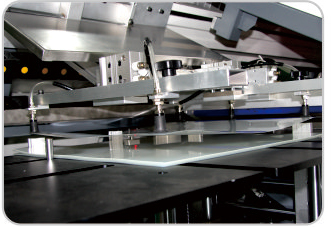

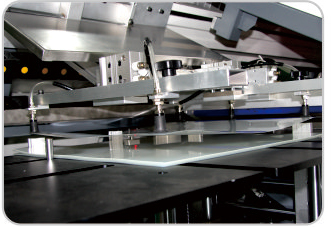

2. The printing platform is made of imported hard aluminum materials to ensure that the platform remains flat for a long time.

3. Printing area: 500*700MM

4. Printing speed: 600~800 times/hour adjustable

5. Servo motor drives printing to achieve high-quality printing

6. Japan servo printing motor

7. Touch screen operation control, the program has three modes of manual, semi-automatic and automatic.

8. The printing head lifts the board, and the angle of the scraper/returning knife can be adjusted arbitrarily.

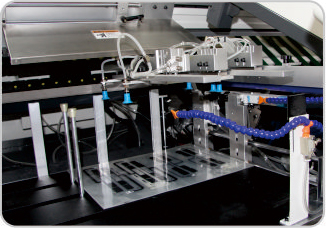

9. The size of the left and right screens can be adjusted arbitrarily, equipped with pneumatic cylinders to lock the screens and safety devices to structure

10. The thickness of the substrate is 0.075-1MM, which can be adjusted arbitrarily.

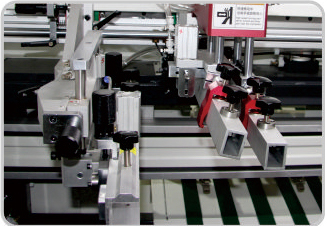

11. Fully automatic feeding: manually place the material frame on the feeding, and the equipment can complete each process by itself.

LED-UV Curing System High-speed Servo Optical Fiber Automatic

Feeding Manipulator Identification system

1. Automatic printing part: including automatic feeding, automatic dust removal, automatic printing, and automatic unloading devices.

2. The printing platform is made of imported hard aluminum materials to ensure that the platform remains flat for a long time.

3. Printing area: 500*700MM

4. Printing speed: 600~800 times/hour adjustable

5. Servo motor drives printing to achieve high-quality printing

6. Japan servo printing motor

7. Touch screen operation control, the program has three modes of manual, semi-automatic and automatic.

8. The printing head lifts the board, and the angle of the scraper/returning knife can be adjusted arbitrarily.

9. The size of the left and right screens can be adjusted arbitrarily, equipped with pneumatic cylinders to lock the screens and safety devices to structure

10. The thickness of the substrate is 0.075-1MM, which can be adjusted arbitrarily.

11. Fully automatic feeding: manually place the material frame on the feeding, and the equipment can complete each process by itself.

LED-UV Curing System High-speed Servo Optical Fiber Automatic

Feeding Manipulator Identification system

Model | LQ - SY 4570 | LQ - SY 5075 |

Dimension | 2400×1300×1850mm(L×W×H) | 2600×1300×1850mm(L×W×H) |

Weight | About 500 KG | About 550 KG |

Height of work surface from ground | 850±30mm | 850±30mm |

Printing Size | 600*800mm | 600*850mm |

Max Printing Size | 450*700mm | 500*750mm |

Max Screen frame size | 800*1100mm | 800*1200mm |

Frame thickness range | 20-30mm | 20-30mm |

Printing thickness | 0.1-4mm | 0.1-4mm |

Power supply | single phase、220v、50hz | single phase、220v、50hz |

Air pressure | 5-6Kgf/cm2PSI | 5-6Kgf/cm2PSI |

Power | 3.5KW | 3.5KW |

Air consumption | 1.48L/cycle | 1.48L/cycle |

Model | LQ - SY 4570 | LQ - SY 5075 |

Dimension | 2400×1300×1850mm(L×W×H) | 2600×1300×1850mm(L×W×H) |

Weight | About 500 KG | About 550 KG |

Height of work surface from ground | 850±30mm | 850±30mm |

Printing Size | 600*800mm | 600*850mm |

Max Printing Size | 450*700mm | 500*750mm |

Max Screen frame size | 800*1100mm | 800*1200mm |

Frame thickness range | 20-30mm | 20-30mm |

Printing thickness | 0.1-4mm | 0.1-4mm |

Power supply | single phase、220v、50hz | single phase、220v、50hz |

Air pressure | 5-6Kgf/cm2PSI | 5-6Kgf/cm2PSI |

Power | 3.5KW | 3.5KW |

Air consumption | 1.48L/cycle | 1.48L/cycle |