- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

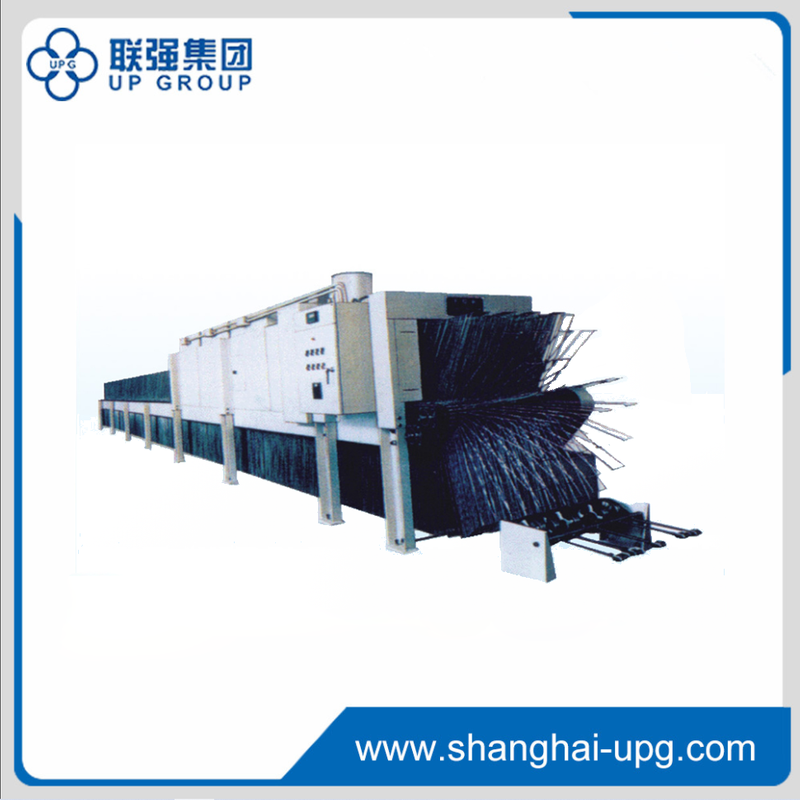

LQSH-720/780/1020

UPG

LQSH-720/780/1020 Single-lane Industrial Wicket Dryer designed with drying technology, is widely used for the drying area in the printing industries of ceramic decal, glass decal, packing printing, and credit printing etc. It can be equipped with the closed dust system. It can not only run stand-alone to dry the printing sheets, but also be in line with printing machines. It Features:

1.It is equipped with three hot air sections, and fan cooling system. It can be equipped with different drying sections according to job requests.

2.Page-down vertical movement, wicket feeding with paper, electric heating jet and natural drying.

3.When working in line, it is driven synchronization with the main printing machine. When the main machine stops, it can be driven slowly by itself.

4.As an option, when it is driven by gap-type transmission, via the photoelectric control paper wicket gap, driving the conveyor belt and adjusting the speed of paper feeding.

LQSH-720/780/1020 Single-lane Industrial Wicket Dryer designed with drying technology, is widely used for the drying area in the printing industries of ceramic decal, glass decal, packing printing, and credit printing etc. It can be equipped with the closed dust system. It can not only run stand-alone to dry the printing sheets, but also be in line with printing machines. It Features:

1.It is equipped with three hot air sections, and fan cooling system. It can be equipped with different drying sections according to job requests.

2.Page-down vertical movement, wicket feeding with paper, electric heating jet and natural drying.

3.When working in line, it is driven synchronization with the main printing machine. When the main machine stops, it can be driven slowly by itself.

4.As an option, when it is driven by gap-type transmission, via the photoelectric control paper wicket gap, driving the conveyor belt and adjusting the speed of paper feeding.

| Model | LQSH-720 | LQSH-780 | LQSH-1020 |

| Max. Conveying Width (mm) | 750x520 | 780x540 | 1020x740 |

| Stand-alone Speed (p/h) | 2000 | 2000 | 2000 |

| In-line Speed (p/h) | synchronization with main machine | synchronization with main machine | synchronization with main machine |

| Number Of Clamps (pcs) | 1348 | 1348 | 1078 |

| Max. Heating Temperature (℃) | 50 | 50 | 50 |

| Electric Heating Power (kw) | 19.2 | 19.2 | 28.8 |

| Total Power (kw) | 22 | 22 | 31 |

| Machine Weight (kg) | 6000 | 6000 | 6000 |

| Dimension (LxWxH) (mm) | 18500x1700x2200 | 18500x1800x2200 | 18500x2000x2400 |

| Model | LQSH-720 | LQSH-780 | LQSH-1020 |

| Max. Conveying Width (mm) | 750x520 | 780x540 | 1020x740 |

| Stand-alone Speed (p/h) | 2000 | 2000 | 2000 |

| In-line Speed (p/h) | synchronization with main machine | synchronization with main machine | synchronization with main machine |

| Number Of Clamps (pcs) | 1348 | 1348 | 1078 |

| Max. Heating Temperature (℃) | 50 | 50 | 50 |

| Electric Heating Power (kw) | 19.2 | 19.2 | 28.8 |

| Total Power (kw) | 22 | 22 | 31 |

| Machine Weight (kg) | 6000 | 6000 | 6000 |

| Dimension (LxWxH) (mm) | 18500x1700x2200 | 18500x1800x2200 | 18500x2000x2400 |