| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-JTCQ-D900/1200

UPG

Machine Advantages:

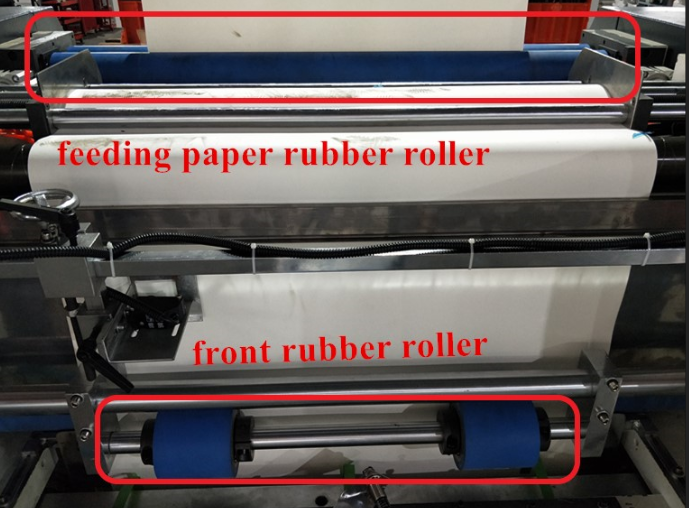

1.The center gravity of rubber roller move forward to stabilize the machine structure, and shorten the distance of feeding paper. That minimizes jitter; makes sure paper feeding stable and fast.

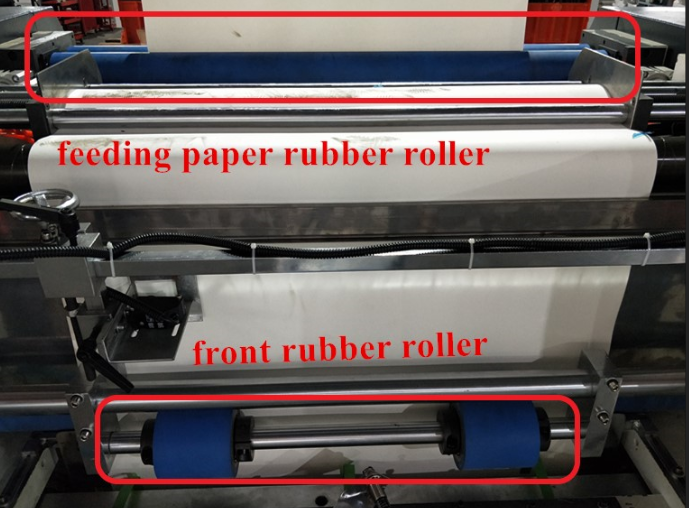

2.The front rubber roller adjusts the balance of paper in horizontal direction.

3. Machine adopt IOT technology. Not only Customer can supervise the machine operation situation on Mobile APP, manufacturer also can through this app to fullful remote control to provide the after-sale service. So both of two parts can save the service time and money.

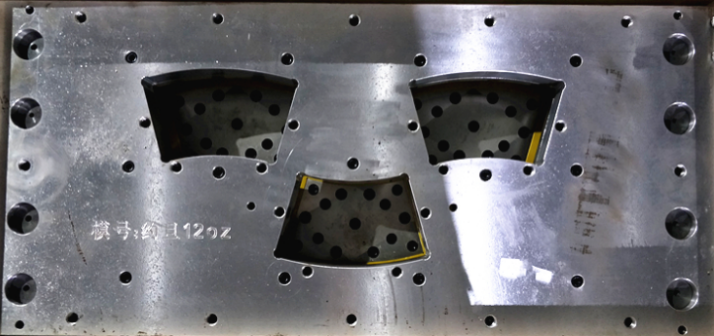

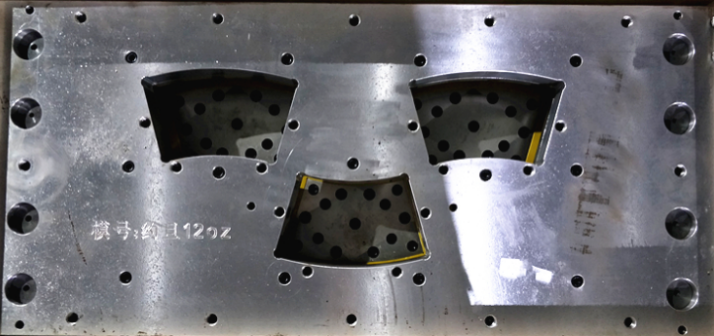

4. Instead of two links, new type die punching machine adopts four links. The metal die connected by four joints, the support force enhanced. It prolongs machine life, improves the stability; and significantly reduces the noise when machine is running.

5.Automatic oil injection system. It can be set by two hours one time, to reduce the machine abrasion, prolong machine life.

Machine Advantages:

1.The center gravity of rubber roller move forward to stabilize the machine structure, and shorten the distance of feeding paper. That minimizes jitter; makes sure paper feeding stable and fast.

2.The front rubber roller adjusts the balance of paper in horizontal direction.

3. Machine adopt IOT technology. Not only Customer can supervise the machine operation situation on Mobile APP, manufacturer also can through this app to fullful remote control to provide the after-sale service. So both of two parts can save the service time and money.

4. Instead of two links, new type die punching machine adopts four links. The metal die connected by four joints, the support force enhanced. It prolongs machine life, improves the stability; and significantly reduces the noise when machine is running.

5.Automatic oil injection system. It can be set by two hours one time, to reduce the machine abrasion, prolong machine life.

Technical Specification | ||

Type | LQ-JTCQ-D900 | LQ-JTCQ-D1200 |

Production capacity | 300-400 times/min(Mechanical speed max400 times) | |

Max Paper Convey Width | 870-300mm | 1170-300mm |

Maximum cutting size | 850*350mm | 1150*350mm |

Total Weight: | 3580KGS | 5100KGS |

Overall Dimension: | 3450 x 2100 x 1850 mm | 3450 x 2300 x 1850 mm |

Total Power: | 9KW | 10KW |

Suitable Material: | 1120-450g/m2 PE coated paper, white cardboard paper | |

Total Power and Air source: | 0.4Mpa; 0.3m³/min; 380V/50HZ (other voltage can be customized) | |

Max Roll paper diameter | 1500mm | |

Cut Precision: | ± 0.20mm | |

Mold weight&Size | 900type: 400kg 1050*500*260(mm) 1200type: 500kg 1420*500*240(mm) package size:H370 w560 L1140 | |

Machine can be customized by different customer’s demand | ||

Technical Specification | ||

Type | LQ-JTCQ-D900 | LQ-JTCQ-D1200 |

Production capacity | 300-400 times/min(Mechanical speed max400 times) | |

Max Paper Convey Width | 870-300mm | 1170-300mm |

Maximum cutting size | 850*350mm | 1150*350mm |

Total Weight: | 3580KGS | 5100KGS |

Overall Dimension: | 3450 x 2100 x 1850 mm | 3450 x 2300 x 1850 mm |

Total Power: | 9KW | 10KW |

Suitable Material: | 1120-450g/m2 PE coated paper, white cardboard paper | |

Total Power and Air source: | 0.4Mpa; 0.3m³/min; 380V/50HZ (other voltage can be customized) | |

Max Roll paper diameter | 1500mm | |

Cut Precision: | ± 0.20mm | |

Mold weight&Size | 900type: 400kg 1050*500*260(mm) 1200type: 500kg 1420*500*240(mm) package size:H370 w560 L1140 | |

Machine can be customized by different customer’s demand | ||

(Option)-1: ( Airshaftless system)

1. It bears much more weight than standard airshaft.

2. It fits any roll paper core sizes.

(option)-2:(metal die made in different material)

(option)-3:Wastage Paper output by side way

waste paper is delivered by side way. we don't need move the waste paper by man hand.

which can save one worker's cost.

(Option)-1: ( Airshaftless system)

1. It bears much more weight than standard airshaft.

2. It fits any roll paper core sizes.

(option)-2:(metal die made in different material)

(option)-3:Wastage Paper output by side way

waste paper is delivered by side way. we don't need move the waste paper by man hand.

which can save one worker's cost.