| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD PCM

UPG

Control system

Equipped with the advanced multi-axis high-speed motion control system with independent intellectual property rights, the system upgrade and maintenance are not controlled by the third party, the late maintenance is convenient, high reliability, low cost, because the right of control is in hand, it can be convenient for users to customize special procedures for personalized needs and remote upgrade;

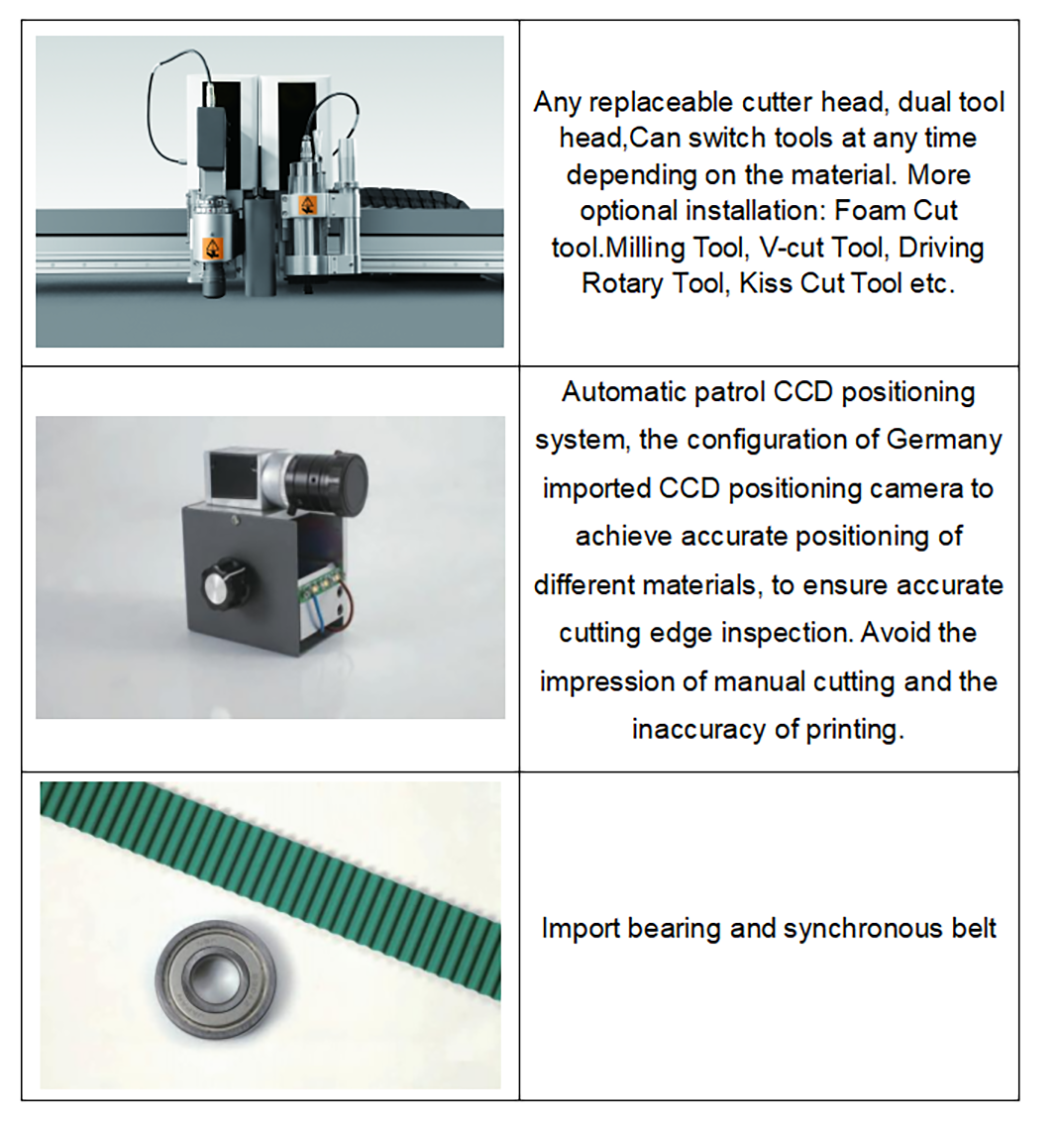

Head design

The use of changeable tool head mode, tool head is not fixed welding integration, can be based on the actual work needs and business scope expansion of convenient replacement, with different functions of the tool head;

Safety protection

The beam working area is equipped with 360 degrees of safety anti-collision and infrared blocking technology to ensure the safety of users.

Features

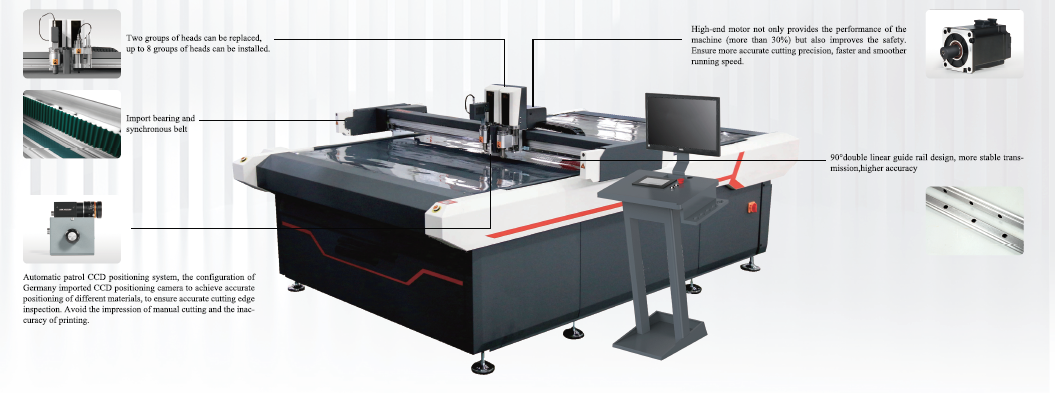

Import bearing and synchronous belt

High-end motor not only provides the performance of the machine (more than 30%) but also improves the safety. Ensure more accurate cutting precision, faster and smoother running speed.

Two groups of heads can be replaced,up to 8 groups of heads can be installed.

90°double linear guide rail design,more stable transmission,higher accuracy

Control system

Equipped with the advanced multi-axis high-speed motion control system with independent intellectual property rights, the system upgrade and maintenance are not controlled by the third party, the late maintenance is convenient, high reliability, low cost, because the right of control is in hand, it can be convenient for users to customize special procedures for personalized needs and remote upgrade;

Head design

The use of changeable tool head mode, tool head is not fixed welding integration, can be based on the actual work needs and business scope expansion of convenient replacement, with different functions of the tool head;

Safety protection

The beam working area is equipped with 360 degrees of safety anti-collision and infrared blocking technology to ensure the safety of users.

Features

Import bearing and synchronous belt

High-end motor not only provides the performance of the machine (more than 30%) but also improves the safety. Ensure more accurate cutting precision, faster and smoother running speed.

Two groups of heads can be replaced,up to 8 groups of heads can be installed.

90°double linear guide rail design,more stable transmission,higher accuracy

Model | PCM-1310 | PCM-1815 | PCM-2516 |

Effective working range | 1300*1000mm | 1800*1500mm | 2500*1600mm |

Overall size | 2700*1985*1350mm | 3200*2485*1350mm | 3900*2585*1350mm |

Air pump power | 5.5KW | 7.5KW | 7.5KW |

Cutting materials | All kinds of corrugated cardboard,plastic corrugated board,yellow thick cardboard,red cardboard,white cardboard,gray cardboard,PVC board,foam board,EVA board,KT board,stickers,gaskets,etc. | ||

Working Characteristics | Can be connected to any CAD software,computer-aided design and cutting at the same time | ||

Standard tools | Oscillating tool,Creasing wheel,Pen,Double cross cursor,Gray card V-cut tool,Universal cutting tool | ||

Optional tools | V-CUT tool,white card V-cut tool,Foam cut tool,CCD camera | ||

Cutting thickness | 50MM (according to different cutting materials) | ||

Speed | 1000mm/s | ||

Fixing method | Vacuum adsorption | ||

Repeat accuracy | ≤0.01mm | ||

Software resolution | 0.025、0.01、0.1 | ||

Transmission port | Standard network port | ||

Buffer capacity | 1G,one-time fast transfer of page changeable cuts | ||

User interface | 7-inch color touch screen | ||

Drive line | High-end digital servo motor drive,linear guide | ||

Operating Voltage/Power | AC380V±10%,50HZ | ||

Model | PCM-1310 | PCM-1815 | PCM-2516 |

Effective working range | 1300*1000mm | 1800*1500mm | 2500*1600mm |

Overall size | 2700*1985*1350mm | 3200*2485*1350mm | 3900*2585*1350mm |

Air pump power | 5.5KW | 7.5KW | 7.5KW |

Cutting materials | All kinds of corrugated cardboard,plastic corrugated board,yellow thick cardboard,red cardboard,white cardboard,gray cardboard,PVC board,foam board,EVA board,KT board,stickers,gaskets,etc. | ||

Working Characteristics | Can be connected to any CAD software,computer-aided design and cutting at the same time | ||

Standard tools | Oscillating tool,Creasing wheel,Pen,Double cross cursor,Gray card V-cut tool,Universal cutting tool | ||

Optional tools | V-CUT tool,white card V-cut tool,Foam cut tool,CCD camera | ||

Cutting thickness | 50MM (according to different cutting materials) | ||

Speed | 1000mm/s | ||

Fixing method | Vacuum adsorption | ||

Repeat accuracy | ≤0.01mm | ||

Software resolution | 0.025、0.01、0.1 | ||

Transmission port | Standard network port | ||

Buffer capacity | 1G,one-time fast transfer of page changeable cuts | ||

User interface | 7-inch color touch screen | ||

Drive line | High-end digital servo motor drive,linear guide | ||

Operating Voltage/Power | AC380V±10%,50HZ | ||