| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-TYM 800-H

UPG

TYM800-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. It’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliability, high speed, press and precision.

Features

● Longitudinal and lateral foil stamping devices are equipped which make foil stamping process more reasonable.

● The longitudinal foil-delivering unit can be pulled out when you install the foil, convenient for operation.

● Foil-stringing device by hand is used which improves the efficiency of work.

● The registration of foil stamping steel plate adopts side-press registering structure, which improves the accuracy of repeat registration.

● Pneumatic plate-locking device is equipped which improves the level of automation.

● The main driving chain adopts big-pitch chains, which reduces the inertia of running, improves stability of precision; Force moment controller is used which improves the coefficient of safety.

● The front-and-back registration of gripper bars adjustable device, convenient to adjust the precision of front lay.

● The front lay adopts numerical control from former adjustment by hand, convenient and audio-visual.

● Cooling device for lubricating oil is added which reduces the wear of parts when they are heated, ensures the constant pressure of diecutting and foil stamping.

● Cooling device for electrical box is added which improves the life of electrical parts.

Safety system

The machine with four degree safety class, equipped with protection modules has got CE certificate of high-speed and stable performance.

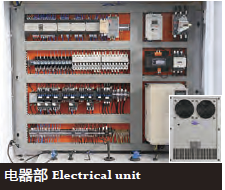

Electrical unit

* Imported electronic elements and panels with humanization control layout to ensure easy operation.

* Equipped constant Temperature Devices to ensure reliable working and prolong service life.

Feeding unit

The design of double column type pre-stack unit ensures convenient and efficient operation. Feeder with collision-prevention device. Adopt high-speed feeder with adjustable strong type suckers to guarantee stable and smooth paper feeding.

Movable Platform

Unique cast structure and specific working process ensure evenness and flatness and pressure-regulating time. Oil cooling system ensures constant pressure. Electrically pressure-regulating system ensures convenient and efficient regulating. Pressure-regulating can be achieved only by entering value.

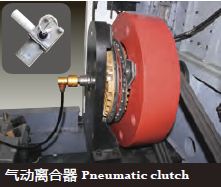

Pneumatic clutch

Imported components to lower noise and pneumatic impact for stable and safe running.

Front Lay

The front lay can be individually adjusted by four sites for different paper processing requirement. Unique electrically pressure-regulating device realizes plate regulating in delivery unit, ensuring convenient and efficient front lay regulating. Values visually displayed on man-machine interface.

Delivering unit

Add foot-pressing preventer for further safety. Unique deceleration hairbrush ensures paper stopping stably. Tension device for drive chain of gripper bar prolongs the gripper bar's service life. Pneumatic sampling device for convenient sampling at any time with the machine running.

Feeding unit

Drive chain adopted in feeding unit to ensure stable run and reliable paper feeding. Gas spring for easy and convenient operation. Adjustable reduction unit for paper to front lay, helps to thinner paper positioning at high speed. Side lay with dual purpose for side positioning can be easily switched.

Foil stamping unit

Worm shaft, worm wheel and crankshaft with unique working process greatly improve the service life of core components. Pneumatic plate-locking for convenient operation. Single gripper bar can be fine adjusted to achieve processing requirement. The honeycomb plate also adopts high heatproof material through a specific working process with optimized hole-layout, convenient for the installation of foil-stamping block.

Foil-sending and rewinding system

Three longitudinal and two lateral foil two(stamping) shafts are equipped to meet the demand for different products. Its 8 heating zones can be controlled separately. The longitudinal foil-stringing unit can be pulled out when you install the foil, convenient for operation. Foil-step is controlled by motion controller adopting optimized accelerating and decelerating curves, for more steady and accurate foil-controlling.

Gripper bar chain

*Torsion controller equipped to make gripper bar run safely;

*The gripper bar of special structure and material to guarantee low moment of inertia and impact;

*Nine grippers structure to ensure stronger gripper force and working accuracy at high speed

*Adopt optimized motion trail and improved motion curve to ensure stable and accurate running of gripper bars.

*Imported chain to prolong service life.

TYM800-H automatic foil stamping and diecutting machine is mainly used for the diecutting, creasing, foil stamping, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries. It’s incorporated with fully automatic feeding, diecutting, stamping, delivering foil, delivering sheet, up-press, down-press, leap step, counting, heating, pre-heating, obstacle indicating, checking and measuring. It has the features of easy operating, reliability, high speed, press and precision.

Features

● Longitudinal and lateral foil stamping devices are equipped which make foil stamping process more reasonable.

● The longitudinal foil-delivering unit can be pulled out when you install the foil, convenient for operation.

● Foil-stringing device by hand is used which improves the efficiency of work.

● The registration of foil stamping steel plate adopts side-press registering structure, which improves the accuracy of repeat registration.

● Pneumatic plate-locking device is equipped which improves the level of automation.

● The main driving chain adopts big-pitch chains, which reduces the inertia of running, improves stability of precision; Force moment controller is used which improves the coefficient of safety.

● The front-and-back registration of gripper bars adjustable device, convenient to adjust the precision of front lay.

● The front lay adopts numerical control from former adjustment by hand, convenient and audio-visual.

● Cooling device for lubricating oil is added which reduces the wear of parts when they are heated, ensures the constant pressure of diecutting and foil stamping.

● Cooling device for electrical box is added which improves the life of electrical parts.

Safety system

The machine with four degree safety class, equipped with protection modules has got CE certificate of high-speed and stable performance.

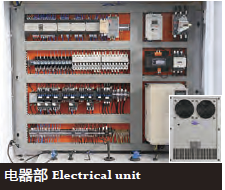

Electrical unit

* Imported electronic elements and panels with humanization control layout to ensure easy operation.

* Equipped constant Temperature Devices to ensure reliable working and prolong service life.

Feeding unit

The design of double column type pre-stack unit ensures convenient and efficient operation. Feeder with collision-prevention device. Adopt high-speed feeder with adjustable strong type suckers to guarantee stable and smooth paper feeding.

Movable Platform

Unique cast structure and specific working process ensure evenness and flatness and pressure-regulating time. Oil cooling system ensures constant pressure. Electrically pressure-regulating system ensures convenient and efficient regulating. Pressure-regulating can be achieved only by entering value.

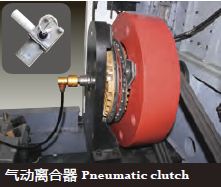

Pneumatic clutch

Imported components to lower noise and pneumatic impact for stable and safe running.

Front Lay

The front lay can be individually adjusted by four sites for different paper processing requirement. Unique electrically pressure-regulating device realizes plate regulating in delivery unit, ensuring convenient and efficient front lay regulating. Values visually displayed on man-machine interface.

Delivering unit

Add foot-pressing preventer for further safety. Unique deceleration hairbrush ensures paper stopping stably. Tension device for drive chain of gripper bar prolongs the gripper bar's service life. Pneumatic sampling device for convenient sampling at any time with the machine running.

Feeding unit

Drive chain adopted in feeding unit to ensure stable run and reliable paper feeding. Gas spring for easy and convenient operation. Adjustable reduction unit for paper to front lay, helps to thinner paper positioning at high speed. Side lay with dual purpose for side positioning can be easily switched.

Foil stamping unit

Worm shaft, worm wheel and crankshaft with unique working process greatly improve the service life of core components. Pneumatic plate-locking for convenient operation. Single gripper bar can be fine adjusted to achieve processing requirement. The honeycomb plate also adopts high heatproof material through a specific working process with optimized hole-layout, convenient for the installation of foil-stamping block.

Foil-sending and rewinding system

Three longitudinal and two lateral foil two(stamping) shafts are equipped to meet the demand for different products. Its 8 heating zones can be controlled separately. The longitudinal foil-stringing unit can be pulled out when you install the foil, convenient for operation. Foil-step is controlled by motion controller adopting optimized accelerating and decelerating curves, for more steady and accurate foil-controlling.

Gripper bar chain

*Torsion controller equipped to make gripper bar run safely;

*The gripper bar of special structure and material to guarantee low moment of inertia and impact;

*Nine grippers structure to ensure stronger gripper force and working accuracy at high speed

*Adopt optimized motion trail and improved motion curve to ensure stable and accurate running of gripper bars.

*Imported chain to prolong service life.

| Max. Paper Size | 800×620mm |

| Min. Paper Size | 360×290mm |

| Max. Diecutting Size | 790×610mm |

| Max. Foil Stamping Size | Longitudinal: 780×600mm Lateral: 800×500mm |

| Max. Diecutting Speed | 8000s/h |

| Max. Stamping Speed | 6000s/h |

| Max. Pressure | 200 T |

| Max. Foil Diameter | Ф195mm/3″ Ф100mm/1″ |

| Sheet Thickness | Cardboard:0.1-1.5mm Corrugated paper:≤4mm |

| Net Weight | 10.5 T |

| Total Power | 40.5kw |

| Quantities Of Heating Area | 8 |

| Overall Dimension | 5500×1450×1900mm |

| Max. Paper Size | 800×620mm |

| Min. Paper Size | 360×290mm |

| Max. Diecutting Size | 790×610mm |

| Max. Foil Stamping Size | Longitudinal: 780×600mm Lateral: 800×500mm |

| Max. Diecutting Speed | 8000s/h |

| Max. Stamping Speed | 6000s/h |

| Max. Pressure | 200 T |

| Max. Foil Diameter | Ф195mm/3″ Ф100mm/1″ |

| Sheet Thickness | Cardboard:0.1-1.5mm Corrugated paper:≤4mm |

| Net Weight | 10.5 T |

| Total Power | 40.5kw |

| Quantities Of Heating Area | 8 |

| Overall Dimension | 5500×1450×1900mm |