| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

ZH-QFP

UPG

Description

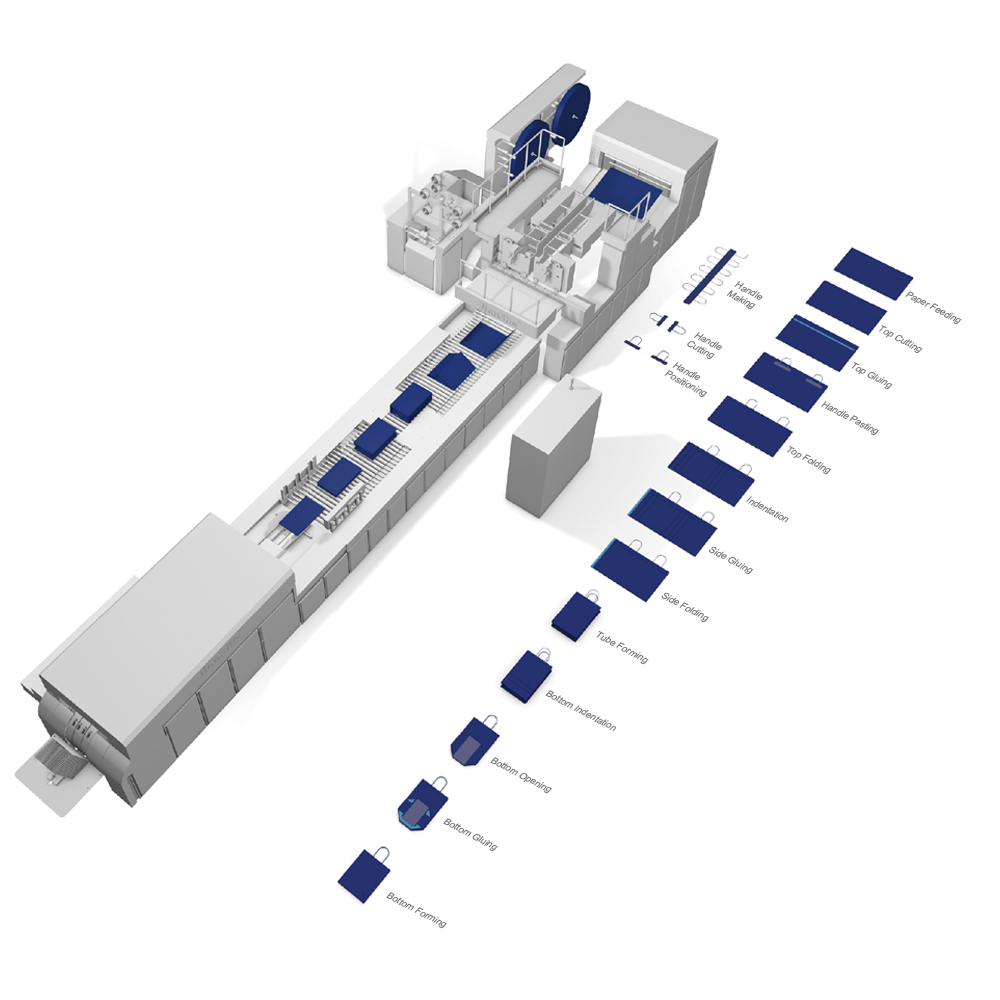

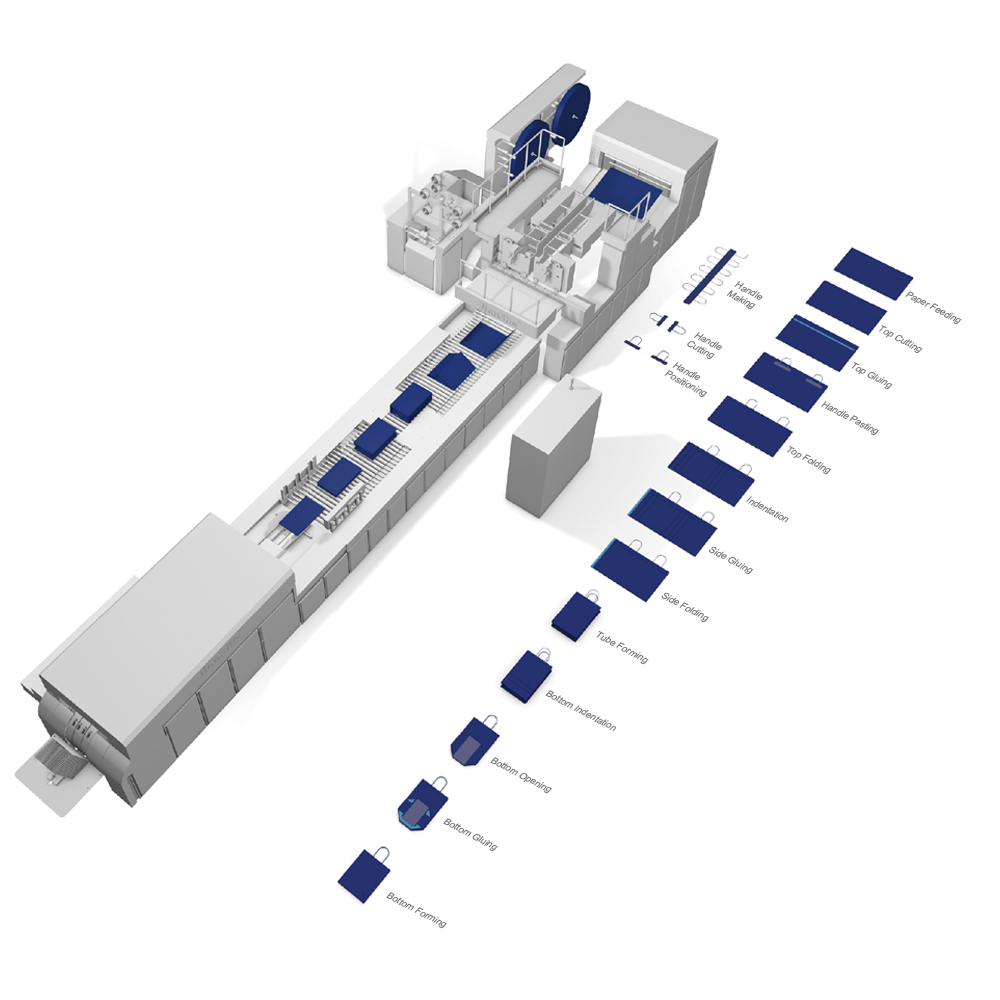

This machine is designed to manufacture small-sized square bottom paper bags with handles from sheet paper, paper patch roll and paper rope, and it is an ideal equipment for producing mid-to-high-end paper handbags, especially suitable for food, clothing and luxuries industries. By implementing steps including handle making, handle application, bag mouth folding, tube forming and bottom forming within a fully automatic process, this machine can effectively save labor costs. Equipped with advanced pre-heap paper feeder, this machine can realize non-stop feeding, thereby improving the production capacity.

Thanks to perfect technologies, the machine can produce paper handbags with high quality in many different forms, thoroughly liberate the hands for making small-sized paper handbags, and bring more profit for the customer.

This machine can make 3 diferent kinds of paper bags, according to customers' varlous requirements,from various kinds of paper, including kraft paper, coated paper and laminated paper, etc.

Optional scissor clamp system and toggle clamp system, bring machines the advantage of coping with thin paper as well as thick paper (toggle clamp system can process some kind of paper with thickness 250gsm).

Optional transfer systems (belt-type and roller-type) for tube forming, meet requirements of diferent paper bag making processes for various kinds of paper.

Special customized model design enlarges the production range of machines as well as the business range of customers(optional big/small side pasting device; bag width can reach 500mm or bottom size can reach 250mm).

Description

This machine is designed to manufacture small-sized square bottom paper bags with handles from sheet paper, paper patch roll and paper rope, and it is an ideal equipment for producing mid-to-high-end paper handbags, especially suitable for food, clothing and luxuries industries. By implementing steps including handle making, handle application, bag mouth folding, tube forming and bottom forming within a fully automatic process, this machine can effectively save labor costs. Equipped with advanced pre-heap paper feeder, this machine can realize non-stop feeding, thereby improving the production capacity.

Thanks to perfect technologies, the machine can produce paper handbags with high quality in many different forms, thoroughly liberate the hands for making small-sized paper handbags, and bring more profit for the customer.

This machine can make 3 diferent kinds of paper bags, according to customers' varlous requirements,from various kinds of paper, including kraft paper, coated paper and laminated paper, etc.

Optional scissor clamp system and toggle clamp system, bring machines the advantage of coping with thin paper as well as thick paper (toggle clamp system can process some kind of paper with thickness 250gsm).

Optional transfer systems (belt-type and roller-type) for tube forming, meet requirements of diferent paper bag making processes for various kinds of paper.

Special customized model design enlarges the production range of machines as well as the business range of customers(optional big/small side pasting device; bag width can reach 500mm or bottom size can reach 250mm).

| TECHNICAL DATA | ZH-QFP08 | ZH-QFP14 | ZH-QFP18 | ZH-QFP18S |

| Paper Width | 470~780mm | 550~1050mm | 630~1250mm | 710~1320mm |

| Paper Length | 310~530mm | 340~630mm | 340~630mm | 360-630mm |

| Paper Thickness | 100~160g/m2 | 100~220g/m2(250g/m2) | 100~220g/m2(250g/m2) | 100~220g/m2(250g/m2) |

| Bag Body Width | 135~250mm | 180~350mm | 220~450mm | 240~500mm |

| Bag Body Height | 215~395mm | 200~480mm | 200~480mm | 200~480mm |

| Bag Bottom Size | 60~130mm | 80~180mm | 80~180mm | 100-180mm |

| Bag Bottom Size | 35~55mm | 40~60mm | 40~60mm | 40~60mm |

| Handle Rope Height | 155~175mm | 170~185mm | 170~185mm | 170~185mm |

| Handle Rope Diameter | Ф4~6mm | Ф4~6mm | Ф4~6mm | Ф4~6mm |

| Handle Patch Length | 114.3mm | 152.4mm | 188.5mm | 188.5mm |

| Handle Patch Width | 40~50mm | 40~50mm | 40~50mm | 40-50mm |

| Paper Patch Roll Diameter | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm |

| Paper Patch Roll Width | 80~100mm | 80~100mm | 80~100mm | 80~100mm |

| Paper Patch Thickness | 100~250g/m2 | 100~250g/m2 | 100~250g/m2 | 100~250g/m2 |

| Max.Speed | 70bags/min | 70bags/min | 70bags/min | 70bags/min |

| Total Power | 22kw | 20kw | 22kw | 22kw |

| Total Weight | Approx.20000kg | Approx.22000kg | Approx.24000kg | Approx.25000kg |

| Overall Dimension | L13500xW4300xH2400mm | L16000xW4300xH2600mm | L16000xW4500×H2600mm | L16000xW4600×H2600mm |

| TECHNICAL DATA | ZH-QFP08 | ZH-QFP14 | ZH-QFP18 | ZH-QFP18S |

| Paper Width | 470~780mm | 550~1050mm | 630~1250mm | 710~1320mm |

| Paper Length | 310~530mm | 340~630mm | 340~630mm | 360-630mm |

| Paper Thickness | 100~160g/m2 | 100~220g/m2(250g/m2) | 100~220g/m2(250g/m2) | 100~220g/m2(250g/m2) |

| Bag Body Width | 135~250mm | 180~350mm | 220~450mm | 240~500mm |

| Bag Body Height | 215~395mm | 200~480mm | 200~480mm | 200~480mm |

| Bag Bottom Size | 60~130mm | 80~180mm | 80~180mm | 100-180mm |

| Bag Bottom Size | 35~55mm | 40~60mm | 40~60mm | 40~60mm |

| Handle Rope Height | 155~175mm | 170~185mm | 170~185mm | 170~185mm |

| Handle Rope Diameter | Ф4~6mm | Ф4~6mm | Ф4~6mm | Ф4~6mm |

| Handle Patch Length | 114.3mm | 152.4mm | 188.5mm | 188.5mm |

| Handle Patch Width | 40~50mm | 40~50mm | 40~50mm | 40-50mm |

| Paper Patch Roll Diameter | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm |

| Paper Patch Roll Width | 80~100mm | 80~100mm | 80~100mm | 80~100mm |

| Paper Patch Thickness | 100~250g/m2 | 100~250g/m2 | 100~250g/m2 | 100~250g/m2 |

| Max.Speed | 70bags/min | 70bags/min | 70bags/min | 70bags/min |

| Total Power | 22kw | 20kw | 22kw | 22kw |

| Total Weight | Approx.20000kg | Approx.22000kg | Approx.24000kg | Approx.25000kg |

| Overall Dimension | L13500xW4300xH2400mm | L16000xW4300xH2600mm | L16000xW4500×H2600mm | L16000xW4600×H2600mm |