| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

ZHJD-G350J

UPG

Description

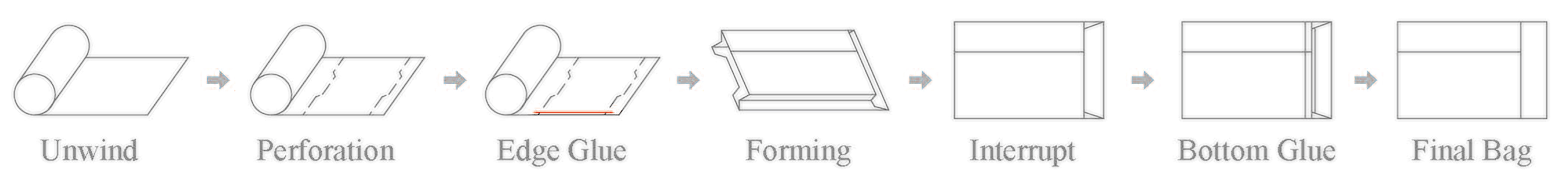

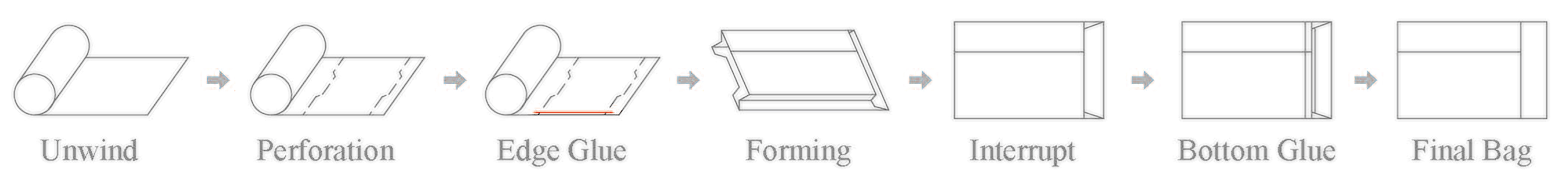

Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper,medico paper and so on, bag making process consist of puncture, side gluing, side folding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in one time. Our machine have advantage of easy operation, high efficiency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment-friendly paper bag.

Main Features

1.Germany LENZE Touch screen human-computer interface, operate and control easily.

2.Germany original LENZE control,integrated with optical fiber, ensure high speed running steadily.

3.Available Germany LENZE Servo Motor Integrated With Germany Original SICK Rectifying Photo.

4.Sensor, ensure the printed paper length under tracking precisely.

5.Raw Material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

6.Raw material unwinding EPC adopt Italy selectra, reduce adjustment time.

Description

Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper,medico paper and so on, bag making process consist of puncture, side gluing, side folding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in one time. Our machine have advantage of easy operation, high efficiency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment-friendly paper bag.

Main Features

1.Germany LENZE Touch screen human-computer interface, operate and control easily.

2.Germany original LENZE control,integrated with optical fiber, ensure high speed running steadily.

3.Available Germany LENZE Servo Motor Integrated With Germany Original SICK Rectifying Photo.

4.Sensor, ensure the printed paper length under tracking precisely.

5.Raw Material load adopt hydraulic pressure up and down structure, unwinding adopt auto tension control.

6.Raw material unwinding EPC adopt Italy selectra, reduce adjustment time.

| Model | ZHJD-G350J |

| Length Of Cutting Bag | 165-715mm |

| Bag Length (L) | 160-710mm |

| Bag width(w) | 70-350mm |

| Insert Size(G) | 20-120mm |

| Bag Mouth Height | 15/20mm |

| Production Speed | 50-650pcs/min |

| Paper Feed Width | 160-960mm |

| Paper Material Diameter | Ф1 100mm |

| Inner Diameter Of Paper | ф76mm |

| Paper Material Thiekness | 35-80g/m2 |

| Film width | 80-280mm |

| (OPP/PET)Rolling Fim Thickness | 0.020-0.037mm |

| Rolling Film Diameter | ф500mm |

| Working Air Current | More than 0.12m3/minutes,0.5-0.8MPa |

| Machine Power | 380V 3phase 4 line 32.1kw |

| Total Weight | 6500kg |

| Machine Dimesion | 6800*2900*2000mm |

| Model | ZHJD-G350J |

| Length Of Cutting Bag | 165-715mm |

| Bag Length (L) | 160-710mm |

| Bag width(w) | 70-350mm |

| Insert Size(G) | 20-120mm |

| Bag Mouth Height | 15/20mm |

| Production Speed | 50-650pcs/min |

| Paper Feed Width | 160-960mm |

| Paper Material Diameter | Ф1 100mm |

| Inner Diameter Of Paper | ф76mm |

| Paper Material Thiekness | 35-80g/m2 |

| Film width | 80-280mm |

| (OPP/PET)Rolling Fim Thickness | 0.020-0.037mm |

| Rolling Film Diameter | ф500mm |

| Working Air Current | More than 0.12m3/minutes,0.5-0.8MPa |

| Machine Power | 380V 3phase 4 line 32.1kw |

| Total Weight | 6500kg |

| Machine Dimesion | 6800*2900*2000mm |