| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-JD4740

LQ

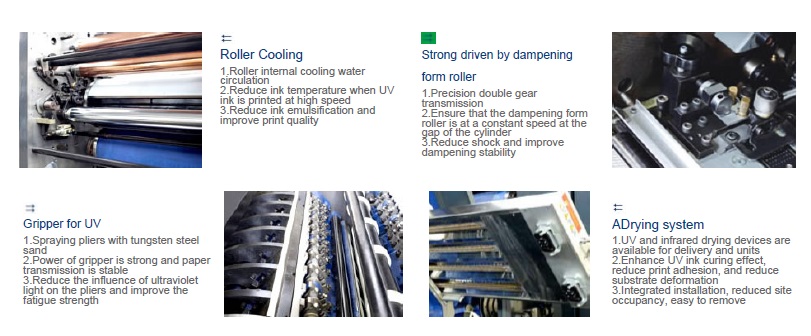

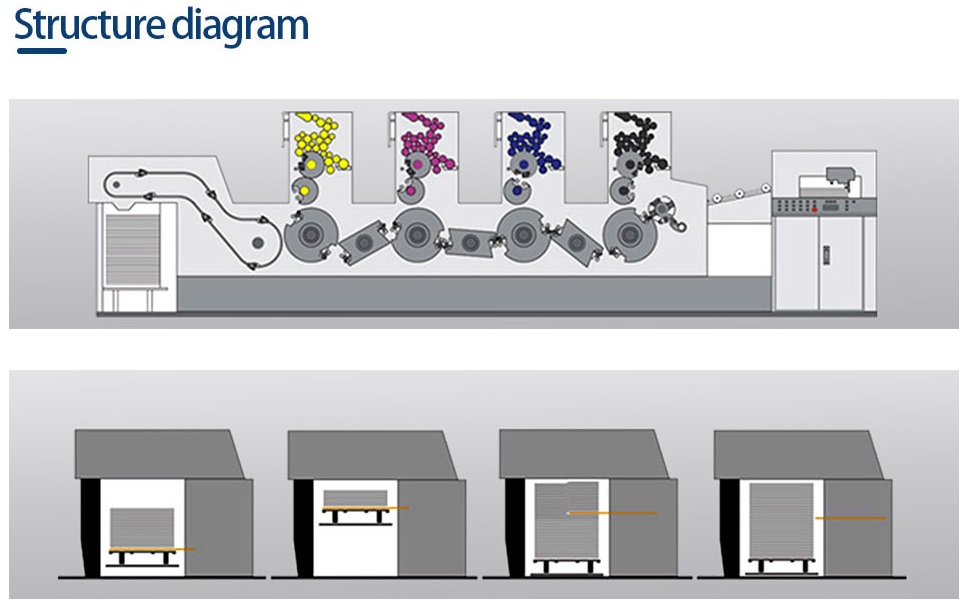

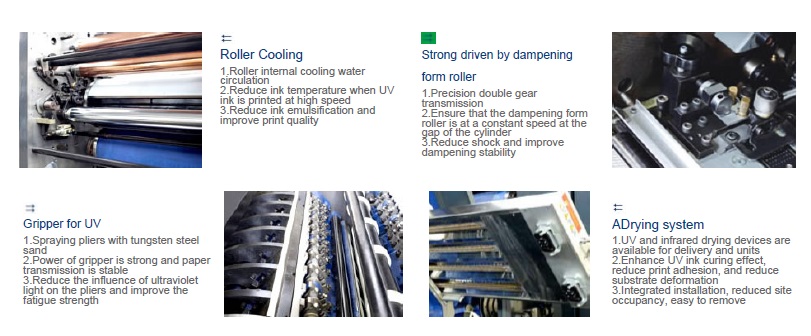

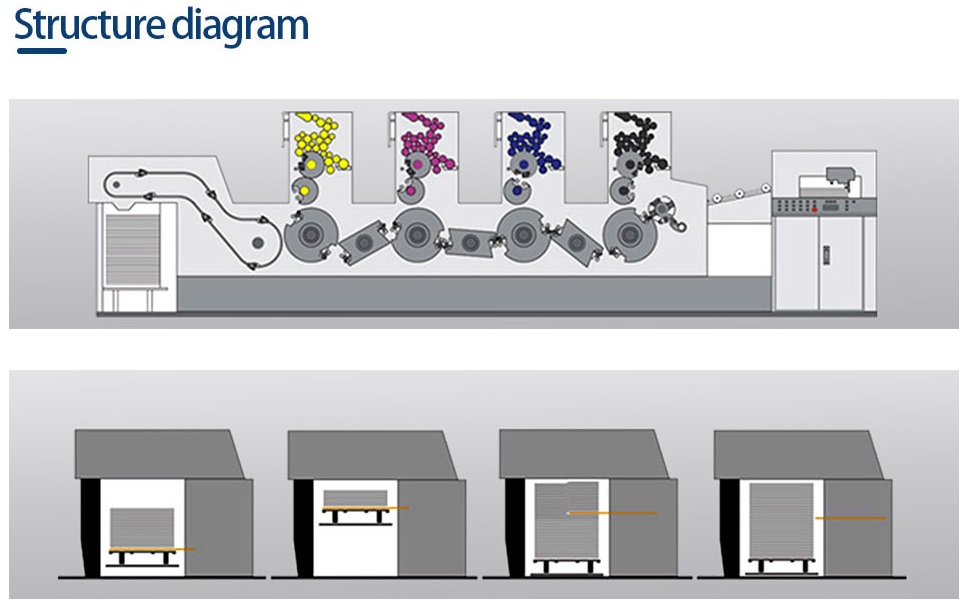

According to the development of the printing market, a new generation of multi-color offset printing machine built by a number of national patent technologies is adopted, which adopts automatic pneumatic clamping system, automatic three-axis adjustment system controlled by DC permanent magnet, and precise automatic pressure regulating system. With the bus electronic control system of Mitsubishi CC-LINK communication method, it perfectly displays the characteristics of smart, intelligent and high efficiency of the heavy-duty printing machine. The stainless steel spray embossing and plate cylinder greatly extend the life of the machine. CIP4 can be used to form a digital workflow with prepress CTP and postpress, and to preset the ink color, which greatly reduces the printing factories ' experience for printing technicians. Under certain conditions, the operating conditions and various parameter changes of the printing press can be monitored and controlled by INTERNET, and the popular UV printing, glazing and other printing processes as well as the automatic blanket washing and the ink roller can be conveniently installed. Increased scalability of product features.

According to the development of the printing market, a new generation of multi-color offset printing machine built by a number of national patent technologies is adopted, which adopts automatic pneumatic clamping system, automatic three-axis adjustment system controlled by DC permanent magnet, and precise automatic pressure regulating system. With the bus electronic control system of Mitsubishi CC-LINK communication method, it perfectly displays the characteristics of smart, intelligent and high efficiency of the heavy-duty printing machine. The stainless steel spray embossing and plate cylinder greatly extend the life of the machine. CIP4 can be used to form a digital workflow with prepress CTP and postpress, and to preset the ink color, which greatly reduces the printing factories ' experience for printing technicians. Under certain conditions, the operating conditions and various parameter changes of the printing press can be monitored and controlled by INTERNET, and the popular UV printing, glazing and other printing processes as well as the automatic blanket washing and the ink roller can be conveniently installed. Increased scalability of product features.

| Model | LQJD-4740 |

| Machine Speed | 12000s.p.h |

| Max. Sheet Size | 540 x 740mm |

| Min. Sheet Size | 273 x 393mm |

| Sheet Thickness | 0.06-0.6mm |

| Max. image area | 528 x 730mm |

| Plate Size | 677 x 755 x 0.3mm |

| Blanket Size | 740 x 760mm |

| Max. Feeder Pile height | 940mm |

| Max. Delivery Pile height | 780mm |

| Overall Dimensions | 7380 x 2880 x 1870mm |

| Total Power | 23kw |

| Weight | 19700kg |

| Model | LQJD-4740 |

| Machine Speed | 12000s.p.h |

| Max. Sheet Size | 540 x 740mm |

| Min. Sheet Size | 273 x 393mm |

| Sheet Thickness | 0.06-0.6mm |

| Max. image area | 528 x 730mm |

| Plate Size | 677 x 755 x 0.3mm |

| Blanket Size | 740 x 760mm |

| Max. Feeder Pile height | 940mm |

| Max. Delivery Pile height | 780mm |

| Overall Dimensions | 7380 x 2880 x 1870mm |

| Total Power | 23kw |

| Weight | 19700kg |