| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD 4400C

UPG

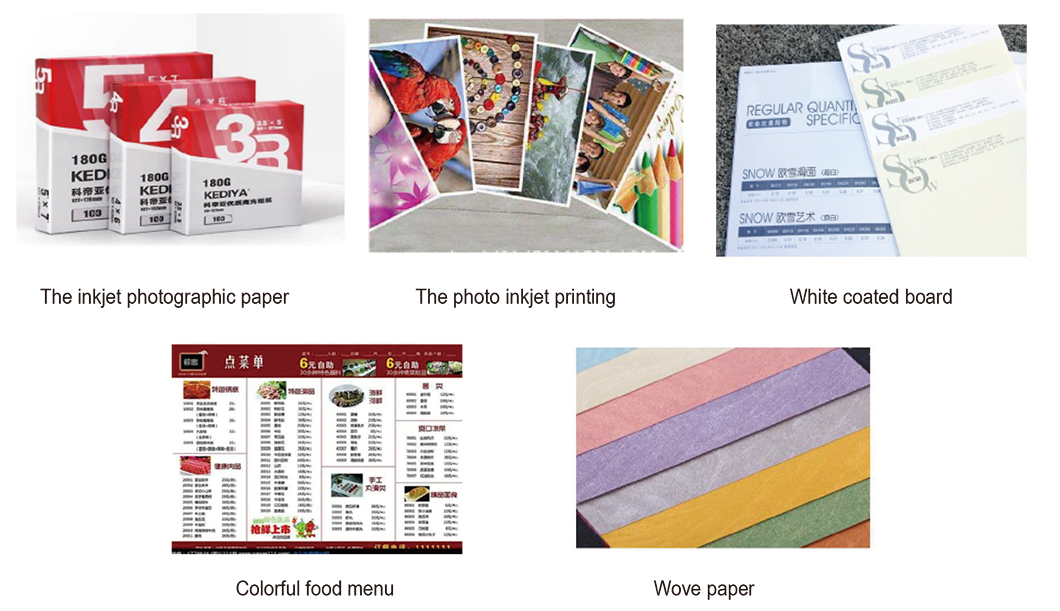

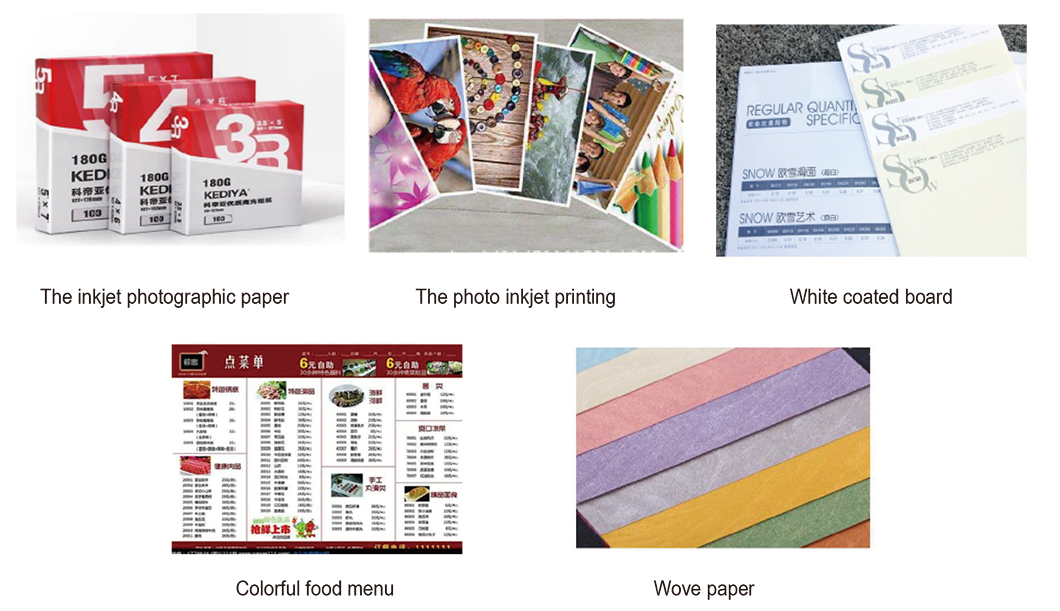

· Using the Tooth-Picking Roller of traditional offset printing and number of technical innovations with bottom tooth-picking and paper tail air suction technologies, available for the parper range of 40-180g; By using the unique structural design, sloved the problem realizing the paper handver after its printing completed, thus ensure the printing accuracy, and achieve the perfect combination of good stability in tradition printing and high efficiency in digital printing.

· The paper front infed and back-end piled design greatly increased machine running efficiency,the option function of no-break paper infed and exit unit realize 24hours of uninterrupted printing.

· Using full servo control system instead of the moto and transfer belt in the tranditional offset printing, can be quick respond to the faults caused by paper jam and double sheet infed problems,Greatly increased the machine running stability.

· After years of independantly R&D of the motion control card, can reach the accuractrly control on all motors of the machine for their stable opperation, up to more than 100 points of real-time sensor control technology realize the perfect control on machine running status, the real-time monitoring on including paper jam, double sheet, paper size changes, paper infed failure, paper exit failure and other detailed problems.

· Adopts independantly double channel air pump for the blowing unit and suction unit of the papaer infeeding part, to realize the independant control on the paper infeeding mechanism, and perfectly achieve the convenience of paper changes in different grams.

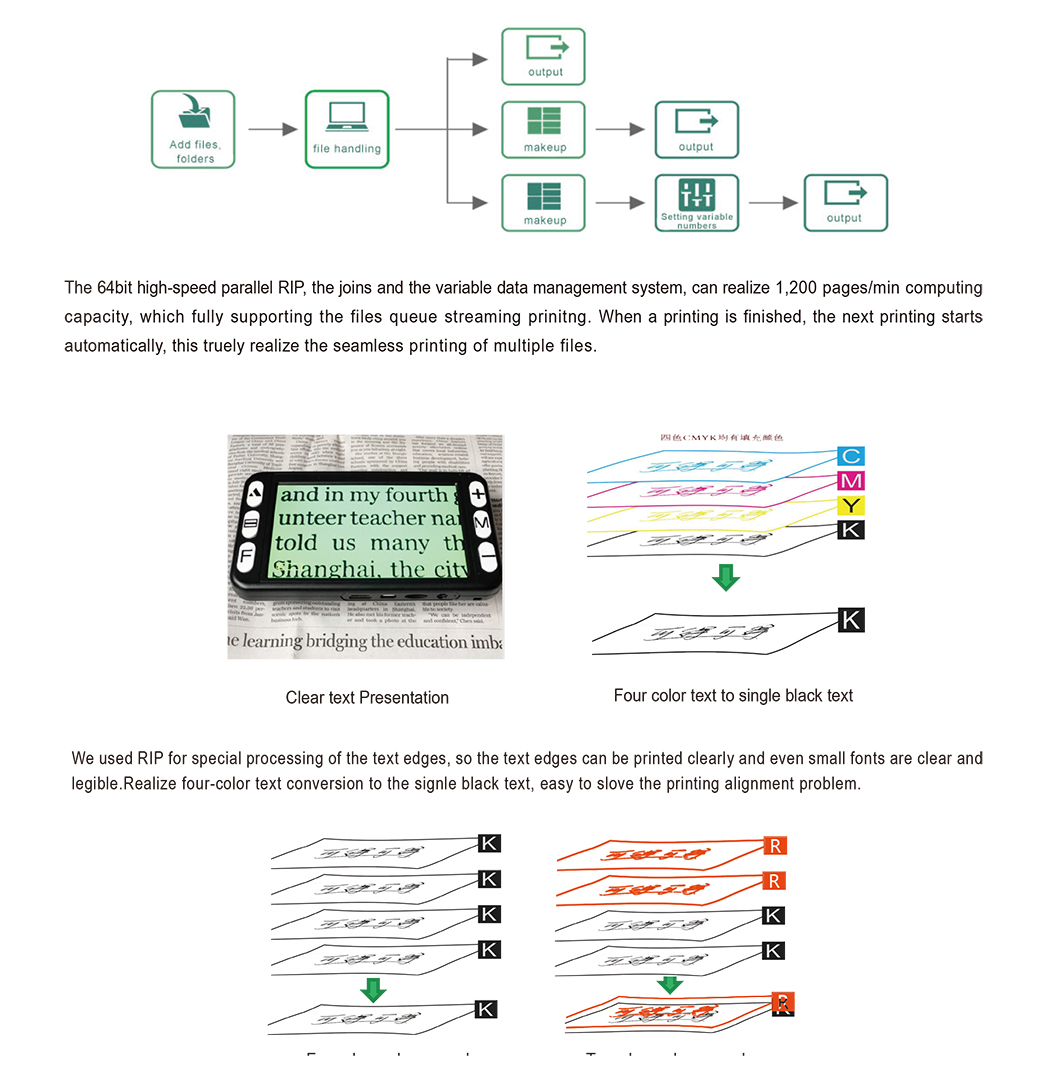

· Jointly developed by W.TECH and Peking University, the 64bit high-speed parallel RIP, the joins and the variable data management system, can realize 1,200 pages/min. computing capacity. fully support the files queue streaming prinitng, when a printing is finished, automatially the next printing started, this truely realize the seamless printing of multiple files.

· Can be comparable to offset printing accuracy and above 7,000pcs/hr A3 size paper stable printing, bring to customer great convenience

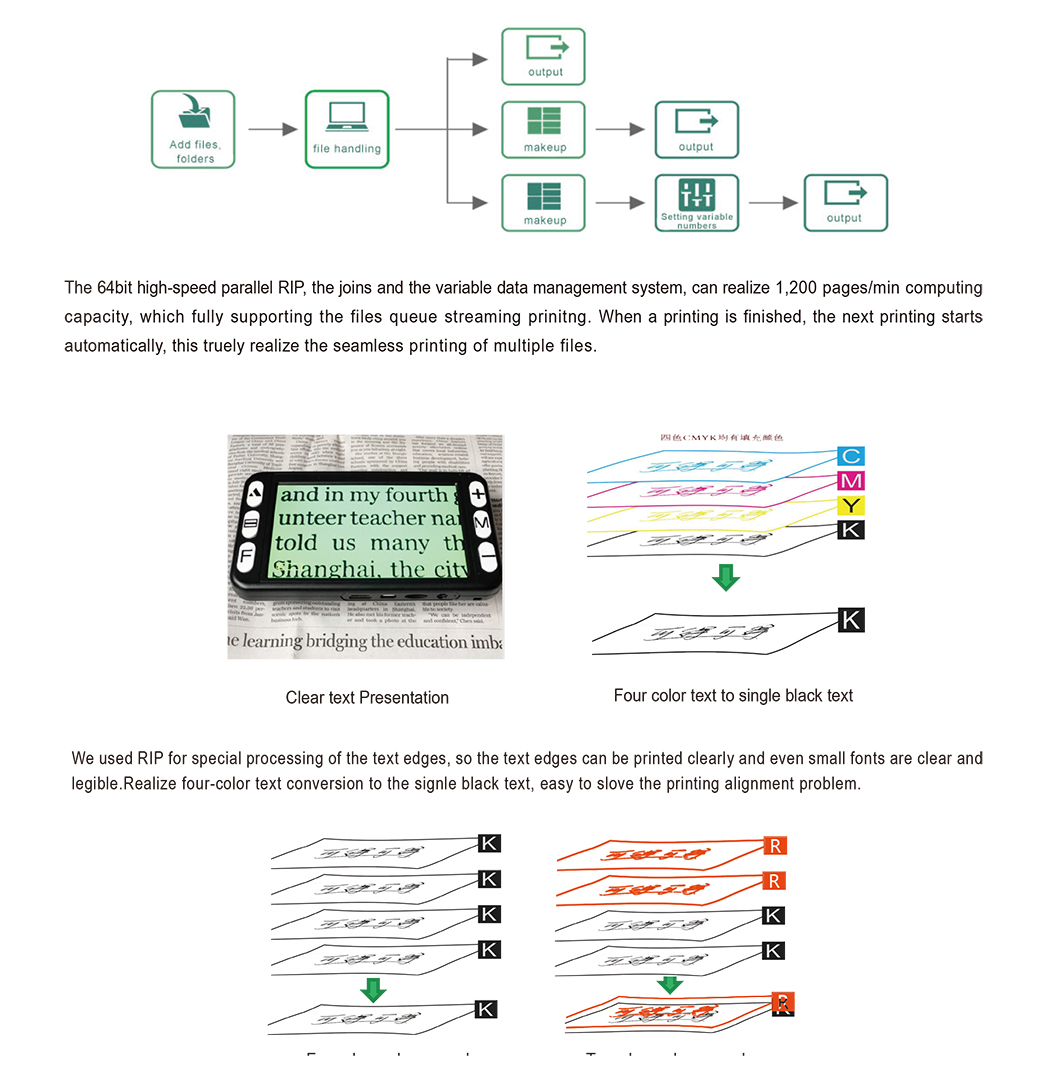

· We used RIP for special processing of the text edges, so the text edges can be printed clearly and even small fonts are clear and legible.

· Realize four-color text conversion to the signle black text, easy to slove the printing alignment problem.

· The variable data typesetting software can be applied for different contents, such as text, data, time, graphic, serial numbers, bar codes, and photo images. its features include template management, layout design, data management, and output preview. this software can be also aplied to variety of prinitng applicaitons, such as security printing, letter printing, label printing, package printing and bar code printing.

Features & Advantages

· Using the Tooth-Picking Roller of traditional offset printing and number of technical innovations with bottom tooth-picking and paper tail air suction technologies, available for the parper range of 40-180g; By using the unique structural design, sloved the problem realizing the paper handver after its printing completed, thus ensure the printing accuracy, and achieve the perfect combination of good stability in tradition printing and high efficiency in digital printing.

· The paper front infed and back-end piled design greatly increased machine running efficiency,the option function of no-break paper infed and exit unit realize 24hours of uninterrupted printing.

· Using full servo control system instead of the moto and transfer belt in the tranditional offset printing, can be quick respond to the faults caused by paper jam and double sheet infed problems,Greatly increased the machine running stability.

· After years of independantly R&D of the motion control card, can reach the accuractrly control on all motors of the machine for their stable opperation, up to more than 100 points of real-time sensor control technology realize the perfect control on machine running status, the real-time monitoring on including paper jam, double sheet, paper size changes, paper infed failure, paper exit failure and other detailed problems.

· Adopts independantly double channel air pump for the blowing unit and suction unit of the papaer infeeding part, to realize the independant control on the paper infeeding mechanism, and perfectly achieve the convenience of paper changes in different grams.

· Jointly developed by W.TECH and Peking University, the 64bit high-speed parallel RIP, the joins and the variable data management system, can realize 1,200 pages/min. computing capacity. fully support the files queue streaming prinitng, when a printing is finished, automatially the next printing started, this truely realize the seamless printing of multiple files.

· Can be comparable to offset printing accuracy and above 7,000pcs/hr A3 size paper stable printing, bring to customer great convenience

· We used RIP for special processing of the text edges, so the text edges can be printed clearly and even small fonts are clear and legible.

· Realize four-color text conversion to the signle black text, easy to slove the printing alignment problem.

· The variable data typesetting software can be applied for different contents, such as text, data, time, graphic, serial numbers, bar codes, and photo images. its features include template management, layout design, data management, and output preview. this software can be also aplied to variety of prinitng applicaitons, such as security printing, letter printing, label printing, package printing and bar code printing.

Features & Advantages

| Model | LQ-MD 4400C |

| Printhead | Using the latest high-speed circulation on demand piezoelectric industrial grade printhead (high-speed, high-precision, circulation, variable point printing) |

| Print size | 440mmx330mm |

| Print color | Single Black, Dula Colors, Full Colors |

| Resolution ratio (dpi) | Full color: 600x600dpi, 600x 800dpi,600 x1200dpi |

| Black and white: 1200 x 1200dpi | |

| Machine size | (H) 1.8mx (L) 4.61mx (W) 1.69m (including base pedal 2.85 m) |

| Control unit | Full Servo |

| Print speed | Designed speed 600ppm, around 7,000pcs/h above (depending on paper's quality, thickness and environment, etc.) |

| Suitable paper | Woodfree paper/News paper/inkjet Coated Paper/Carbon Free Paper |

| Model | LQ-MD 4400C |

| Printhead | Using the latest high-speed circulation on demand piezoelectric industrial grade printhead (high-speed, high-precision, circulation, variable point printing) |

| Print size | 440mmx330mm |

| Print color | Single Black, Dula Colors, Full Colors |

| Resolution ratio (dpi) | Full color: 600x600dpi, 600x 800dpi,600 x1200dpi |

| Black and white: 1200 x 1200dpi | |

| Machine size | (H) 1.8mx (L) 4.61mx (W) 1.69m (including base pedal 2.85 m) |

| Control unit | Full Servo |

| Print speed | Designed speed 600ppm, around 7,000pcs/h above (depending on paper's quality, thickness and environment, etc.) |

| Suitable paper | Woodfree paper/News paper/inkjet Coated Paper/Carbon Free Paper |