- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-PY

UPG

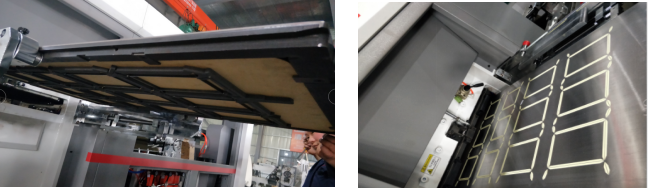

Machine Advantages:

1.Directly coupled servo motor driving with reduce motor, which can make the mechanical speed up to 260 times/min.

2.Enhanced machine core to take much more pressure, up to 350T.

3.Positioning block in movable platform we add one more positioning block in movable platform. It makes the pressure of the platform more stable, and endurable.

4.Oil circuit and oil detection system.

The outside oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil

5. Machine adopt IOT technology. Not only Customer can supervise the machine operation situation on Mobile APP, manufactuer also can through this app to fullful remote control to provide the aftersale service. So both of two parts can save the service time and money.

6. Paper blocked alarm system. The new design adds the alarm system to make the machine stop when paper feeding blocked.

7.Paper feeding balance regulator add new type paper feeding balance regulator to adjust he minor unbalance situation.

8.Paper roll tension system use proportional valve control, automatic tension control,and easy operation.

Machine Advantages:

1.Directly coupled servo motor driving with reduce motor, which can make the mechanical speed up to 260 times/min.

2.Enhanced machine core to take much more pressure, up to 350T.

3.Positioning block in movable platform we add one more positioning block in movable platform. It makes the pressure of the platform more stable, and endurable.

4.Oil circuit and oil detection system.

The outside oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil

5. Machine adopt IOT technology. Not only Customer can supervise the machine operation situation on Mobile APP, manufactuer also can through this app to fullful remote control to provide the aftersale service. So both of two parts can save the service time and money.

6. Paper blocked alarm system. The new design adds the alarm system to make the machine stop when paper feeding blocked.

7.Paper feeding balance regulator add new type paper feeding balance regulator to adjust he minor unbalance situation.

8.Paper roll tension system use proportional valve control, automatic tension control,and easy operation.

Type | LQ-PY-950 | LQ-PY- 1200 | LQ-PY- 1300 |

Mechanical running speed | 150-260times/min | 150-240times/min | 100-210 times/min |

Paper Convey Width | 950-300mm | 1200-300mm | 1300-400mm |

Maximum cutting size | 950 x540mm | 1200 x640mm | 1300 x750mm |

Total Weight: | 7000kgs | 9000kgs | 10500kgs |

Overall Dimension: | 4.5 x 2. 1 x 1.85m | 4.7x2.3x 1.85m | 4.6x2.3x2.1m |

Suitable Material: | 100-800g/m2 white cardboard, PE coated paper, Kraft paper.etc | ||

Total Power and Air source: | 12KW;0.6Mpa; 0.3m³/min; | 15.5KW; 0.6Mpa; 0.3m³/min; 380V/50HZ (other voltage can be customized) | |

Max Roll paper diameter | 1600mm

| ||

Cut Precision: | ± 0.20mm | ||

Type | LQ-PY-950 | LQ-PY- 1200 | LQ-PY- 1300 |

Mechanical running speed | 150-260times/min | 150-240times/min | 100-210 times/min |

Paper Convey Width | 950-300mm | 1200-300mm | 1300-400mm |

Maximum cutting size | 950 x540mm | 1200 x640mm | 1300 x750mm |

Total Weight: | 7000kgs | 9000kgs | 10500kgs |

Overall Dimension: | 4.5 x 2. 1 x 1.85m | 4.7x2.3x 1.85m | 4.6x2.3x2.1m |

Suitable Material: | 100-800g/m2 white cardboard, PE coated paper, Kraft paper.etc | ||

Total Power and Air source: | 12KW;0.6Mpa; 0.3m³/min; | 15.5KW; 0.6Mpa; 0.3m³/min; 380V/50HZ (other voltage can be customized) | |

Max Roll paper diameter | 1600mm

| ||

Cut Precision: | ± 0.20mm | ||

(option)-1:( Airshaftless system)

1.It bears much more weight than standard airshaft.

2.It fits any roll paper core sizes.

(option)-2:(non-stop collect system)

1.Instead of stop running to move the plastic pallet from the machine,

2.It saves insert the metal pallet during machine is running, to save the product collect time.

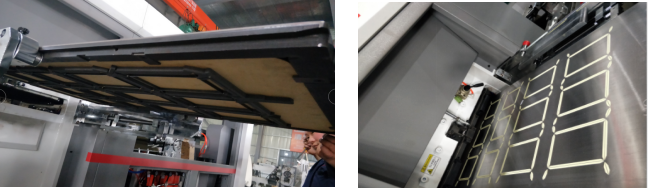

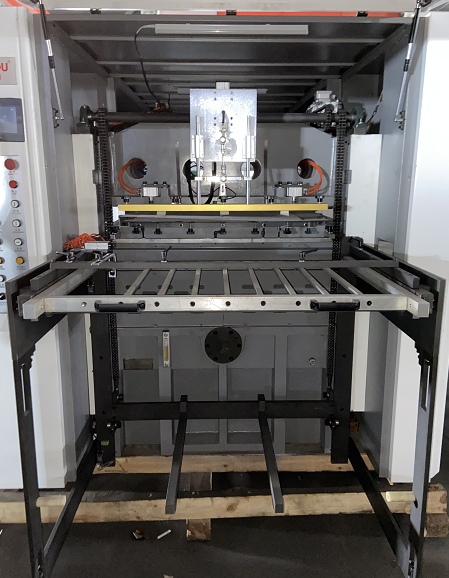

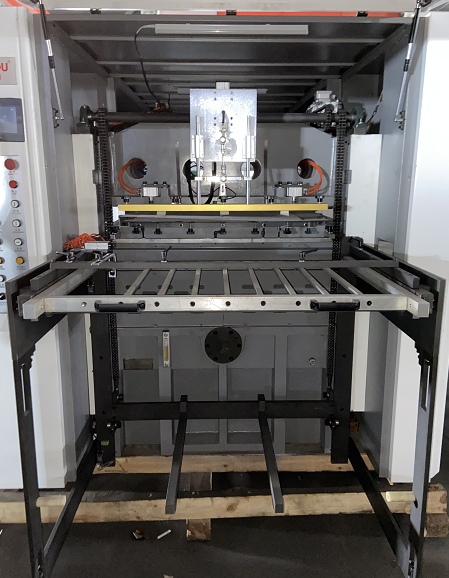

(option)-3: male and female plate make the mold change easier.

(option)-1:( Airshaftless system)

1.It bears much more weight than standard airshaft.

2.It fits any roll paper core sizes.

(option)-2:(non-stop collect system)

1.Instead of stop running to move the plastic pallet from the machine,

2.It saves insert the metal pallet during machine is running, to save the product collect time.

(option)-3: male and female plate make the mold change easier.