| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

LQ-MD P9

UPG

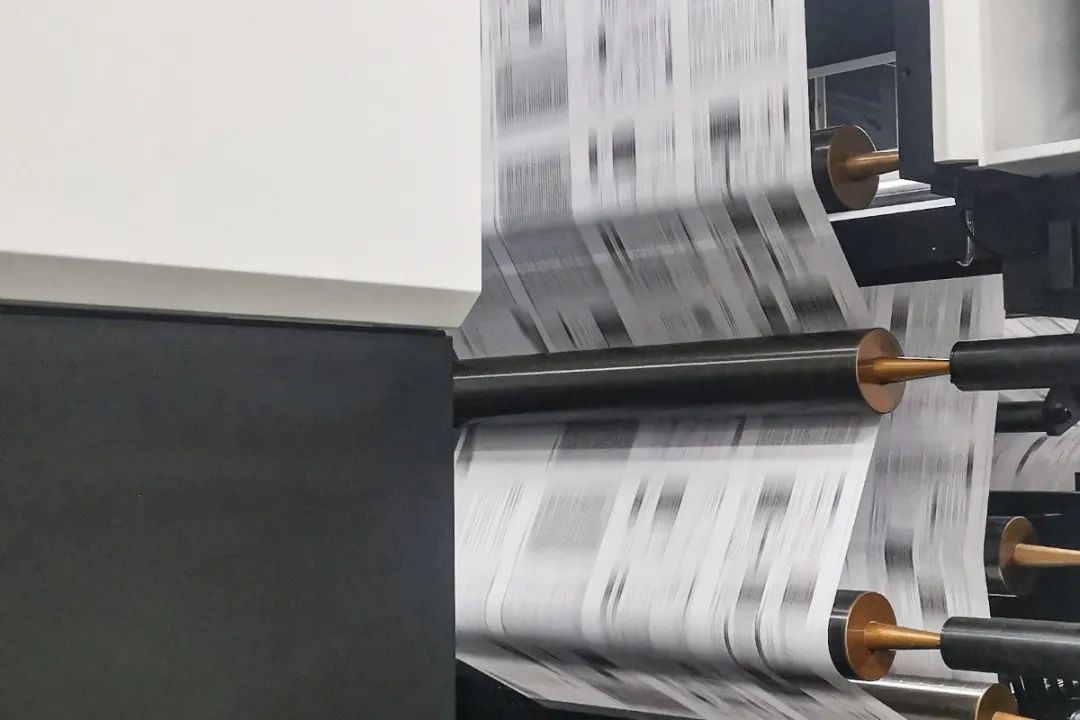

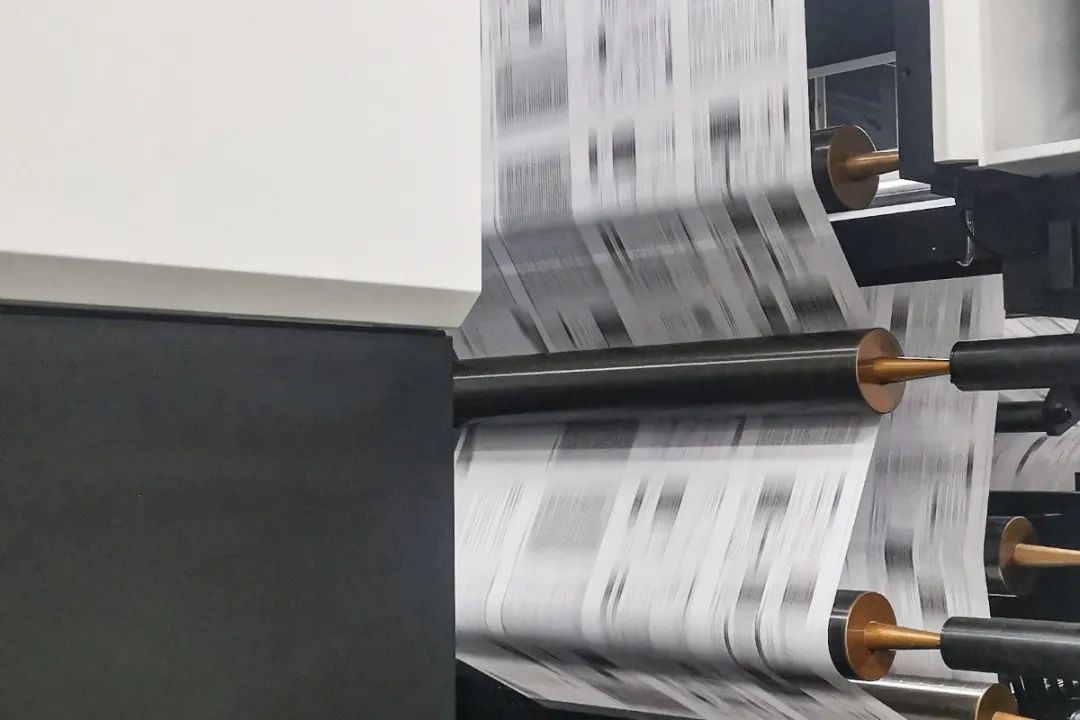

MultiSpeeder digital inkjet technology

Make production more stable and reliable.

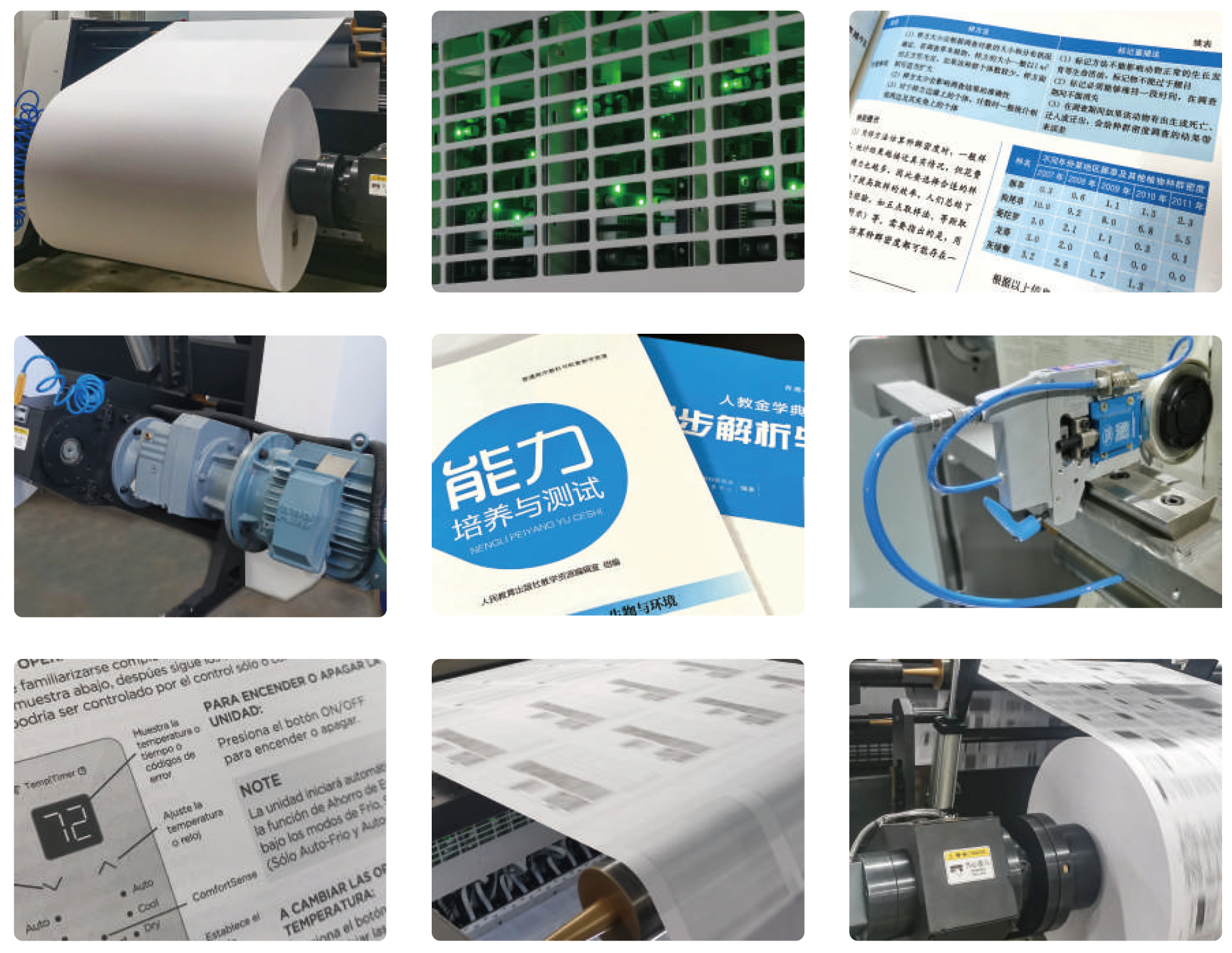

With a printing format of up to 890 mm, the P9 uses an industrial piezoelectric nozzle to achieve high-speed, high-quality printing at 225 m/min for conventional paper with the help of UPG MultiSpeeder printing technology.

UPG M-Plusm variable ink drop technology effectively inhibits the nozzle skew needle plugging phenomenon, to ensure that the nozzle is always in the best working condition. Steady state ink supply technology and active and passive cleaning technology of nozzle ensure the continuous stability of ink supply and active self-cleaning of jet hole. Achieve 7×24 hours stable and reliable continuous production.

PrintManager process software

Make work more easy

The UPG Print Manager workflow software adopts HighScreen technology to achieve high speed and high quality screen printing; text anti-aliasing and edge sharpening techniques to ensure smooth and neat edges of text lines.

The UPG SmartColor color management system adopts color curve LAB intelligent generation technology, combined with guided color management, ICC profile generation and optimization technology, and ink saving control technology, to achieve high color space and rich color presentation under low ink volume.

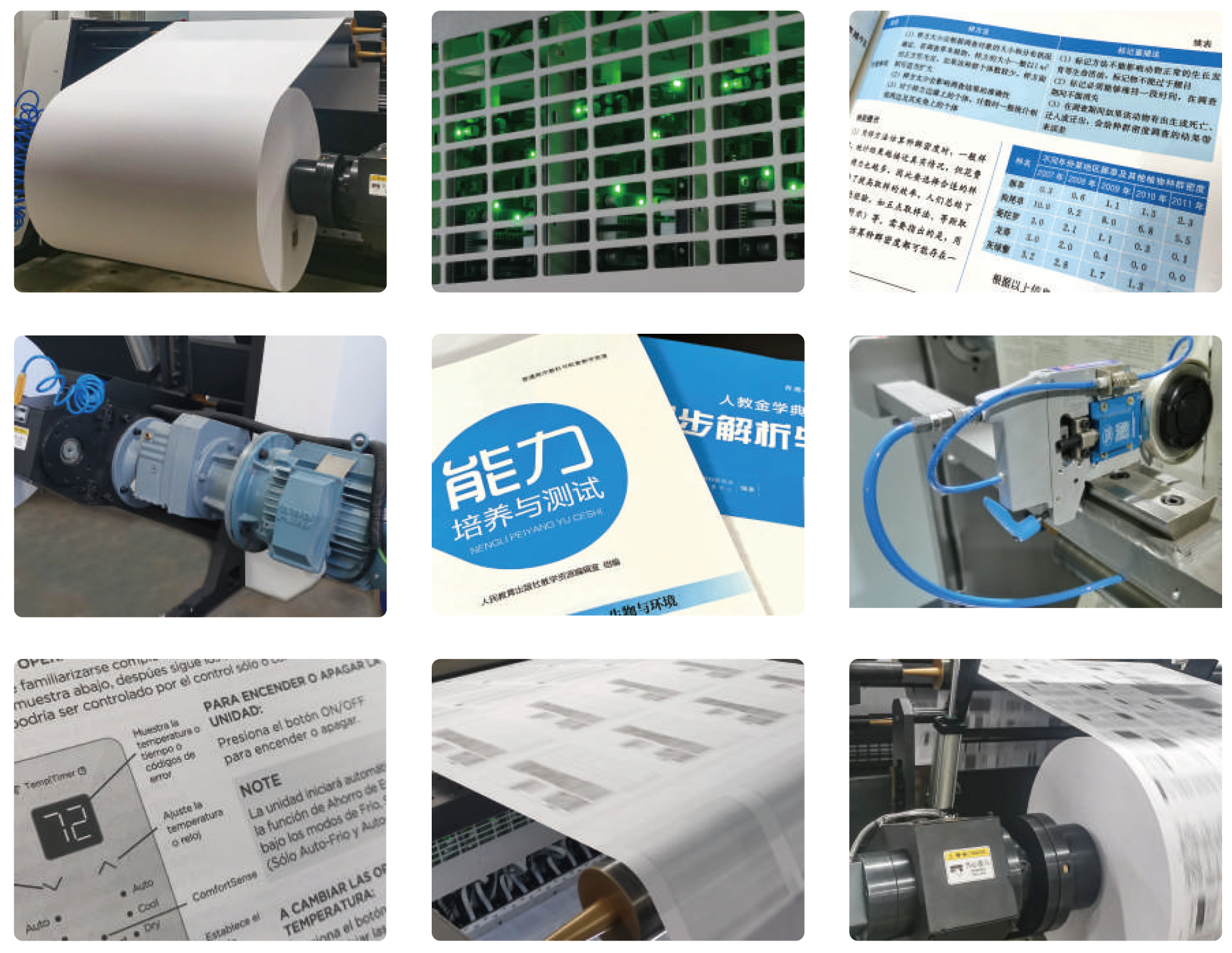

SpeedStar high speed printing platform

Make paper more adaptable

The UPG SpeedStar high speed printing platform is suitable for conventional offset paper in the 440-940 mm wide range of 28-157 gsm, easily coping with various paper types such as ordinary woodfree paper, lightweight paper, forest paper, newspaper, rice paper, carbon free paper, etc.

Fast web paper change is possible; 440 mm double winding can be achieved according to customer needs, to achieve a high-speed and stable state of paper feed from beginning to end.

BreezeDry drying system

Make production more energy efficient

The UPG BreezeDry system adopts industry-leading circulating hot air drying technology to achieve accurate constant temperature control, internal and external circulation of return air and thermal energy recycling, ensuring fast drying of paper with ultra-low power consumption.

UPG High Adaptation Ink for superior quality

Developed for traditional offset paper, UPG High Adaptation Ink offers a wide range of applications, high color concentration, fast drying speed and excellent anti-back penetration performance. The ink meets the national VOCs emission standards; it has passed US California 65, PFAS, REACH (CE), REACH (UK) and other certifications, and has passed a series of safety transportation certifications such as aviation and maritime transportation.

UPG High Adaptation Ink has excellent matching with the nozzle system, which can effectively reduce the nozzle blockage and skew phenomenon caused by long-term exposure. Combined with the MultiSpeeder™ technology, the P9 digital rotary press can achieve instant drying at a high speed of 225 m/min for conventional book coverage offset paper business, even if the drying system is not turned on.

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

MultiSpeeder digital inkjet technology

Make production more stable and reliable.

With a printing format of up to 890 mm, the P9 uses an industrial piezoelectric nozzle to achieve high-speed, high-quality printing at 225 m/min for conventional paper with the help of UPG MultiSpeeder printing technology.

UPG M-Plusm variable ink drop technology effectively inhibits the nozzle skew needle plugging phenomenon, to ensure that the nozzle is always in the best working condition. Steady state ink supply technology and active and passive cleaning technology of nozzle ensure the continuous stability of ink supply and active self-cleaning of jet hole. Achieve 7×24 hours stable and reliable continuous production.

PrintManager process software

Make work more easy

The UPG Print Manager workflow software adopts HighScreen technology to achieve high speed and high quality screen printing; text anti-aliasing and edge sharpening techniques to ensure smooth and neat edges of text lines.

The UPG SmartColor color management system adopts color curve LAB intelligent generation technology, combined with guided color management, ICC profile generation and optimization technology, and ink saving control technology, to achieve high color space and rich color presentation under low ink volume.

SpeedStar high speed printing platform

Make paper more adaptable

The UPG SpeedStar high speed printing platform is suitable for conventional offset paper in the 440-940 mm wide range of 28-157 gsm, easily coping with various paper types such as ordinary woodfree paper, lightweight paper, forest paper, newspaper, rice paper, carbon free paper, etc.

Fast web paper change is possible; 440 mm double winding can be achieved according to customer needs, to achieve a high-speed and stable state of paper feed from beginning to end.

BreezeDry drying system

Make production more energy efficient

The UPG BreezeDry system adopts industry-leading circulating hot air drying technology to achieve accurate constant temperature control, internal and external circulation of return air and thermal energy recycling, ensuring fast drying of paper with ultra-low power consumption.

UPG High Adaptation Ink for superior quality

Developed for traditional offset paper, UPG High Adaptation Ink offers a wide range of applications, high color concentration, fast drying speed and excellent anti-back penetration performance. The ink meets the national VOCs emission standards; it has passed US California 65, PFAS, REACH (CE), REACH (UK) and other certifications, and has passed a series of safety transportation certifications such as aviation and maritime transportation.

UPG High Adaptation Ink has excellent matching with the nozzle system, which can effectively reduce the nozzle blockage and skew phenomenon caused by long-term exposure. Combined with the MultiSpeeder™ technology, the P9 digital rotary press can achieve instant drying at a high speed of 225 m/min for conventional book coverage offset paper business, even if the drying system is not turned on.

Company Profile:

Superior:

A trading brand enterprise which is invested by industry and joint industry and trade.

ShangHai UPG International Industry & Trade Group Co., Ltd. is a professional trading company which is invested by UP Group's key branch enterprises together, the company has become the most active and influential brand in the printing and packaging machinery industry in China.

We own high efficiency, high quality, stable and professional trade working team.

In the long-term practice of trading, we foster and establish a multilingual, professional, high diathesis and qualification staff team, which form the biggest and most powerful trading enterprises in this industry. Among our working team, 97% obtain the associate degree and bachelor degree, 40% own intermediate level professional titles, master degree or above.

We adhere the philosophy that "over-value service, pioneering and pragmatic, and Win-win cooperation".

We start from innovation system, improve the institutional mechanism, gradually cultivating and forming a value pursuit, and enterprise culture which specialize in "Honest and trustworthy, Diligent and promising, Pursue excellence and efficiency, over-value service". We always ensure the quality of the products and service, establish long-term and stable relations of cooperation with domestic suppliers as well as our foreign customers for mutual benefits.

Superiority of abundant resource, matching into a line, high optionality.

We centred on printing machinery manufacturing and have established long term strategic collaborations with more than 50 cost-effective, high quality and reputation brand enterprises and factories, which cover printing and packaging, food and pharmaceutical packaging, printing consumables and rubber& plastic machinery, and form a multi-category, multispecies and multilevel integrated superiority and provide a convenient service channel for foreign customers.

Well planned, high input, extensive coverage exhibition publicity.

The huge investment of more than 20 international professional exhibitions and more than one billion sales amount per year make our company known overseas and be of high reputation in domestic and abroad market.

Strengthen channel building, service to global customers, multiple trading strategic pattern.

Through several years' effort, we have exported products to more than 80 countries (not only Asia but also Europe, Africa, South America, North America and Oceania) and have established long term strategic collaborations with distributors and sales channels in more than 40 countries and regions, which play an important role for open foreign market and maintain service terminal clients.

Our Customers:

Exhibitions:

Export Markets:

UP Group's products have been exported to more than 80 countries.

In Southeast Asia, its products cover Thailand, Indonesia, Singapore, Malaysia, Brunei, the Philippines, Japan, Korea, Vietnam, Cambodia, India, Sri Lanka, Nepal, Dubai, Kuwait, Saudi, Syria, Lebanon, Maldives, Bahrain, Jordan, Sudan, Mongolia, Myanmar, Pakistan, Iran, Turkey and Bangladesh.

In European, its products cover Australia, New Zealand, Britain, France, Germany, Italy, Spain, Portugal, Georgians, Slovakia Finland, Poland, the Czech Republic, Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Sweden, Bosnia, Herzegovina and Albania

In Africa, its products cover South Africa, Kenya, Ethiopia, Egypt, Morocco, Algeria, Tunisia, Madagascar, Mauritius, Nigeria, Ivory Coast, Ghana, Mali, Liberia and Cameroon.

In America, its products cover The United States, Canada, Mexico, Panama, Costa Rica, Brazil, Argentina, Columbia, Bolivia, Uruguay, Paraguay, Chile, Peru, Ecuador and Honduras.

Among these regions, we have more than 46 stable distributors and partners for many years.

Packaging and Shipping:

Our Services:

Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

| Printing Method | Duplex monochrome / Duplex two color / Duplex four color | |

| Maximum Paper Width | 940 mm | |

| Maximum Printing Width | 890 mm | |

| Maximum Printing Speed | 225 m/min | |

| Paper Weight | 28–157 g/m² | |

| Maximum Roll Diameter | 1200 mm | |

| Nozzle Type | Industrial Piezo drop-on-demand | |

| Printing Accuracy | Equivalent to offset 175 lpi ~ 200 lpi | |

| Printing Resolution | 600 dpi × 600 dpi Four levels of grayscale | 1200 dpi x 1200 dpi |

| Printing Speed | 225 m/min (600 dpi × 600 dpi) 165 m/min (600 dpi × 600 dpi, four levels of grayscale) | 200 m/min(1200 dpi x 600 dpi) 150 m/min (1200 dpi x 900 dpi) 100 m/min (1200 dpix 1200 dpi) |

| Print Control System | UPG Inkjet Speeder board system UPG MultiSpeeder technology UPG M-Plus technology | UPG Inkjet Speeder board system |

| Process Software | UPG PrintManager technology UPG HighScreen technology UPG SmartColor technology | |

| Paper Type | Plain paper, coated paper, ground-wood paper, recycled paper, offset paper, newspaper, China rice paper, no carbon paper, digital paper, others | |

| Ink | UPG High Adaptation Ink | |

| Drying Method | UPG BreezeDry system | |

| Paper Walking Platform | UPG SpeedStar high speed printing platform; Reel to reel; Flatness clamp head paper; By adding a middle split system, the machine can rewind two 440 mm-wide rolls simultaneously | |

| Weight | 17 t | |

| Air Source Requirements | 0.6–0.8 MPa | |

| Machine Size | Machine size: W 12000 * D 4500 * H 2600mm Installation space: W 15000 * D 7500 * H 3000mm | |

| Environment Humidity | Environment Temperature: 20–24 °C (with no sudden temperature change within a short period) Environment Humidity: 45–65 % RH (no condensation) | |

| Rated Power | 43 kW / 51 kW / 67 kW (monochrome / two-color / four-color) | |

| Printing Method | Duplex monochrome / Duplex two color / Duplex four color | |

| Maximum Paper Width | 940 mm | |

| Maximum Printing Width | 890 mm | |

| Maximum Printing Speed | 225 m/min | |

| Paper Weight | 28–157 g/m² | |

| Maximum Roll Diameter | 1200 mm | |

| Nozzle Type | Industrial Piezo drop-on-demand | |

| Printing Accuracy | Equivalent to offset 175 lpi ~ 200 lpi | |

| Printing Resolution | 600 dpi × 600 dpi Four levels of grayscale | 1200 dpi x 1200 dpi |

| Printing Speed | 225 m/min (600 dpi × 600 dpi) 165 m/min (600 dpi × 600 dpi, four levels of grayscale) | 200 m/min(1200 dpi x 600 dpi) 150 m/min (1200 dpi x 900 dpi) 100 m/min (1200 dpix 1200 dpi) |

| Print Control System | UPG Inkjet Speeder board system UPG MultiSpeeder technology UPG M-Plus technology | UPG Inkjet Speeder board system |

| Process Software | UPG PrintManager technology UPG HighScreen technology UPG SmartColor technology | |

| Paper Type | Plain paper, coated paper, ground-wood paper, recycled paper, offset paper, newspaper, China rice paper, no carbon paper, digital paper, others | |

| Ink | UPG High Adaptation Ink | |

| Drying Method | UPG BreezeDry system | |

| Paper Walking Platform | UPG SpeedStar high speed printing platform; Reel to reel; Flatness clamp head paper; By adding a middle split system, the machine can rewind two 440 mm-wide rolls simultaneously | |

| Weight | 17 t | |

| Air Source Requirements | 0.6–0.8 MPa | |

| Machine Size | Machine size: W 12000 * D 4500 * H 2600mm Installation space: W 15000 * D 7500 * H 3000mm | |

| Environment Humidity | Environment Temperature: 20–24 °C (with no sudden temperature change within a short period) Environment Humidity: 45–65 % RH (no condensation) | |

| Rated Power | 43 kW / 51 kW / 67 kW (monochrome / two-color / four-color) | |